EPSO vice-president: developing countries to play key role in climate-friendly bioenergy

Much is expected of biotechnology this century. The prospect of a growing world population and increasing energy needs has prompted plant scientists to design new crops that must make it possible to both feed the planet and provide it with climate friendly bioenergy in a sustainable way. In the following interview, Dirk Inzé, Plant Systems Biology professor at the University of Ghent (Belgium), co-founder of biotech firm Crop Design (recently acquired by chemical giant BASF) and vice-president of the European Plant Science Organisation (EPSO) discusses some of these challenges.

Much is expected of biotechnology this century. The prospect of a growing world population and increasing energy needs has prompted plant scientists to design new crops that must make it possible to both feed the planet and provide it with climate friendly bioenergy in a sustainable way. In the following interview, Dirk Inzé, Plant Systems Biology professor at the University of Ghent (Belgium), co-founder of biotech firm Crop Design (recently acquired by chemical giant BASF) and vice-president of the European Plant Science Organisation (EPSO) discusses some of these challenges.Inzé's team at the Flanders Interuniversity Institute for Biotechnology (VIB) played an important role in mapping the poplar genome and in several other projects under the Joint Genome Institute which investigates energy crops. The VIB was founded by the father of modern plant bio-engineering, Marc Van Montagu (previous post). The breakthrough work of Inzé and the organisation of Ghent's plant sciences has contributed much to Belgium achieving the the title of being the 'world's best place' to work in scientific research (more here).

In the interview, Inzé says the developing world stands to gain from its enormous potential to produce biofuels and energy crops. The scientist also warns that if Europe doesn't ease its stance on genetically modified organisms (GMOs), its citizens will find it impossible to buy affordable food in the future.

Professor Inzé, you are focused on increasing the productivity and yield of crops. Can you describe the main challenges?

In the next decades we will have to feed three billion more people than today. Their living standard will be higher than that of the current generation, so they will want to consume more meat. Per kilogram of animal protein, you need seven kilograms of grain. The yield per hectare of crops will therefor have to increase significantly. Experiments with prototypes of genetically modified crops show we can increase production by 50 percent without extra inputs of nitrogen and other fertilizers.

Which crops are we talking about?

The main grain crops, like rice and maize. There is a tremendous amount of natural variation in plant growth. Some species remain tiny, while others grow in a spectacular manner, most notably a type of bamboo, the record holder - you can literally see it grow with the naked eye, at 1.2 meters per day. This opens interesting perspectives.

Isn't plant growth regulated by a whole range of genes?

Of course, and this is where systems biology proves to be so useful: we try to grasp the complexities of the entire process. It's possible to learn to understand the workings of all the components of an airplane, but really understanding how it stays in the air is something else. In the same way we try to gain insight into life in its full complexity, and to get there we start by learing what happens to the entire system when you push one of its buttons. It's excruciatingly complex, but we are making progress.

How many patents do you and your biotech team hold?

A very large number, and this is important because our investments must be protected. No company will ever invest tens of millions of euros in research and development if it can't enjoy the fruits of its own innovations. In 1998 we launched Crop Design. Last year we sold it to chemical giant BASF, which wants to commercialize our developments together with Monsanto. I expect our first genetically modified high yield crops to be on the market by 2013.

The public doesn't have a problem with genetic experiments in the field of human medicine. But in agriculture this is another matter, especially in Europe.

This is mainly a political problem. A select group of organisations has taken the issue of genetically modified organisms as a rallying point, uses it to scare people and to gain them for their cause. That's their only raison d'être. But you cannot apply the precautionary principle - which tells you to be careful for the effects of innovations and scientific interventions - endlessly. This stifles human progress. There are hundreds of scientific studies which prove our technologies are safe. Each day, hundreds of millions of people eat GMOs. You cannot continue to say that this is dangerous when you see, on a daily basis, that it's not.

Why don't you stress the environmental benefits of GMOs more often?

We try to do this, continuously. But organisations like Greenpeace and others refuse to understand that our technologies serve their cause. Isn't it useful to develop plants that can defend themselves against pests, so that we can radically cut back our use of pesticides? Our products aren't merely commercially interesting, they make sense from an ecological point of view.

Agriculture as it is being practised today can be quite polluting because of the heavy use of fertilizers. Moreover, fertilizers become ever more expensive because of high energy prices. With our technologies we can make agriculture both much cleaner and more efficient.

We are also developing dedicated energy crops for biofuels, which will allow us to make fuels in such a way that they do not impact food markets. This is important to all of us:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biotechnology :: GMO :: energy crops :: developing countries :: Europe ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biotechnology :: GMO :: energy crops :: developing countries :: Europe :: Europe remains very skeptical and doesn't seem to be willing to ease its stance on GMOs.

