TU Delft launches bionanoscience initiative

The Technical University of Delft, in the Netherlands, announces it is creating a new Bionanoscience department. Bionanotech concerns research at the meeting point of biology and nanotechnology and is as yet largely unexplored. It is expected to become one of the key scientific fields of the 21st century with potential applications in medicine, industrial biotechnology, biofuels, agriculture and many other fiels. Over the next decade, TU Delft is set to invest €10 million derived from strategic assets in the new Bionanoscience department, which will form part of the university’s Kavli Institute of Nanoscience. Last week, the Kavli Foundation also agreed to help support the initiative financially by donating US$5 million.

The Technical University of Delft, in the Netherlands, announces it is creating a new Bionanoscience department. Bionanotech concerns research at the meeting point of biology and nanotechnology and is as yet largely unexplored. It is expected to become one of the key scientific fields of the 21st century with potential applications in medicine, industrial biotechnology, biofuels, agriculture and many other fiels. Over the next decade, TU Delft is set to invest €10 million derived from strategic assets in the new Bionanoscience department, which will form part of the university’s Kavli Institute of Nanoscience. Last week, the Kavli Foundation also agreed to help support the initiative financially by donating US$5 million.Bionanoscience is the discipline where biology and nanoscience meet. The molecular building blocks of living cells are the focus of bionanoscience. The nanotechnology toolkit enables the precise depiction, study and control of biological molecules. This creates new insights into the fundamental workings of living cells. Furthermore, it is increasingly possible to use the elements of the cell, to the extent that – in a new disruptive field like synthetic biology – gene regulation systems, artificial biomolecules and nanoparticles can be developed and applied within the cells.

The incorporation of new biological building blocks in cells is highly promising for applications in, for instance, medical science and industrial biotechnology. This link to synthetic biology makes bionanoscience highly relevant in the quest to design dedicated bioconversion organisms for the efficient production of bioproducts and biofuels (more here).

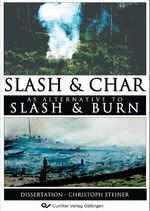

Science at the interface of nanotechnology and biotechnology is also seen as having a wide range of potential applications in agriculture and bioconversion: from nanoprocessing biomass for cellulosic ethanol, to the development of nano-catalysts and nano-channels for plant oil based fuels; from cellulose nano-crystals and fibre-enhanced bioplastics, to the design of micro-dosing technologies for nutrients, fertilisers and pesticides, to intelligent nano-bio-sensors and environmental sensors that improve agriculture and make it more sustainable (previous post).

TU Delft's Faculty of Applied Sciences’ new Bionanoscience department will explore the full spectrum from nanoscience to cell biology to synthetic biology, and as such will naturally and strategically complement the activities of the existing Nanoscience and Biotechnology departments.

Investment in biologically oriented fundamental research and its potential applications is of great strategic importance to TU Delft:

sustainability :: biomass :: bioenergy :: biofuels :: energy :: bioconversion :: synthetic biology :: biotechnology :: nanotechnology :: nanobiotech :: bionanoscience ::

sustainability :: biomass :: bioenergy :: biofuels :: energy :: bioconversion :: synthetic biology :: biotechnology :: nanotechnology :: nanobiotech :: bionanoscience :: This research field is new and has a bright future, and the research into individual cells is at the cutting edge of science and technology. Cell biology is becoming increasingly an engineering discipline: the traditional approach of the biologist is rapidly changing into that of the engineer. This is the motivation behind TU Delft’s strategic decision to add bionanoscience to its research portfolio and by doing so enhance its international position and profile.

In addition to TU Delft’s €10m contribution, last week the Kavli Foundation also decided that it is willing to donate US$5m to the bionanoscience initiative. The new department will work closely with the Nanoscience and Biotechnology departments and will ultimately be the same size as the existing departments in the Faculty of Applied Sciences. To this end, the next few years will see an intensive recruitment drive to attract about 15 top scientists to the department.

Initial steps have already been taken towards creating structural European cooperation: the prestigious European Molecular Biology Laboratory (EMBL) in Heidelberg has indicated its willingness to work together with TU Delft bionanoscientists. EMBL is a major potential partner, in particular in view of the EMBL’s expertise in the field of molecular cell biology. Further discussions on cooperation will be held with representatives from EMBL during a Kavli-EMBL workshop in Delft on 12 and 13 February.

References:

AlphaGalileo: TU Delft launches bionanoscience initiative - February 1, 2008.

Biopact: A quick look at nanotechnology in agriculture, food and bioenergy - December 13, 2006

Biopact: Scientists create first synthetic bacterial genome - importance for biofuels - January 25, 2008

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

India's Department of Biotechnology (DBT) at the Ministry of Science & Technology has

India's Department of Biotechnology (DBT) at the Ministry of Science & Technology has

Scientists at the Texas A&M University's chemical engineering department have genetically engineered the

Scientists at the Texas A&M University's chemical engineering department have genetically engineered the

Commercial tree planting is not a conventional type of business in Uganda but the New Forest Company (NFC), a UK-based firm, is signalling the growing attractiveness of the sector by announcing an investment that could reach $80 million over the coming years. The reforestation projects will supply woody biomass for power generation as well as timber for the construction industry. The concept shows that, contrary to the opinion of some bioenergy adversaries, biomass production is most often not based on deforestation, but rather on the opposite: reforestation and afforestation.

