U.S. Forest Service: ethanol from forests can replace 15 percent of gasoline

Kimbell presented the proposal in a speech before the Society of Environmental Journalists in San Francisco. These are ambitious goals, and they would take a concerted national effort to reach.

New biofuel technologies

According to Kimbell, with the technologies now becoming available, the U.S. could replace as much as 15 percent of its current gasoline consumption with ethanol from wood — and not just any wood, but 'unhealthy' wood that is not being used for other purposes and that must be removed from forests to prevent wildfires. Second-generation biofuel technologies capable of converting this type of woody biomass consist of biochemical and thermochemical conversion techniques.

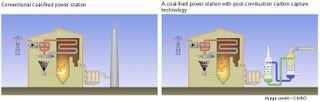

Of these technologies, the thermochemical pathway known as pyrolysis is most advanced and cost-effective. But biochemical conversion techniques, based on enzymes that succeed in breaking down lignocellulosic biomass, are receiving a great deal of research and investment. Alternative routes consist of gasifying wood and converting the syngas via Fischer-Tropsch synthesis into ultra-clean synthetic biofuels.

The wood for ethanol would come mainly from undergrowth that the 'healthy forests' law now requires to be removed to prevent wildfires. The Healthy Forests Initiative contains a variety of provisions to speed up such hazardous-fuel reduction and forest-restoration projects on specific types of Federal land that are at risk of wildland fire and of insect and disease epidemics.

A lot of our forests across our country are unhealthy because they're overstocked. There's a lot of unhealthy underbrush. That's where we're talking about getting the bioenergy from. It's from the reduction of flammable fuels in the forests — instead of just burning it up in piles or grinding it up. - Allison Stewart, spokeswoman U.S. Forest ServiceBesides use for the production of liquid fuels, small-diameter trees and underbrush can also be used as solid biofuels to heat homes and to generate renewable electricity.

Questions

The biofuel plan is ambitious and it is not clear how the biomass logistics would work out. Thinning forests and removing underbrush is labor intensive and transporting this low energy density biomass to central biofuel facilities would probably be uneconomic.

However, several innovations have seen the light that allow for a decentralised production system. New forest residue harvesters integrated with wood chippers have been developed (earlier post), as have mobile pellet plants. Small, modular pyrolysis plants can be located close to the source of the biomass (more here). There, the wood would be transformed into bio-oil with a higher energy density. This oil can then be transported more efficiently to a central biorefinery that refines the pyrolysis oil into specific fuels ready for use in cars:

energy :: sustainability :: ethanol :: synthetic biofuels :: pyrolysis :: Fischer-Tropsch :: forestry :: wildfire :: biomass ::

energy :: sustainability :: ethanol :: synthetic biofuels :: pyrolysis :: Fischer-Tropsch :: forestry :: wildfire :: biomass :: The Forest Service estimates that America's forests — both public and private — offset about 10 percent of carbon emissions in the United States. Kimbell proposes a national effort to double that amount by 2020. The Forest Service manages 155 national forests and 20 national grasslands — an area equivalent to the size of Texas.

While producing biofuels, the Forest Service will at the same time be "doing a lot of replanting of new forests, where there are no forests now." Most of those are in areas cleared out by wildfires, floods and other calamities of nature.

Trees absorb carbon dioxide, but the science for measuring how much is unsettled. Some have suggested forests in temperate climates contribute to climate change, whereas grasslands would do more to reduce global warming.

Despite these uncertainties, the Forest Service is teaming up with the nonprofit National Forest Foundation to allow consumers to participate in a voluntary program to "offset" their carbon dioxide emissions by making charitable contributions that will be used to plant trees and do other work to improve national forests. Several such reforestation projects have been identified in the Custer National Forest in Montana and South Dakota and in the Payette National Forest in Idaho.

Picture: Fire Behavior in a small area that was thinned: fire burns low and on the ground. The U.S. Forest Service now proposes to utilize the removed underbrush and thinnings for the production of biofuels.

