Brazil's CTC releases third generation of sugarcane varieties that yield up to 38 percent more profit

Brazil's universities and scientific organisations are world leaders in researching, developing and breeding sugarcane varieties. It was Brazil that first sequenced the energy crop's genome, and the country plants more of the genus than any other country. It also houses the world's largest library of genetic information on different sugarcane species. Now six new varieties have been developed [*Portuguese] by the Centro de Tecnologia Canavieira (CTC), which yield around 20% more biomass and contain higher levels of saccharose - the disaccharide that ends up as table sugar and ethanol. This results in increased profits per hectare of between 12.5 and 38 percent.

Brazil's universities and scientific organisations are world leaders in researching, developing and breeding sugarcane varieties. It was Brazil that first sequenced the energy crop's genome, and the country plants more of the genus than any other country. It also houses the world's largest library of genetic information on different sugarcane species. Now six new varieties have been developed [*Portuguese] by the Centro de Tecnologia Canavieira (CTC), which yield around 20% more biomass and contain higher levels of saccharose - the disaccharide that ends up as table sugar and ethanol. This results in increased profits per hectare of between 12.5 and 38 percent.Breeding a sugarcane variety merely for increased biomass productivity does not suffice, says Marcos Casagrande, coordinator of plant breeding at the CTC. What use is a 20 percent increase in biomass when the variety has low levels of saccharose, cannot be harvested mechanically or is susceptible to diseases? To make a new variety worthwile for the production of sugar, bioenergy and ethanol, all of these factors must be targeted and combined in such a way that the new crop improves on all of them. A tall order indeed.

But the CTC delivered when it launched its third generation of sugarcane varieties for producers of different regions in the country's Center-South. The new varieties are called CTC10 through to CTC15, yielding more biomass with a higher saccharose yield.

The CTC's new varieties of the grassy crop are suitable for a specific region of the large country, known for its varied regional climatic conditions, its different soils and its different planting and harvesting seasons. The key to increased productivity is to develop varieties with the precise genetic material to match best with a specific region, and to plant them in the correct place. If this condition is not met, basic actions like correct fertilisation and cutting the cane at the optimal moment of maturation are in vain.

But what matters most, says Tadeu Andrade, director of Research & Development at the CTC, is the question as to whether a new variety will net more profits. And indeed, CTC 10 to CTC 15, bring in considerable more profits because the 'liquid margin' (margem líquida de contribuição) is much higher than current varieties.

According to Rubens Braga Júnio, statistician at the CTC, the 'liquid margin' represents the net profits generated by a given amount of sugar-rich juice harvested per hectare that can be processed into finished products like ethanol or sugar, after all costs for farm inputs (preparation, plantation, treatment, harvest and transport of the cane to the processing plant) and processing inputs have been subtracted. The liquid margin is averaged over a five-year period, the ideal life-cycle of sugarcane, which is a semi-perennial.

For CTC10 to CTC15 the liquid margin is between 12.5 to 37.85 percent higher than the conventional RB and SP varities that were developed by Brazilian universities and the Institute Agronômico de Campinas (IAC), which cover half of the sugarcane planted in the country:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: sugar :: genetics :: plant breeding :: sugarcane :: Brazil ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: sugar :: genetics :: plant breeding :: sugarcane :: Brazil :: An example, CTC11 yields an average of 8.43 percent more biomass per hectare compared to existing varieties, but the liquid margin is R$539 (€210/$308) or 37.85 percent higher than the average. This is due because of a better performance on all parameters that count in sugar and ethanol production: higher saccharose content, better harvesteability and processing and improved tolerance to diseases, reducing the risk of losing harvests - a factor against which producers hedge, which costs money.

For the CTC, the success can be measured by the growing number of distributers and producers that join its program and offer its new varieties to planters. In 2004 the Center had 73 associates. Today the number has reached 163, which results in the CTC's sugarcane plants covering 54.4 percent of the total harvested in Brazil.

The Centro de Tecnologia Canavieira is the leading sugarcane research institute in Brazil, developing new varieties with improved processing efficiency and yield. It is further involved in phytosanitary research, biotechnology, agronomy, agricultural and industrial mechanisation as well as sugar, bioenergy and biofuel production itself.

The CTC is a non-profit whose aim is to disseminate knowledge, best practises and inputs to the sugarcane sector in Brazil.

References:

EthanolBrasil: Novas variedades de cana rendem 38% mais - November 8, 2007.