I think things are changing. Europe doesn't have a choice because in the Americas and Asia the technology is gaining ground. Europe will start to lose and suffer if it can't compete in this field.

Some say that large companies are responsible for pushing a complex net of regulations in order to make it impossible for small biotech companies to compete.

This analysis isn't correct, I feel. Look at the pharmaceutical sector: small companies don't get any further than the first stages which consist of testing a new product. It then costs around 1 billion dollars to get such a new product to market. This is too much to ask of small biotech companies. In the agricultural sector it takes about 80 million euros to make something useful out of an innovation. These are gigantic sums of money. The point is that scale-advantages are crucial but can only be reaped by large companies. This trend is irreversible.

Do your patents get attacked?

Yes, all the time. It can take ages before you are granted a patent. My predecessors, professors Marc Van Montagu and Jef Schell, are the founding fathers of plant genetic engineering. Worldwide, some 110 million hectares of land grow crops based on their technologies. But it took them 20 years to get their final patents. Procedural attacks kept delaying the recognition. Only lawyers got better of this. But the simple fact remains: the patent system is the only approach that allows investors to get a return on their investments in this type of research.

But it is very important to understand the following: there is a consensus on the fact that genes as such should not be patentable, only innovations that allow you to work with these genes. The search for ways to side-step the full implications of a patented process often leads to new innovations. This way patents stimulate research, through scientific competitition.

In the patent for so-called 'golden rice' - the crop containing a gene that stimulates the production of the vitamin A precursor - it is stipulated that the technology must be made available for free to developing countries. Is this a good approach?

I think so. Billions of people eat white rice, which doesn't contain sufficient amounts of vitamin A. This can lead to blindness, especially amongst children. By inserting a gene from the wild daffodil into it, the rice produces beta-carotene. All studies demonstrate that this is a very safe product, but still it doesn't find its way to market. Syngenta, which developed the crop, is now offering it for free to countries whose people enjoy average living standards.

But is this profitable? Vitamin A deficiency manifests itself most amongst people in the poorest countries, doesn't it?

This is indeed the case and the return on investment would be low if the crop were to be sold in these countries. The same problem can be found in the field of tropical medicine - drugs are costly to develop but the purchasing power of those who need these medicines is too low to make an investment viable. This is why I think it would be useful to create separate international organisations both in the field of agriculture and in medical sciences to tackle this impasse.

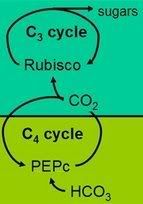

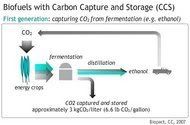

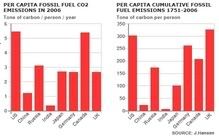

But the third world does have an enormous potential in another sector: the field of bioenergy which must be tapped urgently as an alternative to fossil fuels. Plants convert the greenhouse gas CO2 into food and energy. Many developing countries have suitable agro-climatic conditions and could thus play a key role in producing climate friendly energy.

Shouldn't we be planting more trees here in Europe and Belgium?

Absolutely, that too. At our institute we have developed a fantastic technology to produce bioenergy from poplar trees [note: Inzé and his collegues helped map the genome of the poplar tree - the first tree to have had its entire genetic profile published; the effort was part of the international Joint Genome Institute's research into genomics of bioenergy crops - previous post; on the basis of their research they designed a poplar with low lignin and high biomass yields]. Crops like rapeseed, which receive a lot of attention today, are less interesting for biofuels, because they require too many inputs. A tree grows all by itself. With minimal inputs you get a maximal output. We have now filed for a permission to trial our genetically modified energy poplar in the field.

Aren't you afraid that people will resist this? It's been five years since the last GMO field trials in our country.

Luckily, we play a role on a world scale. Europe's agriculture can only survive because of massive subsidies. If the Union doesn't relax its rules for new technologies, European citizens will no longer be able to buy food. The Food & Drug Administration (FDA) in the United States, which regulates new technologies and approves new products, is an excellent institution, an oracle of scientific common sense. We urgently need a similar body here in Europe.

Today we are too dependent on the vagaries of idiosyncratic opinions in Europe - of what the German Greens think at a particular moment in time or of a sentiment uttered by the new french President.

Translated from Dutch for Biopact.

Image: sun setting over a sugarcane field in Malawi. A new dawn for Africa?

References:

Dirk Draulans, "Niemand mag genen bezitten" [Nobody should own genes], Knack, pp. 89-94, December 19, 2007.

