Engineers developing biomass-fired micro-CHP system for homes

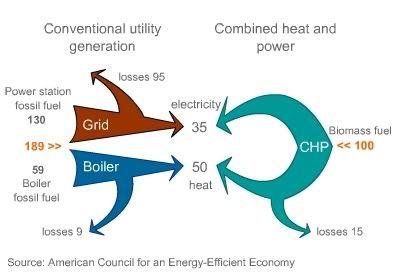

A new project at Nottingham University's School of the Built Environment aims to create the first small-scale biomass-fired combined heat and power (CHP) system, which is said to be ideal for use on farms and in other large domestic buildings. CHP systems are much more efficient (often 85% overall) than large-scale utility separate heat and power generation, but they have to be located close to thermal end users (domestic or industrial, integrated into district heating systems). They are ideal in a decentralised energy strategy, but require a strong logistical chain for distributing the biomass (pellets, chips, briquettes).

Even though micro-CHP systems are not commercially available, several companies are working on developing them. The UK's Carbon Trust is trying to speed up the introduction of the systems on the domestic and SME market. It is currently carrying out an assessment of the performance of this new equipment and will be providing a database of information from which to develop policies. It is actively working on a field trial and contracted 5 technology suppliers who have the opportunity to have their equipment tested in a range of 'live' customer applications.

Meanwhile, the School of the Built Environment's project aims to help prove the viability of small-scale CHP generation, according to Professor Saffa Riffat, one of the project's leaders and an expert in sustainable energy technologies and thermal engineering.

'At the moment there are a number of large-scale 100-200kW CHP generators but there are no domestic-sized ones,' said Riffat. 'This will be the first biomass-powered CHP on a small scale.'

The research is being developed at the school's Institute of Sustainable Energy. The first stage of the 18-month micro-CHP project, which began this month, is to look at ways of miniaturising the CHP components to enable smaller-scale biomass devices to be built. The project aims to develop a system that only produces up to 10kW, which is more than enough power for domestic use, according to Riffat.

Most CHP systems on the market are powered using fossil fuels, usually gas and oil, which does not sit well with the institute's sustainable energy ambitions. Also, most existing biomass generators are used only to produce electricity rather than as a combined CHP unit. The research aims to find a way of creating heat and power using a biomass-powered furnace. The institute plans to develop the steam Rankine turbine cycle, which is already the state of the art in biomass-powered energy production technology:

bioenergy :: biofuels :: energy :: sustainability :: combined heat-and-power :: CHP :: Rankine :: efficiency :: biomass ::

bioenergy :: biofuels :: energy :: sustainability :: combined heat-and-power :: CHP :: Rankine :: efficiency :: biomass :: The Rankine cycle uses a liquid that is pumped at a high pressure into a boiler, where it is heated until it becomes a vapour. This vapour is then expanded through a turbine, which provides electricity. Once it leaves the turbine it is quickly condensed back into a liquid then re-enters the pump so it can be re-pressurised and the cycle starts again.

This form of steam-driven Rankine power generation, although useful in large-scale energy production, is of less use in low-power systems because of its inherent low efficiency in energy generation and high capital costs. To make a system that only generates about 10kW, the efficiency would have to be greatly improved. To also provide heat generation as part of the same system Riffat and his team have modified the traditional cycle by using a refrigerant to power the turbine.

'We will have a biomass- powered furnace with a heat exchanger inside filled with a liquid refrigerant such as CO2 or pentane,' said Riffat. 'As a high-pressure vapour it will expand through a turbine at 500-600Cº and the turbine will produce electricity.' Up to this point, the Rankine Cycle remains unchanged.

However the use of the refrigerant adds a new element to the cycle: the production of heat. 'When the refrigerant is condensed and it moves back from vapour to liquid it gives up heat, which can then be utilised,' said Riffat.

The team has produced a miniature 2kW turbine and preliminary tests have revealed this modified design is more efficient and reliable than previous conventional systems. The next step is to couple one of these small turbines with a biomass boiler. Riffat hinted the research may encompass other innovations, including the elimination of the pumps in the cycle, that would make the system even more efficient in the future.

He said there is a large and growing market for a system that could reuse household waste and other biomass materials to produce small-scale localised power and heat generation, particularly in farms. 'If you are using large-scale CHP you have to get a group of houses together where everybody wants to be involved, which isn't always easy,' he said.

The team aims to commercialise the system soon although it does not yet have any industrial partners. The first prototype could be ready in six months, claimed Riffat.

More information:

GODEFROY,J., BOUKHANOUF,R. and RIFFAT,S., 2007. Design and mathematical modelling of small-scale CHP and cooling system. Applied Thermal Engineering, 27(1), 68-77.

Article continues

-------------------

-------------------

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

Sunday, November 19, 2006

German biogas association: green gas can replace 50 percent of Germany's Russian gas imports

The advisor in question, Ulrich Schmack, is the co-founder of the world's largest biogas plant manufacturer and operator, Schmack Biogas AG. This publicly traded company has meanwhile put its money where its mouth is, and has started feeding highly purified biogas from biomass crops into the national natural gas grid. Unlike the more than 2300 medium-scale biogas plants in Germany that are already delivering electricity locally to farmers and small towns, Schmack's approach is that of an industrial-scale energy provider. In order to scale-up and to get a stake in the distribution sector, the company recently created a joint-venture with Erdgas Südbayern Wärme GmbH, a natural gas energy company that delivers electricity and heat to households.

Schmack's remark that dedicated biomass crops can produce over 40 billion cubic meters (1.4 trillion cubic feet) of biogas per year in 2030, was nuanced by the German Biogas Association (Fachverband Biogas), which made a statement at the closing of BioEnergy Europe 2006, a major industry event held in Hannover last week. The Association said that in 2006, investments in Germany's biogas sector will surpass 1 billion euros. This makes it the fastest growing renewable energy sector in the country. Some 10,000 people have found employment in this sector (planning, construction, manufacture and operation of biogas plants; producing feedstocks). By the end of the year, Germany will have some 3,500 medium-scale plants online. In 2006, some five billion KWh of electricity will be generated from biogas in the country, and the amount will double once again in the first half of next year. The Association concludes that at this pace and with current technologies, the industry will tap a potential that can replace half of all Russian gas imports 'in the near future' [entry ends here].

Article continues

posted by Biopact team at 6:12 PM 0 comments links to this post