Lusophone world and China join forces to produce biofuels in Mozambique

For development economists, Mozambique is one of Africa's brightest success stories. After a cruel civil war that lasted nearly two decades (1975-1992), the country organised general elections, took a careful approach to the 'structural adjustment' programs introduced by international institutions like the World Bank and the IMF, and, ensuring political and economic stability, steadily attracted foreign investments. The country's GNI has doubled in the past 5 years, and GDP growth was 7.7% last year (World Bank data).

For development economists, Mozambique is one of Africa's brightest success stories. After a cruel civil war that lasted nearly two decades (1975-1992), the country organised general elections, took a careful approach to the 'structural adjustment' programs introduced by international institutions like the World Bank and the IMF, and, ensuring political and economic stability, steadily attracted foreign investments. The country's GNI has doubled in the past 5 years, and GDP growth was 7.7% last year (World Bank data).Some observers have asked why the transition to peace and democracy took so much longer in Angola, that other former Portuguese colony mired in conflict. The answer: the presence of oil and diamonds. As is often the case in Africa, the black gold is a true curse and a barrier to development. Mozambique has more traditional assets, less prone to triggering resource wars, such as a large agricultural potential.

This potential is now being (re)discovered by the Lusophone world. And biofuels are the focus of the attention. Mozambique has several advantages which make it an interesting bioenergy producer: suitable agroclimatic and agro-ecological conditions for a wide range of energy crops, including sugar cane and tree crops; abundant arable land resources, and a largely rural population (amongst the poorest of the world) craving for employment and increased incomes.

Fuel prices have been increasing and put a serious brake on the country's development, which is why the Mozambican government itself is studying the biofuels opportunity. The Energy Ministry says recent increases (9.3% in April, another 3% this week) in prices of diesel, petrol, paraffin, aviation fuel and domestic gas are a result of increased import costs. The Mozambican government has even been forced to enter into negotiations with the International Monetary Fund (IMF) and the World Bank for an additional US$50 million in its foreign reserves to strengthen its capacity to import refined fuels. In search for an alternative, the Mozambican government has recently encouraged farmers to start growing biofuel crops such as jatropha. A real policy is not in place yet, but the Lusophone countries - Brazil, Portugal and China (via Macau) - are helping to craft one.

Biofuel 'super power'

Experts from the International Energy Agency estimate that Mozambique alone can produce nearly 7 Exajoules worth of liquid biofuels for exports, without threatening food supplies for its rapidly growing population or biodiversity and protected conservation areas. This amount is roughly equal to a production of 3 million barrels of oil equivalent per day (and given its renewability, this 'green reserve' lasts for decades). In order to actualise the potential, the country does need an influx of investments in agronomic knowledge and skills, logistical infrastructures and biofuel production plants. On all these fronts, the Lusophone world is offering assistance, either trilaterally or bilaterally, in purely private or in public-private ventures.

Sino-Brazilian cooperation

First of all, Brazil's EMBRAPA, the world's leading research organisation dealing with tropical agriculture, is assisting with analysing the biofuel production potential in collaboration with a Portuguese company that acquired 100,000 hectares of land in Mozambique. EMBRAPA already has established an Africa office in Accra, Ghana, from where it enters into cooperation agreements with African countries in the fields of agriculture and bioenergy (earlier post). The same organisation attracted interest from the All China Federation, the world's largest trade union organisation uniting 130 million members, which wants to collaborate on biofuels in Mozambique as well.

China has a growing presence in the country and in Southern Africa in general, mainly aimed at exploiting mineral resources it needs for its own development. But now the rising giant is looking at agriculture and biofuels, and has created a synergy with EMBRAPA: whereas the latter organisation provides agronomic expertise, China will invest in much needed infrastructures (road, rail, waterways) which must make it possible to bring products to market. The cooperation in Mozambique is part of China's US$5 billion investment strategy for Southern Africa. The Portuguese Millennium Bank, via its 'Conselho Comercial China-África', is to open large credit lines for Chinese companies starting infrastructure projects in Mozambique:

bioenergy :: biofuels :: energy :: sustainability :: ethanol :: biodiesel :: biomass :: energy security :: South-South :: South-North-South :: Mozambique ::

bioenergy :: biofuels :: energy :: sustainability :: ethanol :: biodiesel :: biomass :: energy security :: South-South :: South-North-South :: Mozambique :: Brazil with Portugal and Italy

Secondly, Portugal's Galp Energia today created a joint-venture with Brazil's Petrobras, aimed at producing 600,000 tons of second-generation biodiesel ('H-Bio') in Brazil, for exports to Portugal. But both companies are now studying to involve Mozambique (and Angola) in the effort, because feedstock production there can serve efforts to alleviate poverty and bring employment to small farmers. 400,000 to 800,000 hectares of suitable land have been identified there.