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Some biofuel skeptics have said that the production of the fuels requires large inputs of fossil fuels, and that rising energy prices will therefor severely impact profitability. Others have said biofuel production can just as well become entirely green, when fossil inputs are replaced by renewables, some of which have become competitive with fossil energy. In Brazil this is already being done routinely by utilizing waste biomass as the primary energy source for powering the ethanol factories.

Some biofuel skeptics have said that the production of the fuels requires large inputs of fossil fuels, and that rising energy prices will therefor severely impact profitability. Others have said biofuel production can just as well become entirely green, when fossil inputs are replaced by renewables, some of which have become competitive with fossil energy. In Brazil this is already being done routinely by utilizing waste biomass as the primary energy source for powering the ethanol factories.

German bioethanol producer Verbio says a combination of cheap imports from Brazil and high grain prices means commercial production of bioethanol in Germany is hardly possible. In a sense, this is good news, because it clearly demonstrates the need for and benefits of a 'Biopact' - a win-win strategy that allows developing countries to make use of their comparative advantages at producing efficient, sustainable and affordable biofuels, and European citizens to import them instead of making their own highly unsustainable and inefficient biofuels from grains, which drives up food prices.

German bioethanol producer Verbio says a combination of cheap imports from Brazil and high grain prices means commercial production of bioethanol in Germany is hardly possible. In a sense, this is good news, because it clearly demonstrates the need for and benefits of a 'Biopact' - a win-win strategy that allows developing countries to make use of their comparative advantages at producing efficient, sustainable and affordable biofuels, and European citizens to import them instead of making their own highly unsustainable and inefficient biofuels from grains, which drives up food prices.

In September, Dow Polyurethanes, a business group of The Dow Chemical Company, successfully

In September, Dow Polyurethanes, a business group of The Dow Chemical Company, successfully

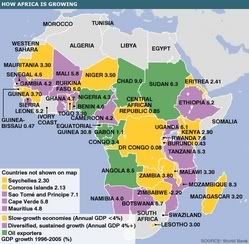

Greater integration with the global economy especially through export trade, are characteristics common to all African countries that have recorded sustained growth. These according to the ADI largely explain the aggregate efficiency levels and investment volumes – comparable to India and Vietnam – recorded by these countries. Overall investments in Africa increased from 16.8% of GDP to 19.5% of GDP between 2000 and 2006.

Greater integration with the global economy especially through export trade, are characteristics common to all African countries that have recorded sustained growth. These according to the ADI largely explain the aggregate efficiency levels and investment volumes – comparable to India and Vietnam – recorded by these countries. Overall investments in Africa increased from 16.8% of GDP to 19.5% of GDP between 2000 and 2006. Canada's Inniskillin Wines and StormFisher Biogas

Canada's Inniskillin Wines and StormFisher Biogas

The Global Bioenergy Partnership (GBEP) which

The Global Bioenergy Partnership (GBEP) which  Sembcorp Industries (Sembcorp) has officially

Sembcorp Industries (Sembcorp) has officially

Tel Aviv University (TAU) Professor Hudi Benayahu, a marine biologist in the Department of Zoology, has

Tel Aviv University (TAU) Professor Hudi Benayahu, a marine biologist in the Department of Zoology, has

The Charcoalab now takes these experiments to the classroom in a fun and hands on way. The initiative was recently launched by Christelle Braun, Phd student in bioenergy at the Technical University of Dresden, who thought terra preta deserved attention from a wider audience. Young people can test the effectiveness of the technique with a kit that contains samples of charcoal, a set of pots with soil and seeds, and instructions on how to conduct trials. Like real agronomists, the 'certified charcoal testers', set up experiments and compare plant growth in charcoal-amended soils versus unaltered, ordinary soils.

The Charcoalab now takes these experiments to the classroom in a fun and hands on way. The initiative was recently launched by Christelle Braun, Phd student in bioenergy at the Technical University of Dresden, who thought terra preta deserved attention from a wider audience. Young people can test the effectiveness of the technique with a kit that contains samples of charcoal, a set of pots with soil and seeds, and instructions on how to conduct trials. Like real agronomists, the 'certified charcoal testers', set up experiments and compare plant growth in charcoal-amended soils versus unaltered, ordinary soils.

Saturday, November 17, 2007

IPCC scientists call on bioenergy and biofuels to help combat global warming

The UN's climate panel states that climate change is 'unequivocal', man made and - this is new - may bring 'abrupt and irreversible' impacts. This means that the window to mitigate and adapt is closing quickly. It also implies that strategies that were specifically designed to deal with the eventuality of 'abrupt climate change' will now have to be implemented.

