Liquefied biogas?

First, a news story: Earth Biofuels announced that it has acquired Apollo LNG from its majority shareholder. Apollo LNG, now doing business as “Earth LNG,” owns a liquefied natural gas (LNG) processing facility in Topock, Arizona that currently produces over 80,000 gallons of transportation-grade LNG per day, and has a capacity of 86,000 gallons of LNG per day. LNG produced by the plant is sold primarily to municipal fleet customers located along the west coast of California.

Liquefied natural gas is produced by cryogenically transforming natural gas into a liquid state at a temperature of minus 163 degrees Celsius. The LNG is then transported to markets, either across oceans in specialized cryogenic supertankers or overland in dedicated tanker trucks. On arrival, it is used for electricity generation or as a transportation fuel, mainly by larger vehicles in municipal fleets that utilize a centralized fueling facility.

Now comes an important detail, expressed by Denis McLaughlin, the company's CEO: “We believe the LNG industry will begin to see new plants supplied by stranded natural gas from sources such as landfills and dairy farm waste manure. By liquefying this natural gas and getting it to transportation markets, LNG can further evolve into a renewable, clean burning fuel.”

Liquefied biogas from the developing world...

The 'stranded natural gas' in question here is in fact biogas - methane captured from biogenic sources. We were hesitant to suggest that biogas can indeed be liquefied and transported across the globe, just like its fossil counterpart, LNG. But now that a biofuel company is venturing into this idea, we feel more confident to explore it further. We take it South, to the developing world. The bioenergy resources in vast parts of this world can in fact be seen as 'stranded'. Turning these biomass resources into biogas, liquefying it and shipping it out may be a pipe-dream for now, but one worth exploring:

biomass :: bioenergy :: biofuels :: energy :: sustainability :: transport :: logistics :: developing world :: infrastructure :: airship ::LNG ::biogas ::

biomass :: bioenergy :: biofuels :: energy :: sustainability :: transport :: logistics :: developing world :: infrastructure :: airship ::LNG ::biogas :: The concept of 'stranded gas'

Let us first examine the concept of 'stranded gas' - a key term in the logistics and economics of natural gas. Despite being one of the most abundant energy sources on the planet, more than one-third of global natural gas reserves are classified as 'stranded'. The term refers to reserves that have been discovered, but have not been developed because they are uneconomic to deliver to market.

For almost a century, natural gas has been transported safely, reliably, and economically via pipeline, and pipelines were ideally suited to the supply and market conditions of the twentieth century, when large reservoirs of gas could be found in accessible locations that provided the stability and long-term security that pipeline projects demand. Now, in the 21st century, the vast majority of the large, easy, gas plays have been tapped, and attention is shifting to stranded reservoirs that were previously thought too small, too remote, or too geographically harsh to develop.

Now let us use this concept of 'stranded' reserves, and apply it to biofuels. The tropics and subtropics have a vast potential to produce renewable biomass, but often the logistical infrastructure to exploit this potential lacks. Vast zones in the South have no agricultural production because there are no roads, railroads, or waterways connecting them to markets. The prototypical example here may be the Democratic Republic of Congo, a country the size of Western Europe, with only 160 kilometres of paved roads... Because of this, only small villages can be found in the vast rural zones of these countries. They are cut off from the rest of the world and have to rely on some deplorable form of autarky to satisfy their own needs. Their biomass potential is, as it were, 'stranded'.

Overcoming infrastructural problems

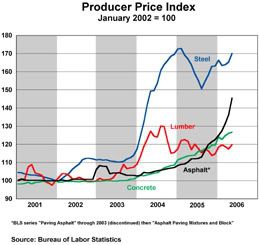

Building roads, railroads, canals and pipelines is a very expensive affair. And precisely because of rising energy prices it is becoming ever more expensive: over the past years, both asphalt, concrete and steel prices have risen to all-time highs (see graph), with the result that governments in the South are even more reluctant to build those infrastructures. The result is that rural communities remain cut off from markets, cannot sell any products, and ultimately sink deeper into poverty. The result: young people migrate from the country-side to the mega-cities and mega-slums, and the agricultural potential of the rural areas declines even further. A vicious circle.

Building roads, railroads, canals and pipelines is a very expensive affair. And precisely because of rising energy prices it is becoming ever more expensive: over the past years, both asphalt, concrete and steel prices have risen to all-time highs (see graph), with the result that governments in the South are even more reluctant to build those infrastructures. The result is that rural communities remain cut off from markets, cannot sell any products, and ultimately sink deeper into poverty. The result: young people migrate from the country-side to the mega-cities and mega-slums, and the agricultural potential of the rural areas declines even further. A vicious circle.Now if only this 'stranded' biofuel resource could be tapped in an efficient way, then villages that are cut off from the world market might prosper by becoming energy producers. Let us assume that governments in the South stick to a business as usual scenario and refuse to invest in transport infrastructures. Would there still be a way to bring the biofuels potential to market? Indeed, there might be.