Likewise, Petrobras and Italy's state-owned oil company ENI, are collaborating on both ethanol and biodiesel production in Mozambique (earlier post). The Italian giant is increasing its presence in Africa in traditional oil production, most notably in Angola and Congo, where it is also looking at exploring the biofuels potential.

Win-win synergy

Mozambique stands to gain from such 'trilateral' approaches to development. It will be crucial to distribute the country's rapidly growing economic wealth amongst the general population. One way to do this is by modernising agriculture and by creating new markets like the bioenergy market.

Since biofuel production is labor intensive and draws upon imputs from farmers, the opportunity is the best there is to activate the rural populations. Foreign knowledge and technology is needed to help farmers increase productivity, since Mozambican peasants currently use their land very inefficiently (yields are extremely low because of a lack of the most basic inputs, such as fertilizers, good quality seeds and basic agronomic knowledge). By drawing on this expertise from outside, and because of much-needed investments in infrastructures (such as tertiary and secondary roads connecting the country-side to main roads), a positive synergy between food and fuel production can be created: increased farmers' incomes from biofuel feedstock production can be invested in more efficient food production, and vice-versa.

More information:

Jornal Mundo Lusíada: Banco Millennium financiará aporte chinês em Angola e Moçambique - May 15, 2007.

Jornal de Notícias: Galp investe 50 milhões na refinaria de Matosinhos - May 19, 2007.

Sunday Times (South Africa): Fuel price up in Mozambique - May 19, 2007.

Macau Hub: Estatal brasileira Embrapa vai investir em África nos países onde a China vai aplicar cinco mil milhões de dólares - May 7, 2007.

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

A team of University of Georgia (UGA) researchers has

A team of University of Georgia (UGA) researchers has  Scientists have observed the first evidence that the Southern Ocean’s ability to absorb carbon dioxide, the major greenhouse gas, has weakened by about 15 per cent per decade since 1981. The Southern Ocean normally cycles about 15% of the world's carbon dioxide, but can no longer keep up. Researchers had predicted this weakening would occur somewhere in the second half of this century, not this soon. The Southern Ocean's efficiency at cycling vast amounts of carbon dioxide is due to its cool waters.

Scientists have observed the first evidence that the Southern Ocean’s ability to absorb carbon dioxide, the major greenhouse gas, has weakened by about 15 per cent per decade since 1981. The Southern Ocean normally cycles about 15% of the world's carbon dioxide, but can no longer keep up. Researchers had predicted this weakening would occur somewhere in the second half of this century, not this soon. The Southern Ocean's efficiency at cycling vast amounts of carbon dioxide is due to its cool waters. Australia may take a place in the front line of the global biochemical industry thanks to a new

Australia may take a place in the front line of the global biochemical industry thanks to a new  The governor of the Reserve Bank of Zimbabwe has

The governor of the Reserve Bank of Zimbabwe has  In what is a major boost to Brazil's biodiesel industry, the president of state-owned company Petrobras Distribuidora (BR), Graça Foster, and the logistics executive director at mining giant

In what is a major boost to Brazil's biodiesel industry, the president of state-owned company Petrobras Distribuidora (BR), Graça Foster, and the logistics executive director at mining giant  A team of plant scientists and material chemists have for the first time successfully used nanotechnology to penetrate plant cell walls and simultaneously deliver a gene and a chemical that triggers its expression with controlled precision. Their breakthrough brings nanotechnology to plant biology and agricultural biotechnology, creating a powerful new tool for targeted deliveries of DNA and drugs into plant cells. Experts think this kind of confluence of biotech and nanotech will find many applications in the bioenergy and biofuels sector (see our

