German IT firm uses biogas fuel cell to power server farm

In a world first, German IT service firm T-Systems has taken a biogas fuel cell into operation [*German] to power and cool one of its server farms - these energy devouring machines that power our information society. The servers' electricity and cooling requirements are covered in an entirely carbon-neutral way by the 250Kw pilot system. Better still, because of the extreme efficiency of the fuel cell, T-systems is set to cut energy costs considerably. Affordable green computing power is becoming reality.

In a world first, German IT service firm T-Systems has taken a biogas fuel cell into operation [*German] to power and cool one of its server farms - these energy devouring machines that power our information society. The servers' electricity and cooling requirements are covered in an entirely carbon-neutral way by the 250Kw pilot system. Better still, because of the extreme efficiency of the fuel cell, T-systems is set to cut energy costs considerably. Affordable green computing power is becoming reality. We referred earlier to the trials with this biogas powered fuel cell. Now it is being taking into full operation. The project is a joint initiative of Power and Air Solutions, Voigt und Haeffner, and CFC Solutions GmbH, a subsidiary of MTU, supported by the German Ministry for Technology & Economy. The cell, a 'Hot Module' manufactured by CFC Solutions measures 8 by 2.5 meters and consists of three components: a gas pretreatment section that converts biomethane into hydrogen, the fuel cell, and the electricity converters that convert direct into alternating current. Coupled to the system is a cooling cell that converts the heat generated by the Hot Module (400 degrees Centigrade) into cold air used to cool the server space (image, click to enlarge).

We referred earlier to the trials with this biogas powered fuel cell. Now it is being taking into full operation. The project is a joint initiative of Power and Air Solutions, Voigt und Haeffner, and CFC Solutions GmbH, a subsidiary of MTU, supported by the German Ministry for Technology & Economy. The cell, a 'Hot Module' manufactured by CFC Solutions measures 8 by 2.5 meters and consists of three components: a gas pretreatment section that converts biomethane into hydrogen, the fuel cell, and the electricity converters that convert direct into alternating current. Coupled to the system is a cooling cell that converts the heat generated by the Hot Module (400 degrees Centigrade) into cold air used to cool the server space (image, click to enlarge).Specifications of the biogas powered Hot Module:

- System efficiency: 90%

- Electrical efficiency: 47%

- Thermal output: 180Kw

- Electrical output: 238Kw

- Coupled heat-power-cooling system

T-Systems has been enthusiastic because the extreme efficiency of the biogas powered fuel cell has allowed it to cut energy costs. The overall thermal and electrical efficiency of the system - combining heat, power and cooling - adds up to more than 90 per cent. Traditional utility power generation plants often have a capacity below 40 per cent.

Bernd Kraus, Business Process Outsourcing chief at T-Systems, says that the company currently spends 29 per cent on energy. Without the fuel cell system, these costs would increase to 38 per cent by 2010. The biogas fuel cell system allows T-Systems instead to push down costs to 20 per cent by 2010. Costs of the project are €2.5 million, partly covered by a €1 million research grant by the German Ministry of Technology and Economy.

Energy costs at the server park are high and have been increasing steeply over the past years due to rising grid electricity prices. The servers devour more energy than all of T-System's other operations. Fifty per cent goes to cooling. Moreover, as new servers keep getting stacked on racks in the same space, cooling needs per cubic meter become bigger and bigger:

biomass :: bioenergy :: biofuels :: biogas :: biomethane :: fuel cell :: servers :: Germany ::

biomass :: bioenergy :: biofuels :: biogas :: biomethane :: fuel cell :: servers :: Germany :: The biomethane for the project is produced by Schmack GmbH, a global biogas leader. The biofuel is produced locally - in Pliening near München - from dedicated energy crops. The crop in question is starch rich maize, the whole crop of which is utilized to generate approximately 5000 cubic meters of methane per hectare. This is enough methane to yield an equivalent of 50 MWh per hectare per year.

To power T-Systems' entire data center in München with biogas, around 40 to 80 of the fuel cells would be required, says Manfred Teumer, T-Systems chief for Infrastructure & Architecture Services. One entire server farm requires around 1 square kilometer of biogas maize.

An advantage of the fuel cell system is that it yields a constant amount of energy, which is exactly what is needed for server farms that do not show sudden peaks in power consumption.

In case of power outages, T-Systems used to rely on its own diesel generators. But this is a thing from the past. By implementing a 'cross-cable' concept in the design of the fuel cell system, two fully independent power circuits are available all the time. In case the grid blacks out, the fuel cell takes over 100 per cent.

All images courtesy of Herman Gfaller, Silicon.de.

References:

Silicon.de: Bildergalerie: Brennstoffzelle im T-Systems-Rechenzentrum - August 30, 2007.

Silicon.de: Biogas fürs Rechenzentrum - T-Systems hat in seinem Rechenzentrum im Euro-Industriepark (EIP) München den Dauertest einer Brennstoffzelle gestartet - August 27, 2007.

Silicon.de: Geiz ist im Rechenzentrum geiler als Ökologie - August 17, 2007.

