Kenya's first ethanol plant may help local sugar industry

A multi-million-shilling company will be set up in the Homa Bay District, in Kenya's Nyanza Province, to manufacture ethanol from sugar.

A multi-million-shilling company will be set up in the Homa Bay District, in Kenya's Nyanza Province, to manufacture ethanol from sugar. The announcement by Kenya Sugar Board chief executive officer Andrew Otieno comes at a time sugar production in the country is threatened by cheap imports from the Common Market for East and Southern Africa (Comesa), which has created a free market in the region. Under the COMESA Sugar Safeguard Protocol, a quantitative restriction on imports into the Kenyan market will expire in 2008, which may facilitate higher imports, potentially causing injury to local sugar farmers.

Drawing on numbers of to the Kenya Sugar Board, the FAO estimates [*.pdf] nearly 6 million people derive their livelihoods from the sugar industry, either directly through sugarcane production, sugar manufacturing and distributive activities, or indirectly through the allied economic activities. The sugar milling factories and the sugarcane plantations owned by the factories have employed between 43,000 and 75,000 people in Kenya over the last ten years.

Kenya's sugarcane industry also contributes significantly to the revenue of both the local authorities and the central government in the form of the value-added tax, sugar development levy and local authority levies.

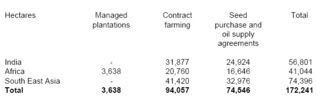

Kenya produces about 450,000 tonnes of sugar annually with at around 620,000 tonnes. Therefore, the shortfall must be met by imports (graph, click to enlarge). Since domestic sugar milling factories produce only raw sugar, industrial users of refined sugar always depend on imports for their manufacturing requirements.

The construction of a local ethanol plant may boost offtake of the raw sugar and replace investments needed to build sugar refining capacity. Otieno spoke to reporters about the ethanol factory when he led a team to assess the site of the proposed company.

The project is the first of its kind in East and Central Africa and only the second to be established in the Comesa region after Mauritius. The ethanol plant, funded by Fair Energy SA, a European company based in Geneva, is to be modelled on the Mauritius 'flexi-sugar' industry, which, besides being efficient, boasts the best-paid farmers and is based on a highly integrated production chain:

bioenergy :: biofuels :: energy :: sustainability :: ethanol :: sugar cane :: trade :: COMESA :: Kenya ::

bioenergy :: biofuels :: energy :: sustainability :: ethanol :: sugar cane :: trade :: COMESA :: Kenya :: Fair Energy SA also manages Kenana Sugar Company in Sudan and businesses in Nigeria. Kenana recently announced it will invest in Sudan's sugar sector with an eye on ethanol.

"The new flexi-sugar company will be fully private but local interest is welcome in acquisition of equity in the structure of the company," Otieno said. "The Sugar Act provides for 50 per cent farmer ownership of mills but this has not been possible in Kenya due to lack of finances."

The board has promised to open up opportunities for farmers to begin with small acquisitions of the company stake through deductions from earnings that would gradually grow to substantial ownership.

"Ethanol is targeted for the export market because Kenya does not have a policy supporting its use as fuel," Otieno added.

References:

The Nation (Nairobi), via AllAfrica: Kenya: Firm to Produce Ethanol From Sugar - June 27, 2007.

FAO Briefs on Import Surges - Countries No. 7: Kenya: dry milk powder, sugar, maize [*.pdf]- February, 2007.

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

The Renewable Energy and Energy Efficiency Partnership (REEEP), a leading alliance promoting clean energy in the developing world,

The Renewable Energy and Energy Efficiency Partnership (REEEP), a leading alliance promoting clean energy in the developing world,

A team of made up of nine professors and seven post-doctoral fellows at the University of California, San Diego, Davis and Berkeley

A team of made up of nine professors and seven post-doctoral fellows at the University of California, San Diego, Davis and Berkeley  In an important step for the production of biofuels in the Global South, D1 Oils plc, the UK-based producer of biodiesel,

In an important step for the production of biofuels in the Global South, D1 Oils plc, the UK-based producer of biodiesel,

A major breakthrouh in the life sciences was published in the journal

A major breakthrouh in the life sciences was published in the journal  Dr. Lartigue and her team is excited by the results of the research, and the scientists are continuing to perfect and refine the techniques and methods as they move to the next phases and prepare to develop a fully synthetic chromosome.

Dr. Lartigue and her team is excited by the results of the research, and the scientists are continuing to perfect and refine the techniques and methods as they move to the next phases and prepare to develop a fully synthetic chromosome.

