US ARS and Washington University team up to research biohydrogen, microbial fuel cells

Scientists from the U.S. Agricultural Research Service (ARS) and Washington University (WU) are collaborating on a three-year research project into biohydrogen and microbial fuel cells. They are screening electrochemically active and anaerobic bacteria that can convert sugars and organic waste directly into electricity or into hydrogen.

Scientists from the U.S. Agricultural Research Service (ARS) and Washington University (WU) are collaborating on a three-year research project into biohydrogen and microbial fuel cells. They are screening electrochemically active and anaerobic bacteria that can convert sugars and organic waste directly into electricity or into hydrogen.The initiative is aimed at making microbial fuel cells more efficient and practical. A bio-battery or microbial fuel cell (MFC) converts chemical energy, available in an organic substrate, directly into electricity. To achieve this, bacteria are used as a catalyst to convert substrate into electrons. The micro-organisms can convert a broad variety of organic compounds into CO2, water and energy. They use the produced energy to grow and to maintain their own metabolism. However, by using a MFC we can harvest a part of this microbial energy in the form of electricity.

Recent breakthroughs have made MFCs an exciting new research field, with many potential applications - from powering gadgets to space habitats to remote rural communities in the developing world (previous post, which delves deeper into MFC development). But the efficieny of these fuel cells can still be increased further.

According to Mike Cotta, who leads the ARS Fermentation Biotechnology Research Unit, Peoria, Ill., the project with WU arose from a mutual interest in developing sustainable methods of producing energy that could diminish U.S. reliance on crude oil. Cotta's team specializes in using bacteria, yeasts or other microorganisms inside bioreactors to do work, such as ferment grain sugars into fuel ethanol. At WU in St. Louis, Mo., assistant professor Lars Angenent is investigating MFCs systems that use mixtures of bacteria to treat organic wastewater and catalyze the release of electrons and protons, which then can be used to produce electricity or hydrogen fuel.

In September 2006, the researchers pooled their labs' resources and expertise to undertake a three-year cooperative project. One resource they'll share is the ARS Peoria-based Microbial Culture Collection, which houses about 87,000 accessions of freeze-dried microbes from around the world:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biohydrogen :: microbial fuel cell :: efficiency :: bacteria ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biohydrogen :: microbial fuel cell :: efficiency :: bacteria :: Using the collection's database information, the team is searching for microbes that "eat" biomass sugars (e.g., glucose and xylose from corn stover) and are electrochemically active. That means they can transfer electrons from fuel cell sugars without help from costly chemicals called mediators. The electrons, after traveling a circuit, combine with protons in a cathode chamber, forming hydrogen, which can be burned or converted into electricity.

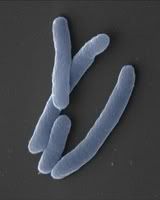

Bacteroides, commonly found in the human intestine, and Shewanella are among bacteria species used to start the process.

Hydrogen's appeal stems from its natural abundance and capacity to store and release energy in a nonpolluting manner. The challenge is commercially producing it from sources other than fossil fuels, which are in limited supply and nonrenewable. About 95 percent of U.S. hydrogen comes from petroleum or natural gas via a process called steam reforming.

Biobased membranes for fuel cells

In another development, a group of ARS scientists has found a way to replace the petroleum used in today's hydrogen fuel cell membranes with naturally occurring products.

In another development, a group of ARS scientists has found a way to replace the petroleum used in today's hydrogen fuel cell membranes with naturally occurring products.Justin Barone and colleagues in ARS' Environmental Management and Byproduct Utilization Laboratory in Beltsville, Md., have conducted preliminary studies which suggest the possibility of replacing the conventional petroleum-based main membrane in hydrogen fuel cells with biological products.

Hydrogen fuel cells have received a lot of attention as a possible energy conversion mechanism. The coming of what's being called a renewable "hydrogen economy" is being touted as a feasible alternative to current economic reliance on nonrenewable fossil fuels.

In the hydrogen economy, hydrogen fuel cells would replace internal combustion engines in vehicles, and hydrogen would replace gasoline. However, current hydrogen fuel cell technology is heavily dependent on petroleum to make both the fuel cells and the hydrogen fuel.

In biology, membranes surrounding cells routinely conduct hydrogen ions through the cell walls. Borrowing from this idea, Barone and his colleagues have focused their research on bio-based, nonpetroleum membranes made from naturally occurring products to conduct the hydrogen ions moving in and out of fuel cells.

Top picture: Shewanella bacterium. Credit: Hamilton College Microscopy & Imaging Facility.

Picture of the bio-based fuel cell membrane, credit: ARS.

References:

US ARS Fermentation Biotechnology Research: Research Project: Biological Hydrogen Production from Biomass Sugars by Electrochemically-Assisted Hydrogen Production in Microbial Fuel Cells, Project Number: 3620-41000-118-06, Start Date: Sep 05, 2006 - End Date: Jun 30, 2009.

ARS: Using Natural-Occurring Products To Build Hydrogen Fuel Cells - March 8, 2006.

Biopact: Microbial fuel cell development speeds up: from biopower in space to the developing world - September 30, 2007

--------------

--------------

U.S. oil prices and Brent crude rocketed to all-time highs again on a record-low dollar, tensions in the Middle East and worries over energy supply shortages ahead of the northern hemisphere's winter. Now even wealthy countries like South Korea are warning that the record prices will damage economic growth. In the developing world, the situation is outright catastrophic.

U.S. oil prices and Brent crude rocketed to all-time highs again on a record-low dollar, tensions in the Middle East and worries over energy supply shortages ahead of the northern hemisphere's winter. Now even wealthy countries like South Korea are warning that the record prices will damage economic growth. In the developing world, the situation is outright catastrophic.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home