UN environment chief backs EU's biofuels plan, urges environmentalists to drop 'simplistic' views

The UN’s top environment official has backed an ambitious European Union plan to require the blending of plant-based biofuels into road fuels despite what he calls "simplistic" critiques by some environmentalists that this will automatically lead to increased deforestation in south-east Asia and Brazil.

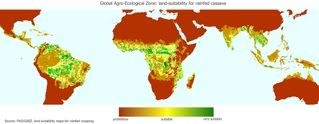

The UN’s top environment official has backed an ambitious European Union plan to require the blending of plant-based biofuels into road fuels despite what he calls "simplistic" critiques by some environmentalists that this will automatically lead to increased deforestation in south-east Asia and Brazil.Achim Steiner, head of the UN Environment Programme (UNEP), said on Thursday that biofuels were needed to reduce global dependence on fossil fuels. Increased consumer awareness, he said, would eventually force producers of palm oil and soya used in biofuels to adopt more sustainable production methods, while other biofuel feedstocks with a far lower environmental footprint [sorghum, cassava, jatropha, sweet potatoes, sugarcane and second generation biofuels] will be adopted more widely in the future.

The top expert said curbing greenhouse gas emissions by using biofuels is one of the most effective means to fight climate change and to reduce poverty in the South. Not investing in green fuels may result in far bigger ecological damages than some of the environmentalists think. Dependence on fossil fuels is detrimental to the economy of poor countries and fuels poverty, which results in increased pressures on the environment. Biofuels can turn this situation around.

The top environment chief of the UN, who attended a meeting on business and the environment in Singapore on Thursday, suggested these environmentalists' efforts to curb biofuel development reflected a “sledgehammer” approach and were based on “simplistic” views:

bioenergy :: biofuels :: energy :: sustainability :: ethanol :: biodiesel :: greenhouse gas emissions :: climate change :: energy dependence :: poverty alleviation :: UNEP ::

bioenergy :: biofuels :: energy :: sustainability :: ethanol :: biodiesel :: greenhouse gas emissions :: climate change :: energy dependence :: poverty alleviation :: UNEP :: One of the returning points of critique made by some environmentalist groups is that the production of some biofuel feedstocks (palm oil, soya) leads to deforestation. But Mr Steiner said there were multiple causes for the burning of forest land, including clearing space for agriculture, and that biofuels should not be solely blamed for the problem.

Plant-based biofuels have been promoted to help fight global warming, and south-east Asian countries, particularly Indonesia and Malaysia, are expanding production of palm oil as a main ingredient in their production.

Palm oil plantation companies have been blamed for burning down forests in Indonesian Sumatra and Borneo and so contributing to a growing annual smog problem in the region. A recent UK-funded report found Indonesia was the world’s third-largest carbon emitter behind the US and China, largely because of the forest fires.

Even though these findings are scientifically incorrect, because they do not take into account the carbon sequestered in palm oil plantations which neutralise the carbon emitted by forest clearance, Mr Steiner acknowledged Indonesia could do more to protect forests and promote sustainable development. But he said biofuel consumers in Europe and elsewhere were becoming aware of the problem and would demand that biofuel producers be certified as engaging in sustainable production.

The UN Environment Chief predicted that biofuel producers and governments would co-operate in establishing international standards to certify sustainable production. A group of palm oil producers recently formed the Roundtable on Sustainable Palm Oil to set up a certification process, while palm oil producers in south-east Asia and soya producers in Brazil have established partnerships with environmental groups to develop sustainable criteria.

More information:

Financial Times: UN backs biofuel despite fears of deforestation - April 20, 2007.

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

French group Air Liquide, the leading producer of industrial gas technologies, has

French group Air Liquide, the leading producer of industrial gas technologies, has  The bacterium

The bacterium

Hitofumi Abe did

Hitofumi Abe did

According to the Bioenergy Network of Excellence, research and education in the field of bioenergy is speeding up in Europe, with major universities across the EU now offering 60 dedicated masters and PhD programs (

According to the Bioenergy Network of Excellence, research and education in the field of bioenergy is speeding up in Europe, with major universities across the EU now offering 60 dedicated masters and PhD programs ( Finnish oil major Neste Oil, in which the government of Finland holds a majority stake, is looking into using

Finnish oil major Neste Oil, in which the government of Finland holds a majority stake, is looking into using

MIT researchers say they

MIT researchers say they  India's

India's  China is building a new coal-fired power plant each week. The country knows that, at this pace, it will become the largest emitter of greenhouse gases, surpassing the US earlier than expected (by 2010-2015). For this reason, the People's Republic tries to diversify away from fossil fuels and into renewables, even though energy demand is so high that the green initiatives do not seem to make much difference yet. Eighty percent of the country's electricity is currently generated from coal. Demand for the climate destructive fuel increases by around 4.2% per annum.