Commercial tree planting is not a conventional type of business in Uganda but the New Forest Company (NFC), a UK-based firm, is signalling the growing attractiveness of the sector by announcing an investment that could reach $80 million over the coming years. The reforestation projects will supply woody biomass for power generation as well as timber for the construction industry. The concept shows that, contrary to the opinion of some bioenergy adversaries, biomass production is most often not based on deforestation, but rather on the opposite: reforestation and afforestation. European energy giant

European energy giant  According to a new

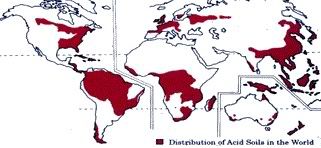

According to a new  A key book on the ancient soil improvement technique known as 'terra preta' has just been published. Compiled by Dr Christoph Steiner, who did extensive field work into the technique in Brazil,

A key book on the ancient soil improvement technique known as 'terra preta' has just been published. Compiled by Dr Christoph Steiner, who did extensive field work into the technique in Brazil,

This is why Dr Steiner's book is so important: it is a key addition to the growing body of scientific knowledge on terra preta and char amended soils. Based on his PhD thesis, defended before the Faculty of Biology, Chemistry and Geosciences at the University of Bayreuth in Germany, it provides data from actual field trials at several sites in Brazil. Cropping experiments on poor, highly weathered soils there showed that, in combination with fertilizers, char can boost crop yields significantly. Besides discussing the complex agronomy of these results in depth, Steiner also explores indigenous knowledge systems surrounding terra preta, looks at the economics of the system and offers suggestions for integrated applications.

This is why Dr Steiner's book is so important: it is a key addition to the growing body of scientific knowledge on terra preta and char amended soils. Based on his PhD thesis, defended before the Faculty of Biology, Chemistry and Geosciences at the University of Bayreuth in Germany, it provides data from actual field trials at several sites in Brazil. Cropping experiments on poor, highly weathered soils there showed that, in combination with fertilizers, char can boost crop yields significantly. Besides discussing the complex agronomy of these results in depth, Steiner also explores indigenous knowledge systems surrounding terra preta, looks at the economics of the system and offers suggestions for integrated applications. Netherlands-based Arcadis, an international consultancy, design and engineering company, today

Netherlands-based Arcadis, an international consultancy, design and engineering company, today  According to a Filipino- American scientist, bacteria in the rumen of a subspecies of water buffalo could help produce lignocellulosic biofuels. Dr. Fiorello Abenes, a professor emeritus of animal and veterinary sciences at CalPoly Pomona University in California, says the Carabao's rumen fluid contains organisms that can help transform rice stubble and straw and other types of non-food biomass into bioethanol.

According to a Filipino- American scientist, bacteria in the rumen of a subspecies of water buffalo could help produce lignocellulosic biofuels. Dr. Fiorello Abenes, a professor emeritus of animal and veterinary sciences at CalPoly Pomona University in California, says the Carabao's rumen fluid contains organisms that can help transform rice stubble and straw and other types of non-food biomass into bioethanol.

Saturday, February 02, 2008

Scientists unveil mechanical gas capture and storage technique based on nanovalves

The "molecular nanovalves" are based on the orderly crystal structure of a barium organotrisulfonate. The researchers developed a unique solid structure with this material that is able to convert from a series of open channels to a collection of air-tight chambers. The transition happens quickly and is controlled simply by heating the material to close the nanovalves, then adding water to the substance to re-open them and release the trapped gas.

Metal–organic frameworks have demonstrated functionality stemming from both robustness and pliancy and as such, offer promise for a broad range of new materials. The flexible aspect of some of these solids is intriguing for so-called 'smart' materials in that they could structurally respond to an external stimulus.

It is on the basis of such a stimulus-responsive framework that the gas capture device was developed: an open-channel metal–organic framework that, on dehydration, shifts structure to form closed pores in the solid. This occurs through multiple single-crystal-to-single-crystal transformations such that snapshots of the mechanism of solid-state conversion can be obtained.

Notably, the gas composing the atmosphere during dehydration becomes trapped in the closed pores. On rehydration, the pores open to release the trapped gas. For this reason, the new material represents a thermally robust and porous material that is capable of dynamically capturing and releasing gas in a controlled manner:

The researchers from the University of Calgary and the Steacie Institute for Molecular Sciences (National Research Council of Canada) say it represents a novel method of gas storage that could yield benefits for capturing, storing and transporting a range of important gases more safely and efficiently.

The paper includes video footage of the process taking place under a microscope, showing gas bubbles escaping from the crystals with the introduction of water.

The team intends to continue developing the nanovalve concept by trying to create similar structures using lighter chemicals such as sodium and lithium and structures that are capable of capturing the lightest and smallest of all gases - hydrogen and helium.

These materials could help push forward the development of hydrogen fuel cells and the creation of filters to catch and store gases like CO2 or hydrogen sulfide from industrial operations, says co-author David Cramb.

Capturing and storing (or transforming) greenhouse gases from industrial operations is becoming increasingly important for a transition towards a future low-carbon world. For biofuels in particular, capturing CO2 from the production process is important to improve the greenhouse gas balance of the fuel. The new gas capture technique also has potential applications in capturing and storing biomethane, a fuel obtained from the anaerobic digestion of organic waste.

References:

Brett D. Chandler, Gary D. Enright, Konstantin A. Udachin, Shane Pawsey, John A. Ripmeester, David T. Cramb & George K. H. Shimizu, "Mechanical gas capture and release in a network solid via multiple single-crystalline transformations", Nature Materials, advance online publication Published online: 20 January 2008, doi:10.1038/nmat2101.

University of Calgary: Rounding up gases, nano style - February 1, 2008.

Article continues

posted by Biopact team at 1:49 PM 0 comments links to this post