Butterfly biomimicry improves communications technology

Butterfly biomimicry improves communications technology

mongabay.com

December 11, 2006

A new DARPA-sponsored study says that biomimicry of butterfly wings can help researchers build complex photonic integrated circuits to improve communications technology.

“By replicating the complex micron- and nanometer-scale photonic structures that help give butterfly wings their color, researchers have demonstrated a new technique that uses biotemplates for fabricating nanoscale structures that could serve as optical waveguides, optical splitters and other building blocks of photonic integrated circuits,” stated a release from the Georgia Institute of Technology.

The news release detailing the research appears below.

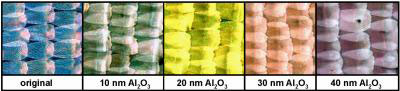

Wing Color Differences. An optical microscope image of coated butterfly wing scales show color differences related to the thickness of the deposited alumina. Image courtesy Zhong Lin Wang. |

Georgia Institute of Technology Research News: Butterfly wing scales provide template for complex photonic structures

By replicating the complex micron- and nanometer-scale photonic structures that help give butterfly wings their color, researchers have demonstrated a new technique that uses biotemplates for fabricating nanoscale structures that could serve as optical waveguides, optical splitters and other building blocks of photonic integrated circuits.

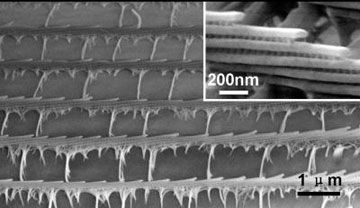

Wing Scale Structure. This scanning electron microscope image shows the structure on the surface of a butterfly wing scale. Credit: Image courtesy Zhong Lin Wang. |

Using a low-temperature atomic layer deposition (ALD) process, materials scientists at the Georgia Institute of Technology produced aluminum oxide (alumina) replicas of wing scales from a Morpho peleides butterfly, a bright blue insect native to the rain forests of Central and South America. The artificial wing scales faithfully replicated the physical features and optical properties of the natural wing scales that served as templates.

“We can never come close to the richness of the structures that nature can make,” said Zhong Lin Wang, Regents’ Professor in the Georgia Tech School of Materials Science and Engineering. “We want to utilize biology as a template for making new material and new structures. This process gives us a new way to fabricate photonic structures such as waveguides.”

The work has been reported in the American Chemical Society journal Nano Letters. The research was supported by the Defense Advanced Research Projects Agency (DARPA), the U.S. National Science Foundation (NSF) and the U.S. National Institutes of Health (NIH). The Day Butterfly Center at Callaway Gardens in Pine Mountain, Ga., provided the Morpho peleides butterfly specimen.

To create their artificial structures, Wang and colleagues Xudong Wang and Jingyun Huang deposited uniform layers of alumina onto butterfly wing scales one Angstrom at a time using the ALD process. (Huang was a visiting scientist from Zhejiang University, China). They were able to precisely control the thickness of the coating with the number of deposition cycles to which each wing scale template was subjected.

After the deposition, the coated scales were heated to 800 degrees Celsius to crystallize the alumina — and burn off the original butterfly wing scale. The resulting polycrystalline alumina was stronger than the original amorphous material deposited with the ALD process.

The artificial butterfly wing scale is a three-dimensional structure that retains the features of the original. That includes hollow tubular structures that split off at regular intervals, providing the potential for use as optical waveguides and optical splitters — and even as microfluidic or microreactor devices.

“Owing to the excellent uniformity of the alumina film, both the large-scale arrangement of the wing scales and the nanometer-scale periodic structures are perfectly preserved after this vigorous template removal process,” the authors wrote. “The alumina replicas of the wing scales exhibit the same shape, orientation, and distribution as their parent’ scales.”

Butterfly wing colors are produced by a combination of pigments and reflection from photonic structures. “If you examine the wing scale, you see all of the intricate micron-scale and nanometer-scale features that determine the optical properties,” Wang noted. “From a physical point of view, this is a very regular photonic structure with regular gaps that produce the bluish color.”

The artificial wing scales produced by the researchers also reflect bluish light, though the color is of slightly longer wavelength than that of the original butterfly. That’s because the chemical pigments that contribute to the original butterfly color are no longer present, and — Wang surmises — because the researchers had to dry the wing scales prior to deposition, which likely altered the size of their photonic structures.

Wang and his colleagues discovered that because the thickness of the alumina coating controlled the size and periodicity of the photonic structures, increasing the thickness shifted the reflected light toward the red portion of the spectrum. For instance, by increasing the coating thickness from 10 to 40 nanometers, the color reflected by the alumina wing scales shifted from the original blue to green, yellow, orange and eventually pink, Wang noted.

The complex nature of the structures would be impossible to create with any other process, he said. “This could provide a new way to make nanostructures that are replicated from biology,” he said. “It allows us to fabricate truly tubular, three-dimensional interconnected nanostructures in a one-step process.”

The atomic layer deposition process could potentially be used with other materials such as titanium oxide, and to replicate other biologically-inspired structures.

“As long as there is a void that the vapor phase can penetrate, an entire structure can be replicated using the ALD process,” Wang said. “Regardless of what the substrate is and what the three-dimensional shape is, you can control it to the Angstrom level.”

Next on the agenda may be the water strider, an insect that uses unique hydrophobic feet to skim gracefully across the surface of water. Wang would like to study the possibility of replicating the micron-scale structures of the insect’s feet, but he has found that obtaining samples may be difficult.

“I was trying to catch one of them, but they are very quick,” he admitted. “I almost fell into the water.”

This article is a modified news release from the Georgia Institute of Technology.