A team of plant scientists and material chemists have for the first time successfully used nanotechnology to penetrate plant cell walls and simultaneously deliver a gene and a chemical that triggers its expression with controlled precision. Their breakthrough brings nanotechnology to plant biology and agricultural biotechnology, creating a powerful new tool for targeted deliveries of DNA and drugs into plant cells. Experts think this kind of confluence of biotech and nanotech will find many applications in the bioenergy and biofuels sector (see our  As the use of biomass in large power plants becomes more common, a problem arises: what to do with the large amount of ash that results from burning the renewable energy source? In Europe and the US (database of

As the use of biomass in large power plants becomes more common, a problem arises: what to do with the large amount of ash that results from burning the renewable energy source? In Europe and the US (database of

Of all regions, the African continent has the largest

Of all regions, the African continent has the largest  At a seminar on ethanol technologies organised by São Paulo's Industry Federation (FIESP), Brazil's

At a seminar on ethanol technologies organised by São Paulo's Industry Federation (FIESP), Brazil's  Brazil is not only a success story when it comes to biofuels, it is also an example of how a smart series of policies and economic incentives can reduce tropical deforestation, while at the same time increasing biofuel production. Despite what some campaigners claim, Brazil's energy crops do not grow in tropical rainforest zones, and deforestation is not automatically fuelled by the expansion of these crops. Land-use change and deforestation resulting from agricultural production for food is not simply causally related to land-use changes from expanded energy cropping. For this reason, Brazil has been able to steadily increase its biofuels output, while at the same cutting deforestation rates by half, in less than 5 years. A major achievement of the left-wing government of President Luiz Inácio Lula da Silva that has been noted by climate scientists and policy makers alike.

Brazil is not only a success story when it comes to biofuels, it is also an example of how a smart series of policies and economic incentives can reduce tropical deforestation, while at the same time increasing biofuel production. Despite what some campaigners claim, Brazil's energy crops do not grow in tropical rainforest zones, and deforestation is not automatically fuelled by the expansion of these crops. Land-use change and deforestation resulting from agricultural production for food is not simply causally related to land-use changes from expanded energy cropping. For this reason, Brazil has been able to steadily increase its biofuels output, while at the same cutting deforestation rates by half, in less than 5 years. A major achievement of the left-wing government of President Luiz Inácio Lula da Silva that has been noted by climate scientists and policy makers alike. The EU has launched an ambitious project to study and implement bioenergy projects in the semi-arid and arid regions of Africa, aimed at bringing modern biofuels to local populations, as well as exporting green fuels to world markets. Dubbed

The EU has launched an ambitious project to study and implement bioenergy projects in the semi-arid and arid regions of Africa, aimed at bringing modern biofuels to local populations, as well as exporting green fuels to world markets. Dubbed

Agência Brasil

Agência Brasil  The government of South Africa is speeding up its plans to kickstart a biofuels industry that is set to benefit small farmers across the country. Once home to millions of displaced black South Africans, the former socalled 'Homelands' are expected to become the heart of the country's biofuels production.

The government of South Africa is speeding up its plans to kickstart a biofuels industry that is set to benefit small farmers across the country. Once home to millions of displaced black South Africans, the former socalled 'Homelands' are expected to become the heart of the country's biofuels production. More importantly to us, the technologies for clean coal can be applied to biomass, resulting in so-called 'Bio-Energy with Carbon Storage' (BECS) systems. BECS is the only radical carbon

More importantly to us, the technologies for clean coal can be applied to biomass, resulting in so-called 'Bio-Energy with Carbon Storage' (BECS) systems. BECS is the only radical carbon

A team of scientists at the University of Missouri-Columbia has discovered a way to create engineered minichromosomes in maize and attach genes to those minichromosomes. This discovery opens new possibilities for the development of crops that are multiply resistant to viruses, insects, fungi, bacteria and herbicides, for the development of proteins and metabolites that can be used to treat human illnesses, and for third generation biofuels (made from energy crops engineered in such a way that their properties are matched to the specificities of a given bioconversion process). The technique used to create engineered minichromosomes should be transferable to other plant species.