At a time when a major

At a time when a major

UOP, formed its Renewable Energy & Chemicals business unit in late 2006 to commercialize solutions for production of renewable biofuel energy. At that time, UOP announced it has developed, along with European energy company Eni, a hydroprocessing technique to convert vegetable oils and waste into a high-cetane green diesel fuel with low emissions and high efficiency. The process, called UOP/Eni Ecofining, uses existing refinery infrastructure and technology. Earlier this month, UOP announced Eni will build the first Ecofining facility in Italy. The facility is projected to start up in early 2009 (

UOP, formed its Renewable Energy & Chemicals business unit in late 2006 to commercialize solutions for production of renewable biofuel energy. At that time, UOP announced it has developed, along with European energy company Eni, a hydroprocessing technique to convert vegetable oils and waste into a high-cetane green diesel fuel with low emissions and high efficiency. The process, called UOP/Eni Ecofining, uses existing refinery infrastructure and technology. Earlier this month, UOP announced Eni will build the first Ecofining facility in Italy. The facility is projected to start up in early 2009 ( DuPont and Denmark-based

DuPont and Denmark-based

Thailand's ethanol producers are currently facing a surplus and want to export their biofuel (

Thailand's ethanol producers are currently facing a surplus and want to export their biofuel ( The World Wildlife Fund (WWF) today

The World Wildlife Fund (WWF) today

According to BBC Brasil, a Chinese state-owned enterprise and a Brazilian group have

According to BBC Brasil, a Chinese state-owned enterprise and a Brazilian group have

The U.S. Department of Energy (DOE) Secretary Samuel W. Bodman

The U.S. Department of Energy (DOE) Secretary Samuel W. Bodman  Despite Fidel Castro's criticism of ethanol made from corn (mainly aimed at the US), Cuba itself is investing heavily in producing the biofuel (

Despite Fidel Castro's criticism of ethanol made from corn (mainly aimed at the US), Cuba itself is investing heavily in producing the biofuel ( With biodiesel production in the EU and the US at an all-time high and a record number of new biodiesel plants under construction, the industry is facing an impending crisis over waste glycerin, the major byproduct of biodiesel production. New

With biodiesel production in the EU and the US at an all-time high and a record number of new biodiesel plants under construction, the industry is facing an impending crisis over waste glycerin, the major byproduct of biodiesel production. New

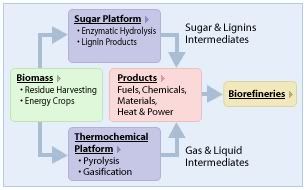

We have often pointed to the potential modern bioenergy offers for rural poverty alleviation. Around 2 billion people in the developing world still rely on primitive, dangerous and wasteful biomass technologies for energy (like burning fuel wood on open fires). However, the very presence of these resources makes leapfrogging beyond fossil fuels and towards modern biofuels possible.

We have often pointed to the potential modern bioenergy offers for rural poverty alleviation. Around 2 billion people in the developing world still rely on primitive, dangerous and wasteful biomass technologies for energy (like burning fuel wood on open fires). However, the very presence of these resources makes leapfrogging beyond fossil fuels and towards modern biofuels possible.

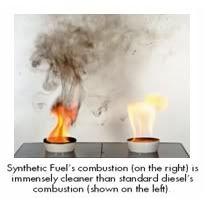

The development of ultra-clean synthetic fuels has been speeding up lately, with the first pilot plants actually coming online and a series of cooperation agreements being signed between major research organisations. A new initiative is now joining the forces of some of Europe's leading automotive and fuel supply companies into the

The development of ultra-clean synthetic fuels has been speeding up lately, with the first pilot plants actually coming online and a series of cooperation agreements being signed between major research organisations. A new initiative is now joining the forces of some of Europe's leading automotive and fuel supply companies into the

Scientists from the U.S. Department of Agriculture's Agricultural Research Service (ARS) are

Scientists from the U.S. Department of Agriculture's Agricultural Research Service (ARS) are  At the Biopact, we share the Afro-optimist philosophy which holds that African countries can 'leapfrog' beyond the petroleum era and immediately enter a new bright green world without going through a dirty development stage first. This is possible because African countries are not burdened by fossil fuel based industries, mentalities and infrastructures.

At the Biopact, we share the Afro-optimist philosophy which holds that African countries can 'leapfrog' beyond the petroleum era and immediately enter a new bright green world without going through a dirty development stage first. This is possible because African countries are not burdened by fossil fuel based industries, mentalities and infrastructures.