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

A round of climate change talks under the auspices of the United Nations Framework Convention on Climate Change (UNFCCC) concluded in Austria today with

A round of climate change talks under the auspices of the United Nations Framework Convention on Climate Change (UNFCCC) concluded in Austria today with  Scientists from Saint Petersburg have tested various materials for their ability to absorb hydrogen and

Scientists from Saint Petersburg have tested various materials for their ability to absorb hydrogen and  Brazil has

Brazil has

Open, convenient access to thorough information will drive new biomass science and technology out of the computer network and into our garages and homes. Scientists with the U.S. Sun Grant Initiative believe this, and today they

Open, convenient access to thorough information will drive new biomass science and technology out of the computer network and into our garages and homes. Scientists with the U.S. Sun Grant Initiative believe this, and today they  Brazil's state-run oil company Petrobras, a global and historic leader in biofuel development,

Brazil's state-run oil company Petrobras, a global and historic leader in biofuel development,

The Energy Crops Company has

The Energy Crops Company has  In a very important step towards the creation of a global carbohydrate economy, Syngenta has

In a very important step towards the creation of a global carbohydrate economy, Syngenta has

Cardiff scientists exploring the safe storage of hydrogen to power vehicles as an environmentally friendly alternative to petrol have

Cardiff scientists exploring the safe storage of hydrogen to power vehicles as an environmentally friendly alternative to petrol have

The U.S. Department of Energy (DOE) today

The U.S. Department of Energy (DOE) today  Biogas is rapidly becoming one of Europe's most important biofuels, with the sector scaling up to produce the alternative to natural gas on an industrial scale. Last year, thousands of plants produced an estimated 5.3 million tonnes of oil equivalent energy from biogas (

Biogas is rapidly becoming one of Europe's most important biofuels, with the sector scaling up to produce the alternative to natural gas on an industrial scale. Last year, thousands of plants produced an estimated 5.3 million tonnes of oil equivalent energy from biogas (

Radar Acquisitions Corp.

Radar Acquisitions Corp.  According to the chief of the United Nations'

According to the chief of the United Nations'

Saturday, September 01, 2007

First global satellite survey of gas flaring shows hidden costs of oil

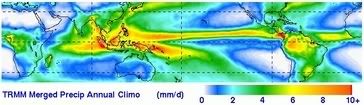

Gas flaring estimates, which were produced for sixty countries or areas around the world, show that global gas flaring has remained stable over the past twelve years, but remains large - in the range of 150 to 170 billion cubic meters (bcm).

Flaring or burning of gas is widely used to dispose of natural gas liberated during oil production and processing when this occurs in remote areas far from potential users, where there is often no infrastructure on site to make use of the gas. In recent years, however, renewed efforts are being made to eliminate flaring, such as re-injecting it into the ground to boost oil production, converting it into liquefied natural gas for shipment, transporting it to markets via pipelines, or using it on site for generation of electricity:

Since this is the first study of gas flaring using satellite observations, scientists warn that these preliminary results should be used with caution, as there still are several sources of error and uncertainty, including variations in flare efficiency, mis-identification of flares, non-continuous sampling, and environmental effects:

In any case the results are welcomed by the climate change and energy community.

According to the satellite observations, 22 countries have increased gas flaring over the past 12 years. These include: Azerbaijan, Chad, China, Equatorial Guinea, Ghana, Iraq, Kazakhstan, Kyrgyzstan, Mauritania, Myanmar, Oman, Philippines, Papua New Guinea, Qatar, Russia (excluding Khanty Mansiysk region), Saudi Arabia, South Africa, Sudan, Thailand, Turkmenistan, Uzbekistan, and Yemen.

On the other hand, the satellite observations show that 16 countries have decreased gas flaring from 1995 to 2006, including Algeria, Argentina, Bolivia, Cameroon, Chile, Egypt, India, Indonesia, Libya, Nigeria, North Sea, Norway, Peru, Syria, UAE and USA (offshore).

And nine countries have had largely stable gas flaring across those 12 years. These include Australia, Ecuador, Gabon, Iran, Kuwait, Malaysia, Khanty-Mansiysk (Russian Federation), Romania, and Trinidad.

The authors used low-light imaging data from the U.S. Air Force Defense Meteorological Satellite Program to assess the volumes of gas burned in flares, which are visible in observations of nighttime lights under cloud-free conditions (map at the beginning of this article, click to enlarge). Current and planned satellite sensors will continue to provide data suitable for estimating gas flaring volumes for decades to come. GGFR encourages on-site monitoring as well to help track changes in gas flaring volumes and to report progress in reducing flaring.

In 2002 the World Bank and the Government of Norway started the Global Gas Flaring Reduction (GGFR) initiative, which now has 12 country partners and 10 industrial partners, including the world’s largest petroleum companies. GGFR’s main goal is to bring all major stakeholders around the table so that they can together reduce the barriers to eliminate gas flaring to minimum levels. These main barriers include lack of an effective regulatory framework for associated gas utilization, lack of markets and lack of infrastructure to take the gas to those markets.

The GGFR partnership, managed and facilitated by a team at the World Bank in Washington, DC, includes the following partners: Algeria (Sonatrach), Angola, Cameroon, Canada (CIDA), Chad, Ecuador, Equatorial Guinea, France, Indonesia, Kazakhstan, Khanty-Mansijsysk (Russia), Nigeria, Norway, U.K. Foreign Commonwealth Office, the United States (DOE); BP, Chevron, ENI, ExxonMobil, Marathon Oil, Hydro, Shell, Statoil, TOTAL; OPEC Secretariat, and the World Bank.

References:

National Geophysical Data Center / Global Gas Flaring Reduction: A Twelve Year Record of National and Global Gas. Flaring Volumes Estimated Using Satellite Data [*.pdf], Final Report to the World Bank - May 30, 2007

National Geophysical Data Center: Gas Flaring Survey, global results and country results.

Article continues

posted by Biopact team at 8:15 PM 2 comments links to this post