Beetle biomimicry could allow robots to climb vertical glass walls

mongabay.com

November 3, 2006

Researchers at Max Planck Institute for Metals Research are developing adhesives based on biomimicry of beetles’ feet.

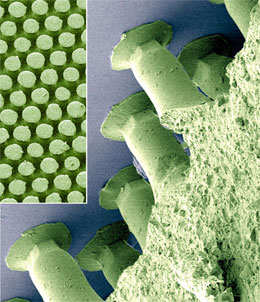

The design enables the materials to stick to smooth walls without any adhesives. The researchers say the technology, which uses microhairs “reminiscent of tiny mushrooms”, could someday allow robots to climb vertical glass walls and refrigerator magnets to be replaced by non-magnetic objects.

“In rigorous tests carried out by the Max Planck researchers with measuring instruments developed especially for the purpose, the artificial adhesive system gave an impressive performance and demonstrated many benefits. It lasts for hundreds of applications, does not leave any visible marks and can be thoroughly cleaned with soap and water,” reads a media release from the Max Planck Institute for Metals Research. “The researchers found that five square centimeters of the material can hold objects weighing up to one hundred grams on walls.”

Microscope image of the biomimetic surface structure of the new adhesive material. The material (green), which was inspired by the soles of insects’ feet sticks to the glass (blue). Image courtesy of the Max Planck Institute for Metals Research |

The researchers said smooth structures, like glass, are good bases for the adhesive material but that wallpaper and other rough surfaces do not work well.

“Insects also find it difficult to travel over slightly roughened surfaces – it’s a fundamental problem for adhesion mechanisms,” explained Project Leader Stanislav Gorb.

The researchers say the biomimetic adhesive work is still some years off from commercialization.

“There’s still a lot of work to be done by the Working Group. Something that functions smoothly in the laboratory is a long way away from large-scale production,” said Stanislav Gorb

Further information: PDF

Original work:

S. Gorb, M. Varenberg, A. Peressadko and J. Tuma. Biomimetic mushroom-shaped fibrillar adhesive microstructure. J. R. Soc. Interface 17 October 2006

K.A. Daltorio, S. Gorb, A. Peressadko, A. D. Horchler, R.E. Ritzmann and R.D. Quinn, A robot that climbs walls using micro-structured polymer feet. Proc. Int. Conf. Climbing and Walking Robots (CLAWAR), London, UK. 13-15. September 2005

Related articles

Shark biomimicry produces renewable energy system.

An Australian firm has developed a renewable tidal energy conversion system based on the highly efficient fin structure of shark, tuna, and mackerel. BioPower Systems, a renewable energy systems company based in Eveleigh, New South Wales, says that its bioSTREAM technology for converting tidal and marine current energy into electricity is modeled on biological species, such as shark and tuna, that use Thunniform-mode swimming propulsion.

Biomimetics, technology that mimics nature. Engineers, scientists, and business people are increasingly turning toward nature for design inspiration. The field of biomimetics, the application of methods and systems, found in nature, to engineering and technology, has spawned a number of innovations far superior to what the human mind alone could have devised. The reason is simple. Nature, through billions of years of trial and error, has produced effective solutions to innumerable complex real-world problems. The rigorous competition of natural selection means waste and efficiency are not tolerated in natural systems, unlike many of the technologies devised by humans. For example, gas-powered cars are only about 20 percent efficient, that is, only 20 percent of the thermal-energy content of the gasoline is converted into mechanical work.

Gecko feet inspire high-friction micro-fibers.

Inspired by the remarkable hairs that allow geckos to hang single-toed from sheer walls and scamper along ceilings, a team of researchers led by engineers at the University of California, Berkeley, has created an array of synthetic micro-fibers that uses very high friction to support loads on smooth surfaces.

This is a modified news release from the Max Planck Institute for Metals Research.