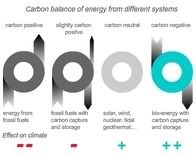

These strategies draw on carbon-negative bioenergy and biofuels, specially designed for the worst case scenario of abrupt climate change. The IPCC therefor explicitly recognizes the concept of 'bio-energy with carbon storage' (also known as BECS, negative emissions energy or as 'biomass coupled to CCS') as well as techniques aimed at increasing soil carbon storage. Through biochar and terra preta systems, the latter objective can be coupled to the production of carbon-negative biofuels, which effectively store carbon in soils.

The IPCC says that without extra measures, carbon dioxide emissions will continue to rise; they are already growing faster than a decade ago, partly because of increasing use of coal. The IPCC's economic analyses say that trend can be reversed at reasonable cost.

In the section on mitigation, the scientists of the IPCC present key mitigation options per economic sector. The bioeconomy is called on to play a major role in all of the sectors contributing to global warming - from the use of energy crops to replace fossil fuels, over biofuels for transport, to biogas production from manure and to biomass coupled to carbon capture and storage. An overview:

Biofuel blending policies and CO2 standards for road transport are seen as policies that have shown to be environmentally effective. Likewise, a reduction of fossil fuel subsidies and taxes or carbon charges on fossil fuels are instruments that can contribute. For renewable power and heat, feed in tariffs, renewable energy obligations and producer subsidies have been shown to work to promote their uptake.

Most importantly, the IPCC scientists finally recognize carbon-negative energy, also known as 'biotic CCS', 'bio-energy with carbon storage' or 'negative emissions energy'. This most radical of emission reduction concepts is based on coupling bioenergy and biofuel systems to carbon capture and storage (CCS). Nuclear power, ordinary biofuels or renewables like wind and solar power are all 'carbon-neutral' at best, that is, they do not add new CO2 to the atmosphere. Carbon-negative bioenergy and biofuels go much further: they take historic emissions out of the atmosphere.

Scientists have been calling for equal opportunities for biotic CCS and negative emissions biofuels. See for example Stefan Grönkvist, Kenneth Möllersten and Kim Pingoud's article: "Equal Opportunity for Biomass in Greenhouse Gas Accounting of CO2 Capture and Storage: A Step Towards More Cost-Effective Climate Change Mitigation Regimes" published recently in Mitigation and Adaptation Strategies for Global Change. The IPCC scientists have finally taken their collegues' call to heart:

In agriculture, improved crop and grazing practises to enhance soil carbon storage are called on. One of the prime techniques to achieve this is to convert energy crops into biofuels while retaining part of their biomass in the form of biochar which is then sequestered in soils. This is an effective technique not only to add carbon to soils, but to strengthen their capacity to retain organic carbon.

Morever, these carbon-negative biofuels and their biochar component have shown to reduce fertilizer needs for crops, to result in more efficient utilization of fertilizers and to improve the efficiency of water use in agriculture. These two demands - improved efficiency in the use of fertilizers and water - are seen by the IPCC as important instruments to reduce the carbon footprint and inefficiency of agriculture.

Livestock and manure management to reduce methane (CH4) levels too forms an important mitigation strategy, which implies, amongst other things, applications for the production of biogas from manure.

Finally, the IPCC scientists also call for the production of dedicated energy crops to replace fossil fuel use. A lot of work from the scientific community is going into the development of next generation energy crops. And many energy plantations aimed at producing biomass as substitute for fossil fuels are being established.

In the forestry sector, the IPCC again sees the utilization of forestry resources for bioenergy as a key global warming mitigation strategy. It specifically points at the development of tree species with improved carbon storage capacity. The first of these special trees have meanwile been engineered - Eucalyptus (previous post), a prime tropical energy crop, and Dahurian Larch, found in Northeastern Asia and Siberia (more here). When such trees which take more carbon dioxide out of the atmosphere are coupled to carbon-negative bioenergy and biofuel production, a giant leap towards radically negative emissions energy and fuel systems can be obtained (and the era of fourth generation biofuels would be opened.)

Last but not least, the bioeconomy is set to play a key role in the waste management sector. Biogas from landfills is seen as a mitigation option, as is controlled waste water treatment, which allows the use of bioenergy production by means of Microbial Fuel Cells (MFCs) which purify water while generating energy from the waste it contains. Finally, the use of biocovers and biofilters is encouraged to optimise CH4 oxidation.