China is building a new coal-fired power plant each week. The country knows that, at this pace, it will become the largest emitter of greenhouse gases, surpassing the US earlier than expected (by 2010-2015). For this reason, the People's Republic tries to diversify away from fossil fuels and into renewables, even though energy demand is so high that the green initiatives do not seem to make much difference yet. Eighty percent of the country's electricity is currently generated from coal. Demand for the climate destructive fuel increases by around 4.2% per annum.

What's more, the polymer is entirely made from renewable castor oil, derived from seeds of

What's more, the polymer is entirely made from renewable castor oil, derived from seeds of  While most of the world is scrambling after corn and sugar for answers to its renewable energy needs, many developing countries are focusing on a lesser known plant — cassava, also known as manioc. A new study for the first time calculates the net energy value ('NEV', 'energy balance') of cassava ethanol and finds that the tropical starchy tuber makes for a highly efficient source of renewable energy.

While most of the world is scrambling after corn and sugar for answers to its renewable energy needs, many developing countries are focusing on a lesser known plant — cassava, also known as manioc. A new study for the first time calculates the net energy value ('NEV', 'energy balance') of cassava ethanol and finds that the tropical starchy tuber makes for a highly efficient source of renewable energy.

Ethanol is widely touted as an eco-friendly, clean-burning fuel that reduces carbon dioxide emissions and thus helps mitigate catastrophic climate change. But if every vehicle in the United States ran on fuel made primarily from ethanol instead of pure gasoline, a side-effect would be that the number of respiratory-related deaths and hospitalizations would likely increase, according to a new study by Stanford University atmospheric scientist Mark Z. Jacobson. His findings are published in the April 18 online edition of the journal

Ethanol is widely touted as an eco-friendly, clean-burning fuel that reduces carbon dioxide emissions and thus helps mitigate catastrophic climate change. But if every vehicle in the United States ran on fuel made primarily from ethanol instead of pure gasoline, a side-effect would be that the number of respiratory-related deaths and hospitalizations would likely increase, according to a new study by Stanford University atmospheric scientist Mark Z. Jacobson. His findings are published in the April 18 online edition of the journal  Political instability, failed states, wars over scarce resources and millions of climate refugees are some of the 'doom-and-gloom' scenarios in a report published by a leading US military think-tank.

Political instability, failed states, wars over scarce resources and millions of climate refugees are some of the 'doom-and-gloom' scenarios in a report published by a leading US military think-tank. Leading bioenergy firm Fortum is

Leading bioenergy firm Fortum is  The Government of Netherlands has agreed to continue financing its highly successful rural biogas program, by releasing another €3.7/US$5 million. The funds will be used to build 140,000 more small biogas units for rural households nationwide.

The Government of Netherlands has agreed to continue financing its highly successful rural biogas program, by releasing another €3.7/US$5 million. The funds will be used to build 140,000 more small biogas units for rural households nationwide. Amid growing debate over the possible consequences of large-scale bioenergy production, top international experts meet at

Amid growing debate over the possible consequences of large-scale bioenergy production, top international experts meet at  Studying the energy balance of biofuels is important, certainly when they are produced from low yield crops such as corn or rapeseed. One of the main energy inputs in the production of such crops is made up by fertilizers. Earlier, we pointed to in-depth research into the fertilizer requirements of tropical energy crops, and now a study prepared for the French Enviroment and Energy Management Agency (

Studying the energy balance of biofuels is important, certainly when they are produced from low yield crops such as corn or rapeseed. One of the main energy inputs in the production of such crops is made up by fertilizers. Earlier, we pointed to in-depth research into the fertilizer requirements of tropical energy crops, and now a study prepared for the French Enviroment and Energy Management Agency (

Brazil has seen several developments in its biofuels sector recently. First of all, there was the announcement by Petrobras that it may invest in a fleet of dedicated ethanol tankers to export its rapidly growing output (

Brazil has seen several developments in its biofuels sector recently. First of all, there was the announcement by Petrobras that it may invest in a fleet of dedicated ethanol tankers to export its rapidly growing output ( Germany-based

Germany-based  A North American wood pellet race has begun, with its eyes on exports to Europe. There regulations designed to combat global climate change have created incentives for power companies to boost their use of biomass. Europe already consumes nearly 8 million tons of wood pellets a year, to run factories and power plants (see the International Energy Agency's Bioenergy Task 32 on

