IBM finds recycling can cut solar cell manufacturing costs

IBM finds recycling can cut solar cell manufacturing costs

mongabay.com

October 30, 2007

IBM today announced a silicon wafer recycling system that could help ease the refined silicon shortage that has driven up production costs of solar energy panels.

The process allows efficient removal intellectual property from the wafer surface of discarded scrap semiconductors, “making these wafers available either for reuse in internal manufacturing calibration as ‘monitor wafers’ or for sale to the solar cell industry, which must meet a growing demand for the same silicon material to produce photovoltaic cells for solar panels,” according to the company. The system is currently in use at a Burlington, VT facility and in the process of being implemented at IBM’s East Fishkill, NY, semiconductor fabrication plant.

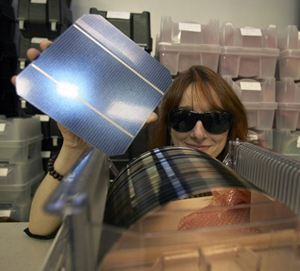

Shortage of silicon constains growth of solar panel industry: IBM has developed a process for repurposing scrap silicon wafers from its chip manufacturing operations for use in energy-producing solar panels. In this photo Michelle Bolz, an IBM manufacturing engineer, holds a solar panel above a crate of scrap silicon wafers ready to be recycled. IBM intends to provide details of the new process to the broader semiconductor manufacturing industry. |

“One of the challenges facing the solar industry is a severe shortage of silicon, which threatens to stall its rapid growth,” said Charles Bai, chief financial officer of ReneSola, one of China’s fastest growing solar energy companies. “This is why we have turned to reclaimed silicon materials sourced primarily from the semiconductor industry to supply the raw material our company needs to manufacture solar panels.”

IBM estimates that 3.3 percent of the 250,000 wafers produced globally are scrapped daily, adding up about 3 million discarded wafers per year. It says that because the wafers contain intellectual property, most are crushed and sent to landfills, or melted down and resold, instead of being re-used. IBM estimates that the new process could save enough silicon to generate 13.5 megawatts of solar energy. In 2006 global production of photovoltaics was 2,521 megawatts.

By using reclaimed silicon, IBM says that solar cell manufacturers can save between 30% and 90% of the energy that would have required using new silicon materials.

“These estimated energy savings translate into an overall reduction of the carbon footprint — the measure of the total amount of carbon dioxide (CO2) and other greenhouse gases emitted over the full life cycle of a product or service — for both the Semiconductor and Solar industries,” said IBM in a statement.