The Seven Commandments of Mexican biofuels: from social justice to sustainability

In a very interesting essay Ricardo Cantú of Mexico's School of Public and Political Administration at Monterey's Technological University explores how one might go about creating a sustainable ethanol economy that simultaneously serves the interests of social justice, the environment, and energy security, in the context of Mexico. A project much like that of the Biopact, focused on Sub-Saharan Africa.

In a very interesting essay Ricardo Cantú of Mexico's School of Public and Political Administration at Monterey's Technological University explores how one might go about creating a sustainable ethanol economy that simultaneously serves the interests of social justice, the environment, and energy security, in the context of Mexico. A project much like that of the Biopact, focused on Sub-Saharan Africa.The overriding goal emerging from Cantú's excellent paper titled "Ethanolomics: The Think-About's of the Mexican Ethanol Project" [*.pdf] is to devise a strategy for improving the living standards of the rural poor in Mexico via an invigoration of the agricultural economy, boosting energy security for the population at large while limiting the catastrophic effects of high oil prices on the poor, and contributing to the fight against climate change by producing fuels that effectively reduce carbon emissions.

In theory, biofuels "could potentially [...] solve all of the above problems" writes Cantú, an argument voiced by many biofuel proponents in the Global South (and partially by organisations like the FAO, the WorldWatch Institute and the IEA). Plant based alternatives to oil could:

diminish the global ecological harm that the fossil fuels are making; lessen the economical dependence of some countries with the global markets and foreign policies [...]; be a renewable energy source, because it would use biomass inputs; and power up rural economical dynamism.But this is theory. The same theory set out in our 'Biofuels Manifesto'. In reality, biofuels can go two ways: either perpetuating social injustices, concentrating power in an ever smaller number of hands, and damaging the environment, or they can become an engine for poverty alleviation, rural revival, a healthier environment, reduce hunger and bring global social justice. In order to make sure biofuels take the latter path, Cantú provides a set of ground rules. It won't be easy to follow them, but it is not impossible either. The guidelines are:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: climate change :: poverty alleviation :: rural development :: energy security :: Mexico ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: climate change :: poverty alleviation :: rural development :: energy security :: Mexico :: - Over the whole chain, the use of biomass should produce fewer emissions of greenhouse gases net than on average with fossil fuel.

- Production of biomass for energy must not endanger the food supply and other local applications (such as for medicines or building materials).

- Biomass production must not affect protected or vulnerable biodiversity and will, where possible, have to strengthen biodiversity.

- In the production and processing of biomass, the quality of soil, surface and ground water and air must be retained or even increased.

- The production of biomass must contribute towards local prosperity.

- The production of biomass must contribute towards the social well being of the employees and the local population.

- The overall ethanol production costs should be cheaper and more accessible than that of the fossil fuels, or at least the same level, excluding all the subsidies or tax benefits to the producers or distributors.

Cantú stresses that a key requirement of a biofuel economy in Mexico is that the farmers capture the rewards of their production. In other words, one wants to avoid a situation in which farmers sell their sugar cane or maize or sorghum at rock-bottom prices to middlemen who then grab all the upstream profits. Cantú envisions farmer cooperatives setting up their own ethanol mills, and dealing directly with distributors.

Such a model is not uncommon in the U.S. and in Europe, and there's no reason, in principle, it couldn't work in Mexico or in other developing countries, says Leonard. But it would require strong government leadership and the sharp eye of civil society organisations to check whether policies are enacted.

Indeed, to achieve all the goals outlined above would require a tightly regulated market with significant government intervention: in other words, a direct repudiation of the kind of Washington Consensus policies of deregulation and privatization that the West has been pushing on Latin America and elsewhere for decades.

References:

Ricardo Cantú, "Ethanolomics: The Think-About’s of the Mexican Ethanol Project" [*.pdf], Cátedra de Integración Económica y Desarrollo Social, Escuela de Graduados en Administración Pública y Politica Pública, Tecnológico de Monterrey, Working Paper No. 2007-3.

Salon: The Seven Commandments of Mexican ethanol - September 28, 2007.

Biopact: Worldwatch Institute chief: biofuels could end global malnourishment - August 23, 2007

Biopact: FAO chief calls for a 'Biopact' between the North and the South - August 15, 2007

Biopact: IEA report: bioenergy can meet 20 to 50% of world's future energy demand - September 12, 2007

Biopact: High oil prices disastrous for developing countries - September 12, 2007

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

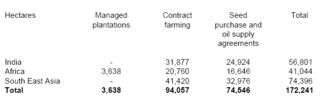

The palm oil industry is a corner stone of Malaysia's economy, generating export revenues only surpassed by oil and gas. It has become politically incorrect to say this, but over the past decades the sector has brought unprecedented wealth to hundreds of thousands of small farmers. Small holders retain a 41% share of the hectarage in the sector. The incidence of small holder poverty has dropped from 30% in the 1970s to nearly zero today, a stronger reduction than observed in any other agricultural segment. According to an