Biopact: Celebrity spotting: Marc Van Montagu and GM energy crops - July 05, 2007

Biopact: The first tree genome is published: Poplar holds promise as renewable bioenergy resource - September 14, 2006

Biopact: Moss genome sequenced: shows how aquatic plants adapted to dry land - key to development of drought-tolerant energy crops, cellulosic biofuels - December 14, 2007

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Sweet potatoes are being

Sweet potatoes are being

How a changing climate can affect ecosystems is an important and timely question, especially considering the recent global rise in greenhouse gases. Now, in an

How a changing climate can affect ecosystems is an important and timely question, especially considering the recent global rise in greenhouse gases. Now, in an

Forestry engineers from North Carolina State University (NCSU) are

Forestry engineers from North Carolina State University (NCSU) are

Japanese engine and agricultural machinery manufacturer Yanmar

Japanese engine and agricultural machinery manufacturer Yanmar

Brussels-based chemical giant Solvay

Brussels-based chemical giant Solvay  Malawi's much discussed

Malawi's much discussed

In the search for renewable and alternative aviation fuels, the US Air Force (USAF)

In the search for renewable and alternative aviation fuels, the US Air Force (USAF)  A few years ago, a group of socially engaged students decided to explore the potential of biofuels to contribute to sustainable development in the countries of the South, and to investigate whether they could lead to new agricultural opportunities for farmers there. Biopact had a vision: in a world of ever increasing oil prices and the need to address climate change, developing countries with lots of land resources and in search of new agricultural markets would enjoy their comparative advantages and produce fuels from energy crops for their own and for international markets. Given their abundant natural resources and the lack of these in energy hungry economies, a relationship connecting efficient producers in the South to wealthy consumers in the North would have been an interesting option. Such a 'win-win' could have brought rural development in places where it is much needed, and perhaps a form of global social and environmental justice.

A few years ago, a group of socially engaged students decided to explore the potential of biofuels to contribute to sustainable development in the countries of the South, and to investigate whether they could lead to new agricultural opportunities for farmers there. Biopact had a vision: in a world of ever increasing oil prices and the need to address climate change, developing countries with lots of land resources and in search of new agricultural markets would enjoy their comparative advantages and produce fuels from energy crops for their own and for international markets. Given their abundant natural resources and the lack of these in energy hungry economies, a relationship connecting efficient producers in the South to wealthy consumers in the North would have been an interesting option. Such a 'win-win' could have brought rural development in places where it is much needed, and perhaps a form of global social and environmental justice. For the time being, we will only support the small scale, local use of biofuels for communities that decide for themselves - in full sovereignty and independence - that it makes sense to do so, for them and for whichever reason (improved farm incomes, greater mobility or energy security at the household, local or regional level). We think of a

For the time being, we will only support the small scale, local use of biofuels for communities that decide for themselves - in full sovereignty and independence - that it makes sense to do so, for them and for whichever reason (improved farm incomes, greater mobility or energy security at the household, local or regional level). We think of a  The UN's FAO is

The UN's FAO is

Zimbabwe's Minster of Science and Technology Development, Dr Olivia Muchena,

Zimbabwe's Minster of Science and Technology Development, Dr Olivia Muchena,  Via

Via

Saturday, December 22, 2007

Choren announces site for world's first large-scale biomass-to-liquids plant

Choren managing director Tom Blades presented 2010 as the year in which construction would begin with fall 2009 being the period in which the €800 million investment should be finalized. The announcement was hailed by both federal, state and local politicians.

Schwedt came out as the best of 60 possible locations in Germany. Five further locations were drawn onto a map where future plants could be built. Which factors did Choren look at when selecting this site? The proximity to the oil refinery made Schwedt a site where synergies can be created concering the supply of heat and energy. In addition the Uckermark region has sufficient land potential for raw material production and an abundance of existing biomass residues that can be converted into synfuel (table, click to enlarge).

Moreover the presence of the Fachhochschule Eberswalde (University of Applied Sciences) in the area makes it possible to draw on advanced scientific research into bioenergy (on fast-rotation energy trees). The university already operates experimental fields in the proximity of Schwedt, on which it trials fast-growing woody energy crops for cellulosic biofuels.

Synthetic biofuels such as Choren's 'SunDiesel' are considered to be renewable fuels of the of the second generation. The ultra-clean fuels have an exceptionally low emissions profile. They are obtained from the gasification of a wide range of biomass feedstocks with the syngas liquefied via the Fischer-Tropsch process. Choren's technology, the 'Carbo-V Process' is a three-stage gasification process involving the following sub-processes: (1) low temperature gasification, (2) high temperature gasification and (3) endothermic entrained bed gasification.