A North American wood pellet race has begun, with its eyes on exports to Europe. There regulations designed to combat global climate change have created incentives for power companies to boost their use of biomass. Europe already consumes nearly 8 million tons of wood pellets a year, to run factories and power plants (see the International Energy Agency's Bioenergy Task 32 on

Saturday, April 21, 2007

Shell and Powerfuel sign agreement for coal gasification and carbon capture

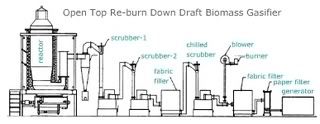

We report on this development, because it confirms our finding that of call carbon capture methods, pre-combustion carbon capture from gas is the most feasible and low-cost technology currently available. This technology can not only be applied to fossil fuels (gasified coal, natural gas) but just as well to gasified biomass or, even more interestingly, to biogas.

CCS applied to bioenergy results in a the world's only carbon negative energy system - so-called 'Bio-Energy with Carbon Storage' (BECS). Scientists think that if BECS were to be applied on a massive scale, the concept can take us back to pre-industrial CO2 levels within a few decades only. BECS effectively negates our 'historic' CO2 emissions; no other energy concept is carbon negative - renewables like solar or wind are carbon-neutral at best, whereas CCS applied to fossil fuels is slightly carbon-positive. BECS however is radically carbon-negative. Moreover, the concept is also far safer and cost-effective than risky and costly geo-engineering concepts aimed at mitigating global warming (like seeding the oceans with iron to cause artificial algae blooms, pumping sulphur into the atmosphere to create a cooling blanket, or launching millions of mirrors into space to reflect sunlight).

Finally of all CCS routes, those based on using carbon-neutral biomass are the safest; there are still considerable risks involved in storing CO2 under ground, leakage being the most problematic one. Now if the CO2 that is sequestered were to come from carbon-neutral biomass and it were to leak, there would be no net increase in the amount of carbon in the atmosphere. If sequestered CO2 derived from fossil fuels would begin to leak, the contrary would be true.

In short, for all these reasons, developments in CCS technologies are of interest to bioenergy advocates who understand the major advantages of BECS. In an earlier piece, we looked at applying carbon capture options to biomass and concluded that pre-combustion capture of CO2 from biogas is probably the most feasible path. The agreement between Shell UK and Powerfuel Plc roughly confirms this finding:

From the press release:

"Coal gasification [read 'biomass gasification'] is the cleanest method for converting coal’s [biomass's] energy potential into electricity. The process takes coal and turns it into a hydrogen-rich synthesis gas, which, in this case, will facilitate the separation of the carbon dioxide pre-combustion in the turbine generators. It is this factor which offers a lower cost approach to carbon capture. The hydrogen rich stream could also potentially be used in clean transportation and in substitution of natural gas, as well as electricity production on site."

Other, more costly carbon capture techniques are either based on trapping CO2 after combusiton of the fuel, or during the combustion.

Richard Budge, Chief Executive of Powerfuel Plc, said “We are delighted to be working with Shell in our vision to be the first commercial-scale coal fired power generator with carbon capture in the world. Success in this project would be enormously significant for UK and EU energy policy as it offers the benefits of a local, inexpensive fuel, improved security of electricity supply and very low carbon emissions. This agreement maintains our leading position in the development of carbon capture from coal fired electricity generation in the UK.”

Peter de Wit, Shell Gas & Power Executive Vice President, Global Businesses, said: “Shell is at the forefront of developments in clean coal and our leading-edge technology is clean, efficient and reliable. Today’s agreement with Powerfuel is the second we have signed in Europe in less than a year and is the first in this region for a project incorporating carbon capture and storage from the outset. The deal signals a further expansion of our clean coal business outside of China, where we have sold 15 gasification licences over the past five years.”

Powerfuel Plc has already received section 36 government consent for a part of this project. Engineering work will now proceed to the conclusion of a full FEED (front end engineering design) package, following which construction is expected to take 3 – 4 years. Discussions are continuing with third parties with a view to the construction of a pipeline to transport CO2 from Humberside, an area with very large carbon dioxide emitters, to secure storage sites in the North Sea.

Mr Budge further commented “We await the design and publication of the government’s competition to support one or more CCS projects because we believe that our project represents the lowest cost approach to the important challenges that face the electricity industry in this country and overseas.”

Article continues

posted by Biopact team at 4:41 PM 0 comments links to this post