The palm oil industry is a corner stone of Malaysia's economy, generating export revenues only surpassed by oil and gas. It has become politically incorrect to say this, but over the past decades the sector has brought unprecedented wealth to hundreds of thousands of small farmers. Small holders retain a 41% share of the hectarage in the sector. The incidence of small holder poverty has dropped from 30% in the 1970s to nearly zero today, a stronger reduction than observed in any other agricultural segment. According to an

RWE Power, BASF and The Linde Group today

RWE Power, BASF and The Linde Group today

The idea behind the experiment is to reduce the capital area’s emission levels from public transportation. The nitrogen oxide and particle emissions of biodiesel are lower than those of regular diesel.

The idea behind the experiment is to reduce the capital area’s emission levels from public transportation. The nitrogen oxide and particle emissions of biodiesel are lower than those of regular diesel.

With the urgent need to reduce greenhouse gas emissions and to cut our reliance on increasingly costly and non-renewable oil, the need for action in plant sciences arises to obtain an economically viable and sustainable production of renewable biofuels, green chemicals and biomaterials. While other countries already attribute significant research money to this field (e.g. more than $800 million in recent projects on biofuels in the US, $3 billion for the bioeconomy in Brazil), Europe still lacks concerted action. The EU's renewable energy directive, calling for 20% biofuels and renewables by 2020, is ambitious, but research support is insufficient to achieve these goals. In response, the

With the urgent need to reduce greenhouse gas emissions and to cut our reliance on increasingly costly and non-renewable oil, the need for action in plant sciences arises to obtain an economically viable and sustainable production of renewable biofuels, green chemicals and biomaterials. While other countries already attribute significant research money to this field (e.g. more than $800 million in recent projects on biofuels in the US, $3 billion for the bioeconomy in Brazil), Europe still lacks concerted action. The EU's renewable energy directive, calling for 20% biofuels and renewables by 2020, is ambitious, but research support is insufficient to achieve these goals. In response, the  High oil prices have negative impacts on a range of social and economic activities, especially in the developing world. The least developed countries are energy intensive and consequently spend much more on oil as a percentage of GDP than highly developed countries. According to the African Union, Sub-Saharan African countries poured between 10 and 15% of their GDP into oil imports in 2006, whereas OECD countries spent only 1.5-3%. In oil importing poor countries, each price increase can be felt immediately throughout the economy on both the macro- and micro-economic front, with poor classes suffering most (

High oil prices have negative impacts on a range of social and economic activities, especially in the developing world. The least developed countries are energy intensive and consequently spend much more on oil as a percentage of GDP than highly developed countries. According to the African Union, Sub-Saharan African countries poured between 10 and 15% of their GDP into oil imports in 2006, whereas OECD countries spent only 1.5-3%. In oil importing poor countries, each price increase can be felt immediately throughout the economy on both the macro- and micro-economic front, with poor classes suffering most ( Belgian-Dutch Fortis Bank has bought carbon credits equivalent to 808,405 tonnes of CO2 which were offered in an auction by the São Paulo Municipal Government on the Brazilian Mercantile & Futures Exchange (BM&F). This was the world’s first Certified Emission Reductions (CERs) spot market auction managed and promoted by a regulated exchange, representing an important initial step in the organization and development of a global market for environmental certificates. The

Belgian-Dutch Fortis Bank has bought carbon credits equivalent to 808,405 tonnes of CO2 which were offered in an auction by the São Paulo Municipal Government on the Brazilian Mercantile & Futures Exchange (BM&F). This was the world’s first Certified Emission Reductions (CERs) spot market auction managed and promoted by a regulated exchange, representing an important initial step in the organization and development of a global market for environmental certificates. The  ConocoPhillips and Archer Daniels Midland Company today

ConocoPhillips and Archer Daniels Midland Company today

In its

In its

In September, the first installation in The Netherlands which retrieves biogas from the sewage treatment process for domestic and transport use officially

In September, the first installation in The Netherlands which retrieves biogas from the sewage treatment process for domestic and transport use officially

The European Union's set-aside scheme, whereby farmers receive subsidies to leave 10% of their land unused to avoid surplus production, has been suspended for 2008. The European Parliament (EP)

The European Union's set-aside scheme, whereby farmers receive subsidies to leave 10% of their land unused to avoid surplus production, has been suspended for 2008. The European Parliament (EP)  Israeli biomass energy start-up

Israeli biomass energy start-up

It was found that 488 households preferred biogas plants while 186 voted for vermi-compost units. Interestingly, 19 per cent of the respondents said that they did not want assistance for installation of biogas or vermi-compost units, said Radha Thevannoor, project co-ordinator and director of the SCMS School of Technology and Management.