During the first stage of the process, the biomass (with a water content of 15 – 20 %) is continually carbonized through partial oxidation (low temperature pyrolysis) with air or oxygen at temperatures between 400 and 500 °C, i.e. it is broken down into a gas containing tar (volatile parts) and solid carbon (char).

During the second stage of the process, the gas containing tar is post-oxidized hypostoichiometrically using air and/or oxygen in a combustion chamber operating above the melting point of the fuel’s ash to turn it into a hot gasification medium.

During the third stage of the process, the char is ground down into pulverized fuel and is blown into the hot gasification medium. The pulverized fuel and the gasification medium react endothermically in the gasification reactor and are converted into a raw synthesis gas. Once this has been treated in the appropriate manner, it can be used as a combustible gas for generating electricity, steam and heat or as a synthesis gas for producing SunDiesel.

The Carbo-V process has the following advantages over conventional biomass gasification:

- A wide range of feed materials can be used

- A high-quality gas with a tar content below minimum detection limits and a very low concentration of methane (<>

- Complete exploitation of the feed material used * Numerous fields of application (electricity, heat, cold, methanol, synthetic automotive fuels, waxes etc.) * Conversion efficiency for gasification (cold gas efficiency) > 80 %

- Electrical energy efficiency levels of up to 35 %

- Low emission levels

- The ash is converted into a solid bonded slag granulate suitable for building purposes

High-quality synthetic automotive fuels are obtained from the synthesis gas via Fischer-Tropsch (FT) synthesis. During this process, the reactive fractions of the synthesis gas (CO and H2) interact with a catalyst to form hydrocarbons. In order to maximize the output of synthetic biodiesel, the waxes formed during the FT synthesis process are further processed using hydrocracking techniques, a standard process that is used in the petrochemical sector to recycle waste substances at refineries.The synthetic biodiesel is an ultra-clean fuel which:

- has a high cetane number and therefore much better ignition performance than conventional diesel fuel,

- has no aromatics or sulfur and significantly reduces pollutants from exhaust emissions,

- can be used without any adjustment to existing infrastructure or engine systems,

- is largely CO2-neutral

The first BtL plant in Schwedt will bring about 700 jobs could develop, with 100 direct jobs at the facility with the remainder expected to develop in the forestry, transport, distribution and disposal sectors that will form around Choren's activities:Schwedt wants to become a leading bioenergy hub. In the vicinity of the oil refinery a set of new biofuel factories have already been established, in which biodiesel, bio-ethanol and wood pellets for heating purposes are produced.

The city of Choren's choice is located in one of former East Germany's most economically problematic regions. The Federal Government's Special Envoy for the New States ('Beauftragte der Bundesregierung für die neuen Länder', who is still tasked with integrating Eastern German 'Länder' into the more prosperous West), also the Federal Minister of Transport, Wolfgang Tiefensee, said the investment is 'a trailblazing project for the development of second generation biofuel production' and it proves that investment assistance for companies that want to establish themselves in East Germany remains a central component of the policy for the reconstruction of the regions economic structure.

The company is currently building the world’s industrial scale BTL plant (Beta plant) at its Freiberg site. From 2008, the plant is expected to produce approximately 15,000 metric tons of fuel a year. This would be sufficient to meet the annual requirements of some 15,000 cars.

But Choren's large plans for biomass-to-liquids and the first 200,000 ton plant to be located in Schwedt received a boost recently when both Volkswagen and Daimler - two of Germany's largest automakers - became minority shareolders in the company. These companies offer the key to ensure that a framework is created for the sustainable market introduction of the BtL fuels.

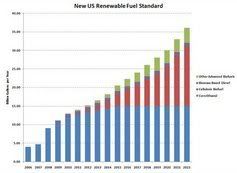

Last month the German Government also announced an ambitious new Biofuels Roadmap in which it massively increases the country's biofuels target, doubling it from 5% by 2010 to 10% by that year, and to 20% by 2020. This way it doubles the EU's biofuel targets (which require 10% of all fuels to be biofuels by 2020). The new plan is aimed at encouraging the development of next-generation biofuels such as synthetic biodiesel.

References:

Choren: Weltweit erste Großanlage für Biomasse-Kraftstoff soll in Schwedt entstehen - December 18, 2007.

Biopact: Volkswagen and Daimler become shareholders of BTL company CHOREN, aim to mass introduce ultra-clean synthetic biofuels - October 11, 2007

Biopact: Germany massively increases biofuels targets to kickstart next generation fuels: 10% in 2010, 20% in 2020 - November 22, 2007

Article continues

posted by Biopact team at 1:43 PM 0 comments links to this post