References:

Associated Press: Forest Chief Touts Ethanol to Power Cars - September 8, 2007.

KSBY: Forest Service chief urges using forests to power cars on ethanol - September 8, 2007.

Forests and Rangelands, official site of the U.S. Healthy Forests Initiative.

Biopact: Efficient timber harvester delivers wood chips on the spot, improves biomass logistics - August 19, 2007

Biopact: The mobile pellet plant - April 29, 2007

Biopact: Dynamotive begins construction of modular fast-pyrolysis plant in Ontario - December 19, 2006

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Delphi is

Delphi is

Australia and China have

Australia and China have

The Indian

The Indian  Brazil and Mozambique have signed six bilateral agreements on social and economic cooperation, with the most important one being a commitment to join forces on the production of biofuels. Mozambique's president Armando Guebuza is currently in Brazil where he met with his counterpart and with biofuel industry leaders. Brazilian president Lula Inácio Lula da Silva has been extremely active in trying to help Africa benefit from its large biofuels potential. Promoting renewable fuels abroad has become his administration's top foreign policy priority.

Brazil and Mozambique have signed six bilateral agreements on social and economic cooperation, with the most important one being a commitment to join forces on the production of biofuels. Mozambique's president Armando Guebuza is currently in Brazil where he met with his counterpart and with biofuel industry leaders. Brazilian president Lula Inácio Lula da Silva has been extremely active in trying to help Africa benefit from its large biofuels potential. Promoting renewable fuels abroad has become his administration's top foreign policy priority.

The Drax Group, which runs Europe's largest coal-fired power station, has

The Drax Group, which runs Europe's largest coal-fired power station, has

Catalyzing an entire new industry for North Carolina is the long-term task of the newly established

Catalyzing an entire new industry for North Carolina is the long-term task of the newly established  Clean technology chemistry company Reaction Design today

Clean technology chemistry company Reaction Design today  The U.S. House of Representatives has passed legislation seeking to improve federal coordination, dissemination and investment in green chemistry research and development. The Green Chemistry Research and Development Act of 2007 (

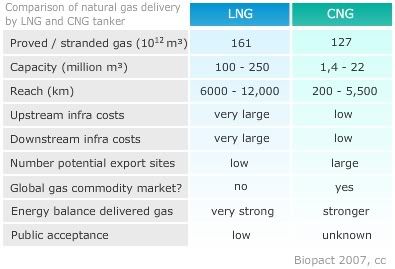

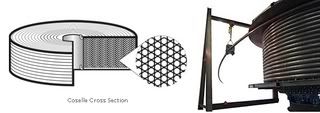

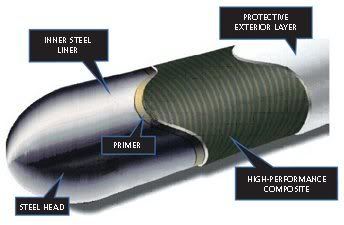

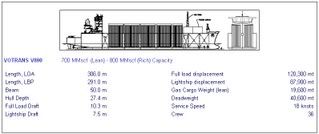

The U.S. House of Representatives has passed legislation seeking to improve federal coordination, dissemination and investment in green chemistry research and development. The Green Chemistry Research and Development Act of 2007 ( At present, the only way to transport natural gas is by pipeline or by LNG tanker. However, several organisations are designing a new class of ships that would transport natural gas in a compressed form. Such CNG carriers could tap so-called 'stranded gas' resources and bring them to nearby markets in a fairly uncomplicated way. Even though the concept of marine CNG transport has a long history, new technologies, high gas prices, recent geopolitical developments, the need for more flexible supply contracts and a global shift away from dirty fossil fuels to cleaner natural gas, have brought it back into the spotlight.

