Researchers develop model to show impacts of government policy, oil prices on ethanol costs

The recent boom in production of ethanol from corn grain has tightly linked America's agriculture and energy sectors in an unprecedented fashion. Purdue University researchers developed a model, based on a range of possible oil prices, that predicts impacts of federal economic policies on future consumer and government costs, ethanol production and many other aspects of the two sectors.

The recent boom in production of ethanol from corn grain has tightly linked America's agriculture and energy sectors in an unprecedented fashion. Purdue University researchers developed a model, based on a range of possible oil prices, that predicts impacts of federal economic policies on future consumer and government costs, ethanol production and many other aspects of the two sectors.Wally Tyner, a Purdue professor of agricultural economics, presented his results at the annual meeting of the American Association for the Advancement of Science (AAAS) in Boston. "The U.S. is living through a revolution in American agriculture," he said.

Tyner said the prices of corn and crude oil, which prior to 2007 fluctuated almost independent of one another, have become more closely linked thanks to the use of massive quantities of corn to make ethanol. This year that's about one-third of the total national harvest. Now, oil and ethanol are both big players in agriculture. In the future, they will march together, and their march will depend upon government policies.

In the past, when you asked people what policies were important for agriculture, they would talk about target prices, loan rates and efficient payments. For now all of these are gone, inoperative with high corn prices. It's a whole new paradigm. - Wally Tyner, professor of Agricultural Economics, Purdue UniveristyFour policy options

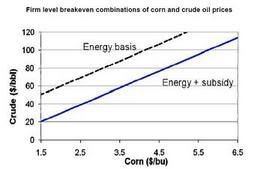

Tyner analyzed how ethanol fares under different policy options and oil price levels, and who carries the burden of any "externalities" (hidden costs, subsidies). The model includes four of these options - (1) the current 51-cent fixed subsidy, (2) a variable subsidy, (3) no subsidy and (3) a renewable fuel standard (RFS) - at oil prices ranging from $40 per barrel to $120 per barrel. (Figure shows profitability of a typical ethanol producer with and without the 51 cents ethanol subsidy for different combinations of corn-crude prices, click to enlarge).

Regardless of the policy, results become similar at high crude oil prices where the market dominates; under several scenarios, ethanol does not need subsidies. At low oil prices, however, government policies have huge effects, and all the results are enormously different. The policy choices made will therefor be critical.

The model shows that the fixed 51-cent per gallon subsidy paid to ethanol producers will become increasingly expensive for the federal government as oil prices - and levels of ethanol production - rise.

One alternative policy option, a variable subsidy that changes relative to crude oil prices, would only be paid by the government when crude oil sinks to less than $70 per barrel. When oil prices are higher, ethanol production should be profitable and would not need to be subsidized:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: corn :: subsidy :: oil price :: agricultural economics ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: corn :: subsidy :: oil price :: agricultural economics :: The renewable fuel standard contained in the 2007 Energy Act mandates that energy companies purchase 35 billion gallons of ethanol by 2022, with a maximum of 15 billion gallons coming from corn.

With oil at $40 per barrel, for example, ethanol production is not profitable without a subsidy or higher fuel costs. With a fixed or variable subsidy in effect at this oil price, the government spends $5 billion per year to subsidize ethanol production. Ethanol is considerably more expensive than fuel made from petroleum in this scenario, but with the renewable fuel standard in effect, fuel companies are required to buy 15 billion gallons of corn ethanol per year. At $40 crude, the standard would cost consumers an extra $12 billion per year at the pump.

Subsidies are paid out of taxpayer dollars by the federal government, while the renewable fuel standard costs consumers at the pump.

Therefore, the standard does imply costs at low oil prices, when buying ethanol would otherwise be uneconomical. His model calculates the hidden cost of the standard, which tacks on an extra $1.05 per gallon when oil is $40. In such a situation, in other words, ethanol costs $1.05 more per gallon to produce from corn grain than gasoline costs to produce from crude oil, and the consumer indirectly makes up the difference.

If oil surpasses $100 per barrel, however, the renewable fuel standard costs consumers little or nothing extra. That's because at this price, ethanol production costs are very close to gasoline production costs.

With today's oil greater than $90 per barrel, $40 oil might seem unlikely. In the last two decades, however, oil has only surpassed $40 since 2004 and cost an average of only $20 per barrel for most of that period. Reduced oil demand, global recession or any number of factors could cause oil prices to sink to $40 once again.

Corn use under different options

One of the most dramatic aspects of the ethanol "revolution" is a ballooning percentage of corn crops being made into ethanol, which prior to 2004 had always been lower than 10 percent. This year, for the first time, ethanol replaced exports to become the second largest use of the grain behind that of domestic animal feed. With a fixed subsidy in effect, the amount of corn used for ethanol increases from 12 percent for $40 oil to 52 percent for $120 oil, the model predicts. With the renewable fuel standard, the ethanol share is quite stable, ranging from 44 percent for $40 oil to 47 percent for $120 oil.