Taking it to the skies

Agricultural logistics are highly complex and determine the economic viability of producing food in a specific region. Since biomass is an agricultural product, the same logistical challenges apply to it.

Biomass, in whatever form - wood, grass, grains, or residues -, is bulky. To get it to market in an economic way, it is often best densified or transformed locally into a fuel with a higher energy density. For example, wood chips from a forestry operation can be turned into fuel pellets, or into bio-oil in a nearby pyrolysis plant, and then transported to a refinery where it is turned into useable fuels. But such an option still requires roads, railroads or waterways.

Luckily, there is one form of bioenergy that can be moved out of its 'stranded' status without relying on road or rail transport. This form of energy is biogas, which can be literally airlifted.

The idea would be to create vast biogas producing zones in the inaccessible parts of developing countries, where vast unused land resources can be found, and where jobs and economic development are urgently needed. Biogas can be produced relatively easily and cheaply from a myriad of tropical feedstocks, with a major advantage being the fact that the high ambient temperatures in the (sub)tropics offer a considerable efficiency advantage (the fermentation of biomass into biogas becomes more efficient at higher temperatures - producers in 'cold' Europe spend a lot of primary energy on achieving these temperatures, whereas in the tropics ambient temperatures would suffice).

The gas would then be airlifted in dedicated biogas airships to terminals where it is purified, liquefied and shipped to world markets. The technologies to purify biogas to natural gas quality already exist (earlier post), and existing LNG terminals and infrastructures could be used.

Airship fantasies

In the 1970s, during the energy crisis, Royal Dutch Shell studied the feasibility of using airships to transport stranded gas to market. The research into this 'natural gas airship' pointed out that there are no real technical barriers, but that the longterm economics might be unfavorable. And indeed, when oil prices declined in the late 1980s, the plan was abandoned.

In the past few years, the idea has resurfaced. A small Bolivian company has taken the issue seriously and is looking into investing in such an airship to bring natural gas to markets that are difficult to reach (Bolivia is a mountaineous country). In a previous post, we tried to flip the idea on its head, by looking at how such an airship might be used to export 'stranded' biogas from rural communities to megacities where energy needs are increasing rapidly. With the potential to liquefy biogas, just like natural gas, the idea is not too far-fetched (whether it is economical is another matter alltogether).

Another, more serious presentation of the idea of natural gas airships was made during a recent conference called 'Airships to the Arctic', held in Canada for the third time already. NASA employee and airship historian Richard Van Treuren presented his view on the feasibility of an airship that can carry stranded (bio)gas to markets, at current energy prices.

His text is the best publicly available source on the idea, which is why we present parts of it here for future reference:

Over the years we have been looking at different motive power refinements. No one has actually built a true airship engine. We have worked on different things, external combustion, electric power, and human power. It got to the point where airplanes were being mass produced by so many different contractors that it seemed to make more sense to use airplane engines to push the gas bag around. (The first practical British anti-submarine airship was simply a wingless airplane hung under the gasbag. The US Navy just copied it, dubbing it the B-type air ship.) Zeppelin of course adapted marine motors for propulsion.

This “mitigated” the problem, as we are fond of saying around the space shuttle. This did allow us, over eight decades ago, to build hundreds of airships of great capability. One airship reached 22,000 feet of altitude. Another carried 30,000 pounds 4,200 miles without refueling. That was 88 years ago! 77 years ago we reached the pinnacle of the rigid airship art with the Graf Zeppelin. It was active for over 10 years, flew over a million miles, crisscrossed the Atlantic 144 times, and it was hit by lightning any number of times. It was shot at and hit any number of times. Exactly one insurance claim was filed in 10 years: bullet holes in the outer cover that occurred while they flew over a bad section of Latvia.

The secret to the Graf Zeppelin was not, as you would hear, good luck, but rather skill, proper management and one overwhelming advantage. It had a fuel that was about the same weight as air. It was a blended mix with a certain amount of hydrogen and a certain amount of propane. The upper part of the rigid air ship contained the hydrogen cells and the lower part were bags carrying fuel gas. The Graf Zeppelin lifted off from Tokyo, flew all the way across the Pacific and landed in Los Angeles with essentially the same static condition that it left. It was no accident that the Graf Zeppelin was the most successful airship of all time.