A team of scientists at the University of Missouri-Columbia has discovered a way to create engineered minichromosomes in maize and attach genes to those minichromosomes. This discovery opens new possibilities for the development of crops that are multiply resistant to viruses, insects, fungi, bacteria and herbicides, for the development of proteins and metabolites that can be used to treat human illnesses, and for third generation biofuels (made from energy crops engineered in such a way that their properties are matched to the specificities of a given bioconversion process). The technique used to create engineered minichromosomes should be transferable to other plant species.

Now suppose you could join the best aspects of both the biofuels and the hydrogen economy: use a liquid biofuel like ethanol in combination with a highly efficient fuel cell that powers an efficient motor. This would make for a very intersting concept, but would require a dedicated fuel cell that can handle biofuels. Luckily, a

Now suppose you could join the best aspects of both the biofuels and the hydrogen economy: use a liquid biofuel like ethanol in combination with a highly efficient fuel cell that powers an efficient motor. This would make for a very intersting concept, but would require a dedicated fuel cell that can handle biofuels. Luckily, a  A poll by audit, tax and advisory firm KPMG questioning 553 financial executives from oil and gas companies on the future of oil and biofuels, was recently released. The survey gives a snapshot of oil execs' attitudes to global warming, Peak Oil and the potential of renewable fuels. The fact that a majority of them considers climate change to be a 'natural weather cycle' is highly significant: it shows the oil industry will go against the scientific consensus in order to maintain its power position in the energy matrix of our world.

A poll by audit, tax and advisory firm KPMG questioning 553 financial executives from oil and gas companies on the future of oil and biofuels, was recently released. The survey gives a snapshot of oil execs' attitudes to global warming, Peak Oil and the potential of renewable fuels. The fact that a majority of them considers climate change to be a 'natural weather cycle' is highly significant: it shows the oil industry will go against the scientific consensus in order to maintain its power position in the energy matrix of our world.

A new study by the International Energy Agency's

A new study by the International Energy Agency's

Saturday, May 19, 2007

Model allows farmers to calculate carbon stored in soils and to sell carbon credits

One of the most straightforward and immediate ways to reduce atmospheric carbon dioxide and slow global warming is by storing carbon in an inert form in agricultural soils. But before farmers can sell the carbon credits derived from this practise they need to be able to verify that changing soil management has increased the soil organic carbon (SOC) in their fields.

Accuracy key

Researchers at Montana and Colorado State Universities now have evidence that an existing soil model can be used to accurately estimate carbon levels in soil under certain climate and land conditions. By using this model, farmers and landowners will be able to verify soil carbon change for carbon trading. The scientists report their findings [*abstract] on the reliability of the "Century soil model" in the May-June 2007 issue of Soil Science Society of America Journal.

The findings have importance for the development of tools that can measure carbon storage as part of a system of carbon negative biofuel production (see below). The Century model estimates soil organic carbon content and soil organic carbon change using soil texture, weather, and farm management information, says Ross Bricklemyer, lead author of the study.

Working together with farmers from Montana, researchers compared Century model estimates of soil carbon storage to field SOC measurements. Scientists measured carbon storage and soil texture in 10 paired fields under no-till and conventional-till management. They estimated the increase in carbon stored under no-tillage adoption as the difference between carbon levels in no-till and till fields. They then compared the soil carbon values predicted by the Century model to measured SOC and SOC rate of change.

The Century model accurately predicted SOC content and rate of carbon change, however, differences between measured soil texture data and state and county soil texture maps greatly influenced carbon storage estimates:

"The accuracy and scale of soil texture data highly influence the accuracy of Century model estimations of soil carbon," said Bricklemyer. "The model accurately estimated soil carbon content and the influence soil clay content had on the amount of carbon in the soil."

Although texture was important in determining SOC storage estimates, the effect of no-tillage management on the rate of carbon storage was not influenced by texture in this study. Some scientists have found that high clay content, or heavy soils, store carbon more rapidly under no-tillage management than soils with little clay content, others have found that clay content has no affect on carbon storage rates under no-tillage practice.

Bricklemyer says that because the effects of clay content on the rate of soil carbon under no-tillage change are not well understood by the research community, clay content information was not directly used by the Century model for carbon change calculations.