It was found that 488 households preferred biogas plants while 186 voted for vermi-compost units. Interestingly, 19 per cent of the respondents said that they did not want assistance for installation of biogas or vermi-compost units, said Radha Thevannoor, project co-ordinator and director of the SCMS School of Technology and Management.

Three leading palm oil market analysts each offer a substantially different medium term outlook for the commodity. These differences are the result of uncertainties about biofuel subsidies in the US, demand in Asia, the development of other vegetable oil markets and the outlook for crude oil.

Three leading palm oil market analysts each offer a substantially different medium term outlook for the commodity. These differences are the result of uncertainties about biofuel subsidies in the US, demand in Asia, the development of other vegetable oil markets and the outlook for crude oil. At last, a mainstream publication has begun to understand the logic behind the Biopact. Writing for the

At last, a mainstream publication has begun to understand the logic behind the Biopact. Writing for the

When urbanites in Thailand hear about 'mansampalang', 'manioc' or 'tapioca' they usually think of poor Isaan farmers who are unable to grow anything better on their parched sandy soil. But Reinhardt Howeler, scientist at the Cassava Office for Asia of the

When urbanites in Thailand hear about 'mansampalang', 'manioc' or 'tapioca' they usually think of poor Isaan farmers who are unable to grow anything better on their parched sandy soil. But Reinhardt Howeler, scientist at the Cassava Office for Asia of the  Earlier this year, the city of Växjö in southern Sweden

Earlier this year, the city of Växjö in southern Sweden

In December 2006, the French Ministry for the Environment and Sustainable Development launched the 'Biomasse 2' plan, which aims to build highly efficient biomass power plants with a combined capacity of 300MW. The ministry now

In December 2006, the French Ministry for the Environment and Sustainable Development launched the 'Biomasse 2' plan, which aims to build highly efficient biomass power plants with a combined capacity of 300MW. The ministry now

Saturday, September 29, 2007

Research finds recovery from acid rain much slower than expected

Over the last 20 years, serious action has been taken across Europe to clean up acid pollutants from power generation and industry, which was widely expected to bring recovery. However, new research led by Cardiff University's School of Biosciences shows that the expected improvements in rivers are far short of expectations.

An example from India illustrates the dramatic effects of acid rain on agricultural productivity: researchers there found that wheat growing near a coal-fired power plant where SO2 deposition was almost five times greater than the critical load (the amount the soil can safely absorb without harm) suffered a 49 percent reduction in yield compared with wheat growing 22 kilometers away.

Damage could be largely avoided if modern pollution control technologies, such as flue-scrubbers, are widely adopted and if low-sulfur fuels are used. In this context, bioenergy and biofuels offer a major alternative to coal and oil. Co-firing low-sulfur biomass in power plants combined with a transition to 100% biomass power plants and biofuels in transportation can drastically reduce both SOx and NOx emissions.

From the Cardiff University scientists we learn that these efforts are urgent, because ecosystem recovery from acid rain takes much longer than expected. Recent studies in Galloway, the Scottish Highlands and Wales reveal that many streams are still highly acidified, decades after the first pollution control measures came into effect. Biological recovery has been particularly poor.

Key findings from the projects, carried out by combined teams from Cardiff University, the Centre for Ecology & Hydrology and National Museum Wales, include:

- Acidity in Welsh headwaters is declining, but only slowly

- More than two thirds of all streams sampled were acid enough during high flow to cause biological damage, with metals at toxic concentrations

- Sulphur pollution from man-made sources is still an important cause of acid episodes, particularly in Wales

- Sensitive insects survive conditions in the most acid streams for only a few days

- Headwater acidification is still a significant problem for important salmon fisheries, and Special Areas of Conservation such as the Welsh River Wye.

Professor Steve Ormerod of the School of Biosciences, a leading researcher into the biological effects of acid rain for more than 20 years, said: "Organisms and ecosystems are the best indicators of recovery from pollution, so these results will alarm anyone interested in the well-being of our rivers. We need to understand the factors responsible for such delayed recovery, particularly since climate change is likely to make the acidification problem even worse."Dr Chris Evans, an acid-rain specialist from the Centre for Ecology & Hydrology in Bangor, added "pollution reductions are slowly improving in upland waters, but there is a long way to go. The large biological effects of acid episodes shown by this work mean that it is vital to continue monitoring these ecosystems if we are to protect them in future."

The research contrasts with other recent studies which showed some encouraging early signs and will come as disappointing news to those who thought the acid rain problem was solved.

Graph credit: World Resources Institute.

References:

Eurekalert: Recovery from acid rain 'much slower than expected' - September 28, 2007.

World Resources Institute: Acid Rain: Downpour in Asia.

Article continues

posted by Biopact team at 5:30 PM 0 comments links to this post