Though they built larger ones, the Hindenburg and the Graf Zeppelin II, even though they could carry more, they could not go further. The Graf Zeppelin was simply more efficient with its very high BTU quantity by weight fuel, much more so than the diesel fuel used in the later ships. This allowed the first actual attempt at building a cargo air ship. So what went wrong? Who dropped the ball? We always had the problem of propulsion, which we mitigated. However, once we adapted helium for lift and gasoline for fuel, we no longer had any control over our lift. Helium and gasoline is a marriage made in hell. The enormous weight of the motor, cars and gasoline, causes the whole bag to sag. Gasoline fuel is a problem for airship engineers and designers because the weight puts a strain on the structure, and disappears as you consume it.

Fuel gas automatically gives you a 25% advantage over liquid gasoline. C.P. Burges, the great guru who preceded Norm Meyer, had this all figured out. How they could have run on fuel gas and been much more efficient.

[...]

How do we get back to where they were 77 years ago with this magnificent, safe and efficient airship, the Graf Zeppelin? We will use modern materials that do not burn, we will update the electronics, and we will have GPS. It still will be kind of hard to get over this huge mental block whenever you say hydrogen in moving airships. Even hydrogen fuel guys do not want to talk to me, “Go away, we would rather not talk about airships.”

The 'killer' application: stranded gas

We need that poorly-called “killer” application. I believe we found it: Natural Gas. If we cannot figure out a way of moving natural gas, which is the best possible cargo for an airship because it is lighter than air, it is virtually free and can be sold for a huge profit, then I do not know what a killer application could be. It did not take too much time to find Canadian Superior Energy as one of many natural gas producers that had offshore holdings, in this case, Trinidad. How are they going to get the natural gas to market? Well, they will liquefy it and ship it on an LNG tanker. This is great if you happen to have a liquification plant, a port at both ends, and another plant to handle it, which you do not. They certainly do not want to build this infrastructure. Again, we have to look at the airship.

We can build a modern Graf Zeppelin that essentially is a fuel gas tanker. In the same way that the Graf Zeppelin had fuel gas in the bottom, we would carry fuel gas as the payload.

Just like the Bolivian company, Van Treuren looks at the Graf Zeppelin, which carried so-called 'blaugas' as fuel for its engines. In a modern gas cargo airship, helium would be used as the lifting medium, and biogas - which does not weigh more than air - would be both the cargo and the fuel for the craft's engines.

Commercial feasibility

Of course, it is highly unlikely that, at current natural gas prices, the idea of lifting biogas from inland to shore in airships, and then purifying and liquefying it to transport it in LNG tankers, is commercially viable. But some factors are in favor of it:

1. biogas can be produced in the vast inland zones of the tropics and the subtropics at prices much lower than those of biogas produced in Europe or North America; this is due to extremely low land and labor costs and very favorable agro-climatic conditions resulting in low cost biomass

2. biogas is a renewable, carbon-neutral fuel, and with projected price increases for carbon it will become ever more economical to use it on a large scale; carbon prices are expected to surge over the coming years, with an expected price range of €40-80 per metric ton, influencing electricity prices.

3. unlike natural gas, which has to be 'discovered', the production of biogas can be planned; one can point at a map, as it were, and decide to create a biogas production zone at a particular strategic location

4. the technologies to purify biogas to natural gas standards exist

5. prices of natural gas have increased sharply over the past years, with Europe now paying €250 per 1000 cubic meters and some projecting the price to go up to €300. At this level, liquefying natural gas and shipping it in tankers is feasible.

Seperately, all the elements of the above concept exist and have proved their viability. The question is whether they can be integrated into a novel, commercially viable transport and logistics concept that can unlock the immense bioenergy potential of the Global South.

More information:

Wood, J.E.R., The Shell Natural Gas Airship, and Other LTA Activities [*.pdf], Aerospace Developments, London, s.d.

Proceedings of Airships to the Arctic - Sustainable Northern Transportation [*.pdf], Third Symposium, University of Manitoba, held in Winnipeg, May 31 – June 2, 2005.

Biopact: Biogas distribution via a biogas-powered airship? - September 20, 2006

-------------------

-------------------

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

1 Comments:

Interesting but far-fetched idea. Biogas has a methane content of only 60-70%, far below that of NG (96%). So you're looking at an airship that would have to be considerably bigger than the NG-airships that are on the drawing board.

Moreover, you're not going to find that many lifuefaction facilities in Africa. In fact, there's only one, in Nigeria. Indonesia and Malaysia have several, but that's about it as far as the developing world is concerned.

Post a Comment

Links to this post:

Create a Link

<< Home