With the fixed subsidy in effect, ethanol production ranges from 3.3 billion gallons a year at $40 oil to 17.6 billion gallons with $120 oil. The variable and no-subsidy policies yield 6.5 billion gallons at $80 oil and 12.7 billion for $120 oil.

The renewable fuel standard seems to guarantee ethanol's future, but further decisions need to be made to develop a "bridge policy" to spur investment in cellulosic ethanol. Cellulosic ethanol - derived from grasses, waste materials and agricultural residues - has potential to be more efficient than ethanol from corn grain.

Cellulose, a complex carbohydrate present in all plant tissues, is more abundant in plants than starch. The renewable fuel standard mandates that fuel companies purchase 20 billion gallons of cellulosic ethanol by 2022. But exactly how this will be achieved remains to be seen, and future policies need to take into account the newly emerged oil-corn link, he said.

Predictions from Tyner's model point to a time in the future, roughly 2020, when gasoline and ethanol pricing follow a more stable long-run pattern.

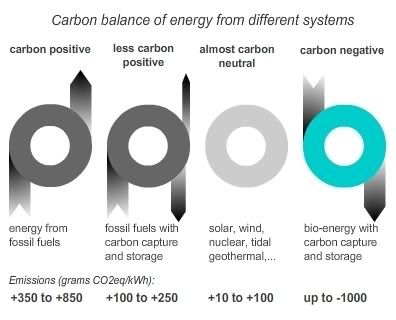

Ethanol has potential to reduce America's dependence on foreign petroleum and reduce greenhouse gas emissions, which are goals that cannot be fixed by the market alone. Economists call these "externalities" and suggest fixing these market failures through taxes, subsidies or some form of regulation. In this work, Tyner has focused on subsidies or regulations because taxes have not generally been used in this situation in the United States, he said.

Tyner's paper will be published this year in the Review of Agricultural Economics, co-authored by Purdue researcher Farzad Taheripour. The authors evaluated two future scenarios: one assumes that fuel standards will increase sufficiently to reduce oil demand while the other assumes global oil demand will grow faster than oil supply, resulting in what economists call a demand shock.

References:

Wallace E. Tyner and Farzad Taheripour, "Policy Options for Integrated Energy and Agricultural Markets" [*.pdf], Purdue University - Paper Presented at the Transition to a Bio-Economy: Integration of Agricultural and Energy Systems conference on February 12-13, 2008 at the Westin Atlanta Airport planned by the Farm Foundation.

Purdue Univeristy: Agricultural Economics Papers.

Article continues

--------------

--------------

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

A growing number of remote sensing service companies is finding opportunities in the emerging bioenergy sector, by providing detailed data about the availability of biomass in a given region and the feasibility of harvesting it for commercial use. Similarly, several governments and international organisations are drawing on earth observation data that drive GIS-tools which allow policy makers and investors to assess biofuels potential, make investment and management decisions and allow for estimates of impacts on local economies, ecosystems and populations.

A growing number of remote sensing service companies is finding opportunities in the emerging bioenergy sector, by providing detailed data about the availability of biomass in a given region and the feasibility of harvesting it for commercial use. Similarly, several governments and international organisations are drawing on earth observation data that drive GIS-tools which allow policy makers and investors to assess biofuels potential, make investment and management decisions and allow for estimates of impacts on local economies, ecosystems and populations.