CantorCO2e Limited, a provider of financial services to the world’s environmental and energy markets,

CantorCO2e Limited, a provider of financial services to the world’s environmental and energy markets,  With research backgrounds ranging from materials engineering to molecular biophysics, seventeen leading scientists from around the world issued a statement today

With research backgrounds ranging from materials engineering to molecular biophysics, seventeen leading scientists from around the world issued a statement today  Braskem, the leading company in Latin America's thermoplastic resins segment and Brazil's second largest privately owned industrial company,

Braskem, the leading company in Latin America's thermoplastic resins segment and Brazil's second largest privately owned industrial company,  The University of Georgia's Center for Agribusiness and Economic Development is part of a growing effort in the U.S. to study sorghum as a biomass crop for second-generation cellulosic biofuels (

The University of Georgia's Center for Agribusiness and Economic Development is part of a growing effort in the U.S. to study sorghum as a biomass crop for second-generation cellulosic biofuels (

Saturday, June 30, 2007

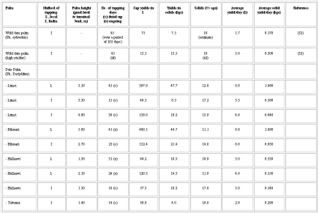

Interview: DaimlerChrysler, farmers see great future in jatropha

Germany's NTV conducted an interview [*German] with professor Klaus Becker, leader of the projects and director of Tropenzentrums (Tropical Agriculture) of the University of Hohenheim, revealing why the crop is attracting so much attention (e.g. oil giant BP and D1Oils recently announced a global joint venture to grow the plant on a million hectares). Topics include the future of petroleum and oil prices, the social and environmental sustainability of jatropha, its potential to meet the fuel needs of the rapidly growing number of cars on the planet, climate change and new uses for the plant's oil based on the latest research.

Klaus Becker: DaimlerChrysler is interested in the crop because it will give India a high quality biodiesel that can be used directly in existing cars. We will not be establishing plantations ourselves. Initially the project was part of a marketing effort in India, but the crop has grown so popular that this has become larger than we expected. When a major company invests in such a project, people take things seriously, which is what happened with jatropha:

You were the first to research jatropha on a large scale?

We were the first in Europe. For over 15 years we have been working with a consulting firm in Nicaragua to study jatropha. The plant is 70 million years old. But nobody was interested in it. Without the DaimlerChrysler project the current jatropha-euphoria would not have emerged.

Is jatropha-oil already being used as biodiesel?

We have been trialing it for the past two and a half years. The DaimlerChrysler office in Pune coordinates the road tests. We have multiple test vehicles. This year we plan to burn 40,000 liters of jatropha biodiesel - B100, our fuel does not need to be mixed with petro-diesel. All our tests are based on 100 percent pure jatropha biodiesel.

In ordinary, non-adapted vehicles?

In fully normal Mercedes-CDIs, yes.

We hear so much about jatropha, it sounds like a wonder plant.

Well, it is a great crop.

Jatropha thrives on poor soils, but supposedly the crop even makes these soils more fertile so that other, less robust plants can be grown on it. Is that correct?

Yes it is. We have established jatropha on heavily degraded lands. After 10, 15 years we were able to win back this land, because jatropha had pushed back the effects of the erosion that had destroyed the soils. I offer money to anyone who can show me a negative aspect of cultivating jatropha.

It's a poisonous plant.

That is, the plant can protect itself against predators. Besides, many ornamental plants in Europe are more poisonous than jatropha. But jatropha is a useful crop, or better: it is becoming a useful crop and precisely because it can protect itself against grazing animals, it can be grown on poor lands. The crop doesn't need to be fenced off or protected, it is its own fence. The region in which we work - Gujarat in northwest India, Ghandi-land - is extremely poor, but rich in waste-lands.

An added advantage supposedly is the fact that the plant can not be harvested mechanically. This creates lots of jobs.

That's right. Especially the Indians think this is the most interesting aspect of the crop because it allows social and economic development in the rural areas. We are also working in Madagascar. There are regions there with unemployment rates of up to 70%. Currently there are no crops that can create a substantial number of jobs in the country - except energy crops. Most of the bioenergy crops we are accustomed to can be harvested mechanically. Jatropha on the contrary requires a large number of workers. The standard number we work with is 1.5 workers per hectare for the cultivation of the plants and for harvesting the oil seeds.

But does it make economic sense to growh jatropha if it is so labor intensive?

Yes it does, because energy prices will continue to rise. By 2030 the total number of cars on the planet's roads will have grown from 500 million today to 900 million. By then, countries like China will have overtaken the United States. Today there are 150 million cars on America's roads. In 2030 there will be 190 million in China.

But they can't all burn jatropha-oil, can they?

Quite frankly, the will burn whatever they can find. Anyone who produces any kind of energy will find a ready market for the coming 30 to 40 years, and will sell at the highest prices. For small farmers, this is a very important development: they now have a number of crops available for which the risk of overproduction does not exist - overproduction, the economic phenomenon that has been so disastrous to millions of poor farmers. With jatropha the farmers will, for the first time in their lives, find a stable market with few risks.