At present, the only way to transport natural gas is by pipeline or by LNG tanker. However, several organisations are designing a new class of ships that would transport natural gas in a compressed form. Such CNG carriers could tap so-called 'stranded gas' resources and bring them to nearby markets in a fairly uncomplicated way. Even though the concept of marine CNG transport has a long history, new technologies, high gas prices, recent geopolitical developments, the need for more flexible supply contracts and a global shift away from dirty fossil fuels to cleaner natural gas, have brought it back into the spotlight.

According to the

According to the  Scientists from the University of California Irvine (UCI) and

Scientists from the University of California Irvine (UCI) and  In a very interesting development, India's TVS Motor is

In a very interesting development, India's TVS Motor is

Origo Sino-India Plc, an investment and strategic advisory company focused on the private equity markets of China and India, has

Origo Sino-India Plc, an investment and strategic advisory company focused on the private equity markets of China and India, has

The growing popularity of palm oil has been condemned by some conservationists from the West who see rainforest being given over to palms in Malaysia and Indonesia, with an appreciable loss in biodiversity. The push to plant more trees is easy to explain: palm oil is by far the most productive oil and energy crop and brings nearly instant profits to millions of small farmers and estates alike. Palm oil is one of the few sectors that bring social and economic development to poor communities in a straightforward way.

The growing popularity of palm oil has been condemned by some conservationists from the West who see rainforest being given over to palms in Malaysia and Indonesia, with an appreciable loss in biodiversity. The push to plant more trees is easy to explain: palm oil is by far the most productive oil and energy crop and brings nearly instant profits to millions of small farmers and estates alike. Palm oil is one of the few sectors that bring social and economic development to poor communities in a straightforward way.

Saturday, September 08, 2007

Germany's Biostrom Energy Group to build 10 biogas plants to feed renewable gas into national grid

According to this agreement, the modular plants, with an output of 10 times 500 KW will be constructed from the middle of 2008 in Energiepark Linthe near Potsdam (southwest of Berlin). Biostrom Energy Group AG is currently constructing 17 plants with total output of 8.5 MW. The gas produced in the ten biogas plants in Linthe will be of natural gas quality and will be fed into the national gas grid.

Biogas is a mixture of gases which result from the anaerobic microbial decomposition of organic substances, of which 50-70% is methane – a top-quality energy source. Additional components are carbon dioxide (CO2) as well as traces of hydrogen sulfide (H2S), Nitrogen (N2), Hydrogen (H2) and carbon monoxide (CO). By upgrading and cleaning these components out of biogas, biomethane of natural gas quality can be obtained. When this renewable and carbon-neutral gas is fed into the main pipelines, it can be used for a range of end-uses, from home use to powering CNG-cars. Germany recently started looking into opening up the country's entire gas grid to accomodate biogas (more here and here).

Biostrom will supply the biogas plants with substrates obtained from dedicated energy crops. For this purpose, the company has taken out long-term leases on agricultural land. The 20-year leases will safeguard the supply of maize silage for the ten 500 kW biogas plants. Supplies for the CarboCompact plants - which include wood chips - will come from third parties:

BKN BioKraftstoff Nord AG has specialized in project development for biogas plants and the production of biodiesel. Thanks to Biostrom Energy Group AG and its operating subsidiaries, which BKN successfully acquired in April, BKN now operates successfully on the market for biogas plants as a prime contractor, covering the entire value chain: from maintaining competitiveness standards for plant locations to project planning, permit acquisition, construction and operation of biogas plants as well as the efficient control of the plants.

Biological process control for biogas plants, supported by Biostrom’s know-how, is one of its particular assets. BKN's subsidiary BioDiesel Bokel GmbH, which stemmed from an agricultural distillery cooperative, currently has a capacity to produce around 50,000 t/year of biodiesel. The company has already substantially increased its revenues and earnings over the past few years.

References:

Biopact: Germany considers opening natural gas network to biogas - major boost to sector - August 11, 2007

Biopact: EU research project looks at feeding biogas into the main natural gas grid - April 08, 2007

Article continues

posted by Biopact team at 4:10 PM 0 comments links to this post