MIT physicists have taken a

MIT physicists have taken a  A group of environmentalists has

A group of environmentalists has

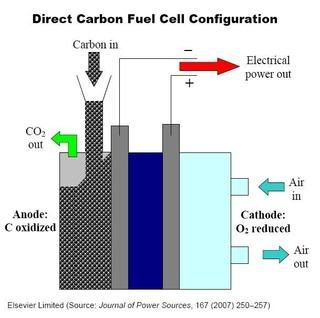

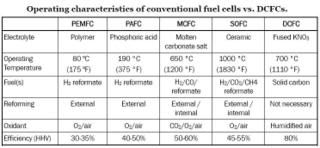

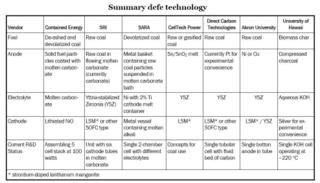

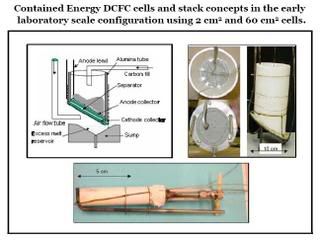

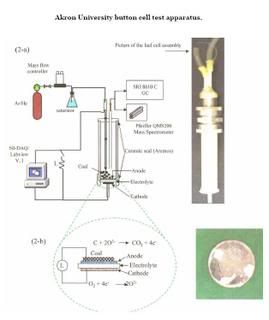

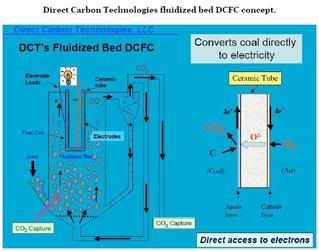

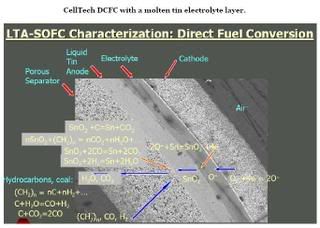

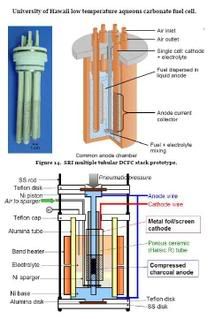

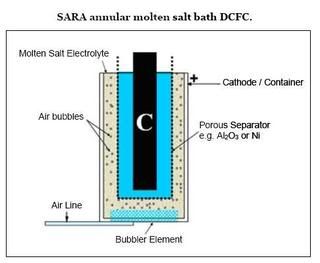

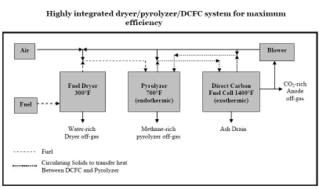

DCFC's can use a large number of carbon-rich fuels, but organic waste and biomass are at the center of the attention because they are renewable and clean, but also because they can be turned into the purest carbon fuel. The overall process of producing electricity in a DCFC from biomass gains efficiency by its simplicity. It involves only two steps: (1) drying (and/or pyrolysis, or hydrothermal carbonization) to obtain char, and (2) feeding the resulting fuel directly to the DCFC. Drying and/or pyrolysis or conversion into char via hydrothermal carbonization is required to create a carbon-rich particulate solid that can be fed to the DCFC fuel cell to produce power:

DCFC's can use a large number of carbon-rich fuels, but organic waste and biomass are at the center of the attention because they are renewable and clean, but also because they can be turned into the purest carbon fuel. The overall process of producing electricity in a DCFC from biomass gains efficiency by its simplicity. It involves only two steps: (1) drying (and/or pyrolysis, or hydrothermal carbonization) to obtain char, and (2) feeding the resulting fuel directly to the DCFC. Drying and/or pyrolysis or conversion into char via hydrothermal carbonization is required to create a carbon-rich particulate solid that can be fed to the DCFC fuel cell to produce power:

Georgia Power and Greenway Renewable Power LLC, an affiliate of bioenergy company Rollcast Energy Inc.,

Georgia Power and Greenway Renewable Power LLC, an affiliate of bioenergy company Rollcast Energy Inc.,

Saturday, February 16, 2008

Branson sees future in African biofuels; regrets investments in U.S. corn ethanol

Billionaire biofuel investor Richard Branson has admitted that his investments in U.S. corn ethanol may have been a mistake, both financially and environmentally. The fuel is not very efficient, results in food price increases and cannot compete with far more efficient biofuels made in the South, unless it is heavily subsidized.

Instead, Branson is now looking at Africa, citing the example of a country like Mozambique, where sugarcane can yield up to 7 times more ethanol per acre.

Biopact is pleased to see an investor like Branson looking at the potential of Africa, instead of sticking to inefficient corn ethanol. Bioenergy and agricultural experts have repeatedly said the continent is waiting for courageous entrepreneurs to help kickstart the Green Revolution there.

Africa is the continent with the largest sustainable bioenergy potential. It can produce more bioenergy than all the oil currently consumed world-wide, while providing enough food, fiber and forest products to its growing populations, and without negative impacts on the environment. In fact, bioenergy can help stimulate food production and conservation, by making African agriculture more efficient and productive.

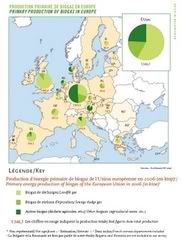

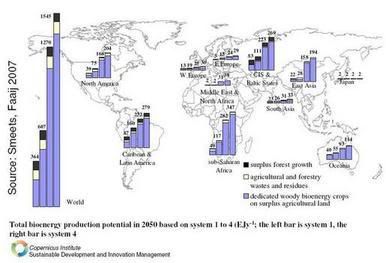

Experts of the IEA Bioenergy Task 40, drawing on a model now also officially used by the FAO, have shown that the region can produce around 350 Exajoules of bioenergy by 2050, if modern agricultural techniques are utilized (see map, click to enlarge; and see previous post). That is around 50 percent more than all oil currently consumed on the planet. Next-generation biofuels produced in Africa can be highly sustainable and reduce emissions substantially (e.g. when based on polycultures of grasses, high yielding woody crops like eucalyptus, or even on first generation crops like sugarcane or sweet sorghum).

On the basis of these findings, Biopact has been trying to convince investors, non-profits, civil society and governments that we can create a win-win situation between the West and the South, by allowing farmers in Africa and Latin America to bring their efficient biofuels on the market (first their own, then global markets). This could help rural development in the poorest regions of the planet, and would be far more efficient than relying on low yielding biofuel production systems like U.S. corn ethanol.

However, this win-win idea requires major policy initiatives, trade and subsidy reform, and investments in modern agriculture and infrastructures in Africa. Perhaps Richard Branson could help kickstart this transformation?

Video: BBC News, February 12 [entry ends here].

Article continues

posted by Biopact team at 4:08 PM 1 comments links to this post