"This study also points out the importance of establishing benchmark monitoring sites, under actual farm conditions, where soil texture, soil carbon and other soil properties can be accurately measured and re-measured over time," said Bricklemyer. "Such a system, which currently doesn't exist in the U.S., would help us improve and validate estimates of carbon sequestration over time."

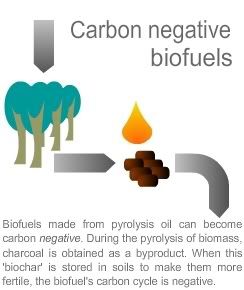

Carbon-negative biofuels

The Century soil model primarily looked at changes in soil organic carbon obtained from changing agricultural practises such as tilling versus no-tillage soil management. But there is a more radical way of using soils to store carbon and reduce greenhouse gas emissions by producing carbon negative biofuels.

The idea is to grow energy crops and to transform the biomass into two different products: liquid biofuels and charcoal. This can be done by a process called pyrolysis, which heats biomass in the absence of air, and which results in a syngas and biochar. The syngas can be transformed into liquid biofuels, whereas the char can be sequestered in soils.

This geosequestration technique not only stores carbon, but also increases the fertility of soils, on which new energy crops can then be grown. Such a fuel production system would result in carbon negative biofuels (earlier post). Under such a production scheme, farmers and biofuel producers would sacrifice part of the carbon from the crops that could be transformed into fuel by keeping it in a solid form (charcoal), but they would be able to sell the stored carbon on carbon markets.

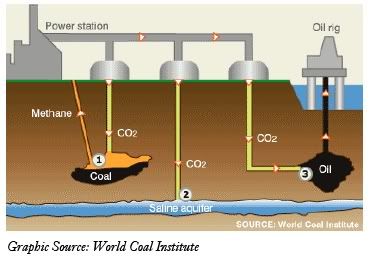

This concept is receiving more and more attention from the scientific community as the technique may be more readily and widely applicapble than other carbon storage techniques (such as 'carbon capture and storage' from large power plants, where the carbon from coal, natural gas or biomass would be captured and stored in depleted oil and gas fields or in other sites such as saline aquifers).

Moreover, storing carbon as charcoal in soils is a relatively simple technique that could be adopted rapidly by farmers in the developing world. In the tropics and subtropics, soils are often of low fertility and suffer under aluminum toxicity. Adding biochar could help in solving these problems. In fact, the technique was already known by communities in West Africa and the Amazon (where it is known as 'terra preta' or 'dark earth') who used it thousands of years ago to boost the fertility of their agricultural soils. Contemporary archaeologists and agronomists were baffled when they discovered these sites (earlier post).

The fact that the Century model was used by the researchers from the Montana and Colorado State Universities is an encouraging sign, indicating that work is being done on a scientific approach to the technique of retaining, storing and calculating carbon in soils. The Century model is already being used in the developing world by agronomists to teach farmers there how adapt their farming techniques so that soil organic carbon and fertility is retained. The fact that its accuracy is confirmed and that it becomes a practical tool for actually measuring changes in soil organic carbon levels as a result of farming practises, is promising for farmers in the South.

Image: the CENTURY model, which depicts four scenarios of possible future soil management, is being presented to members of the Conseil Rural in Fissel (Senegal) in order to promote discussion and evaluation of possible strategies to increase the amount of C in soil and biomass. Courtesy: P. Tschakert, Aridlands Newsletter.

More information:

Ross S. Bricklemyera, et al, Sensitivity of the Century Model to Scale-Related Soil Texture Variability, Soil Science Society of America Journal, 71, pp.784-792, published online 5 April 2007, DOI: 10.2136/sssaj2006.0168

Eurekalert: Before selling carbon credits, read this - May 18, 2007.

Biopact: Terra preta: how biofuels can become carbon-negative and save the planet - August 18, 2006

Biopact: Biochar soil sequestration and pyrolysis most climate-friendly way to use biomass for energy - April 26, 2007

Petra Tschakert, "Our carbon is gone; we have to bring it back!" Soil fertility management and social learning in Senegal's drylands, Aridlands Newsletter, No. 58, Winter 2005.

Article continues

posted by Biopact team at 3:53 PM 0 comments links to this post