This brings us to climate change.

The way we produce biodiesel from jatropha in India and Africa has a strong CO2-balance. During the production of the crop we use relatively low amounts of fossil energy; much of the production consists of manual labor. This makes the balance much better than biodiesel made from, for example, rapeseed.

Well, the crop can grow wherever temperatures are high enough. It is a tropical plant. But it uses much less water than other energy crops, because of its highly efficient strategy to use water. Together with the Ministry of Agriculture and the Environment in Egypt, we are doing trials in the middle of the desert. We irrigate it with waste water from the city.

Excuse me?

Nobody believes this, until they have seen it. We grow jatropha in the middle of the desert - the desert you see in post-cards - in the sand. The crop is irrigated with waste-water. And it thrives beautifully.

Jatropha-plants in the Egyptian desert - such a miracle crop must be attracting its fair share of snake oil vendors. There are a few websites playing with the crop, but they look amateurish.

Well, when it comes to jatropha, the internet is less than amateurish. 5% of what you find is credible. There are people who ask a dollar per seed, others offer 20,000 tons of oil per month. In reality, such amounts are not yet available on the market. My estimate is that 5 million hectares of the crop are being established on a world wide scale, scattered across a vast number of countries. Only Myanmar (Burma) has made a serious effort and established 800,000 hectares over the past year (earlier post). It takes between 4 and 5 years before the plants mature. Other plantations [using improved crops] will take 3 years to reach maturity. Only then will a market for jatropha oil emerge.

In online drug stores it costs €12 for 500 milliliters of jatropha oil.

Yes, jatropha oil is currently sold at that kind of quantities. In Mali, women sell jatropha based soap, very nice soap. In the past the famous Savon de Marseille was made from jatropha oil. The plant yields more than just oil, you see. We are investigating how we can turn jatropha press cakes (the residues that remain after the oil has been extracted) into animal fodder. We are researching how to remove the toxic substances from the meal. If we succeed, we can replace soybean meal, because the quality of jatropha-meal is better. Soja's raw protein content is around 45%; jatropha's is 60%. The only problem is the detoxification step that must be developed. But we are confident that we will pull it off. Even the toxic substance in jatropha, Phorbolester, is valuable. It is being used in cancer research. We want to develop a bio-pesticide from it - a natural product that can be used by organic farmers.

Where will the market for jatropha oil emerge first? In India?

The Indians need everything they produce. The Chinese too have large plans for jatropha; they are looking at establishing 13 million hectares of plantations by 2020.

When will we in Europe be utilizing jatropha-oil?

That's a matter of market policies and economics. Producers will sell to those who offer the best price. It's as simple as that.

But this depends on the evolution of the oil price, doesn't it?

The same is true for labor. Until the 1980s, the number of jobs and economic development was strongly correlated in Europe. Today share prices rise when companies cut jobs. In Africa and India the opposite is true - the situation there is the same as in Europe 30 years ago.

Does jatropha-oil offer the possibility to replace other petrochemical products?

Yes, very much so. From hydraulic oil to motor oil - for these purposes all plant oils are clearly better than mineral oils .

What about heating oil?

No problem. If you use jatropha biodiesel you don't need to build a protection wall around your tank. Contrary to petroleum based heating oil, biodiesel readily biodegrades in the soil. Biodiesel is ranked in class 1, petrodiesel in class 5 [German classes for fuel oil for home heating].

How to invest in jatropha?

Currently there are some serious investors active in Germany, Colombia, Indonesia and other countries. I'm not allowed to name names. But these investors will soon go public.

How many research projects you would qualify as 'serious' are currently underway?

Oil firm BP has been building on our research in India and has launched research activities there. [Note: the interview was conducted before the announcement of BP's joint venture with D1Oils]. Many universities now have jatropha research groups. At the Dutch University of Wageningen [Europe's leading agronomic university] there are 5 PhD theses being written as we speak. My estimate is that world-wide there are around 1,000 serious research groups working on jatropha. Over the coming years, the crop will reveal many of its secrets. Today, it remains a wild plant.

Translated and adapted by Jonas Van Den Berg and Laurens Rademakers.

References:

NTV: "Jatropha kann man nichts Schlechtes anhängen" - June 29, 2007.

DaimlerChrysler:Öl vom Ödland - Das Jatropha-Projekt in Indien - Jatropha project website.

Jua Katika Mbinga - Sonne über Mbinga [Sun over Mbinga], jatropha project in Tanzania funded by Germany's Energy Agency.

Article continues

posted by Biopact team at 3:43 PM 0 comments links to this post