Turning to the developing world, improved cooking stoves are seen as key to reduce the contribution of poor households to global warming. Biopact reports regularly on this subject: the replacement of open fires by efficient biogas cooking systems or improved stoves for the use of modern biofuels (such as ethanol gelfuels, biopropane, or biokerosene) could make a direct difference in improving the health of millions of women and children in poor rural households, as well as reducing the unsustainable use of forest and wood resources, and the emissions generated by these primitive forms of energy use.

In the industrial sector, two main suggestions imply a role for the bioeconomy. First and foremost the substitution of carbon-intensive materials by more renewable ones (e.g. biopolymers for the production of plastics, instead of petroleum).

Secondly, and this is a field of growing interest to the bioenergy community, the replacement of fossil fuels by biofuels in the large industrial sectors like the cement, and iron industry. Major initiatives are underway to utilize biomass instead of coal in these sectors, with the added advantage that if their CO2 emissions are captured and sequestered (CCS), negative emissions energy becomes possible once again. For examples of the substitution of coal by biomass in the cement industry, see here and here. For a large EU-funded research project into the use of biomass for the production of green iron and steel, named ULCOS (Ultra Low CO2 Steelmaking), see this previous post.

The IPCC thus sees an important role for the bioeconomy to contribute to a reduction of greenhouse gas emissions, in all economic sectors held responsible for climate change.

The panel's scientists say the reversal to a low carbon economy needs to come within a decade if the worst effects of global warming are to be avoided.

The findings will now feed into the Bali talks on the UN climate convention and the Kyoto Protocol which open on 3 December.

References:

Intergovernmental Panel on Climate Change: Summary for Policymakers of the AR4 Synthesis Report [*.pdf] - November 17, 2007.

The three previous Fourth Assessment Report publications by the IPCC's three working groups are discussed here:

Biopact: IPCC Fourth Assessment Report: climate change 'very likely' caused by humans - [Working Group I], February 02, 2007

Biopact: IPCC Fourth Assessment Report: current and future impacts of climate change on human and natural environments - [Working Group II], April 06, 2007

Biopact: IPCC Fourth Assessment Report: mitigation of climate change - [Working Group III], May 04, 2007

On carbon-negative biofuels and bioenergy, see:

The studies by the Abrupt Climate Change Strategy (ACCS) group.

Peter Read and Jonathan Lermit: "Bio-Energy with Carbon Storage (BECS): a Sequential Decision Approach to the threat of Abrupt Climate Change", Energy, Volume 30, Issue 14, November 2005, Pages 2654-2671.

Noim Uddin and Leonardo Barreto, "Biomass-fired cogeneration systems with CO2 capture and storage", Renewable Energy, Volume 32, Issue 6, May 2007, Pages 1006-1019, doi:10.1016/j.renene.2006.04.009

Stefan Grönkvist, Kenneth Möllersten, Kim Pingoud, "Equal Opportunity for Biomass in Greenhouse Gas Accounting of CO2 Capture and Storage: A Step Towards More Cost-Effective Climate Change Mitigation Regimes", Mitigation and Adaptation Strategies for Global Change, Volume 11, Numbers 5-6 / September, 2006, DOI 10.1007/s11027-006-9034-9

Christian Azar, Kristian Lindgren, Eric Larson and Kenneth Möllersten, "Carbon Capture and Storage From Fossil Fuels and Biomass – Costs and Potential Role in Stabilizing the Atmosphere", Climatic Change, Volume 74, Numbers 1-3 / January, 2006, DOI 10.1007/s10584-005-3484-7

David Tilman, Jason Hill, Clarence Lehman, "Carbon-Negative Biofuels from Low-Input High-Diversity Grassland Biomass", Science, 8 December 2006: Vol. 314. no. 5805, pp. 1598 - 1600, DOI: 10.1126/science.1133306

James S. Rhodesa and David W. Keithb, "Engineering economic analysis of biomass IGCC with carbon capture and storage", Biomass and Bioenergy, Volume 29, Issue 6, December 2005, Pages 440-450.

Further reading:

Biopact: IPCC to warn of 'abrupt' climate change: emergency case for carbon-negative biofuels kicks in - November 16, 2007

Biopact: Carbon-negative bioenergy is here: GreatPoint Energy to build biomass gasification pilot plant with carbon capture and storage - October 25, 2007

Biopact: A quick look at 'fourth generation' biofuels - October 08, 2007

Biopact: Green steel made from tropical biomass - European project - February 08, 2007

Article continues

posted by Biopact team at 4:46 PM 0 comments links to this post