Torrefaction gives biomass a 20% energy boost, makes logistics far more efficient

Torrefaction, a process traditionally used to roast coffee beans, could give biomass a power boost, increasing the energy content of some leading energy crops and agricultural residues by up to 20 per cent, a study by engineers from the University of Leeds shows. Meanwhile, researchers in the Netherlands have produced an interesting case-study showing that, because of its significantly higher energy content, torrefied biomass can be imported from much further away, making long-distance trade feasible. The process makes the logistics of transporting and storing bulky biomass more efficient. Most interestingly, torrefaction also makes biomass more friable, making it far easier to grind. This opens the prospects of using existing coal pulverizers and of considerably lowering costs of co-firing biomass to generate electricity. With coal prices at all time highs, torrefaction technology might arrive just in time to make biomass even more attractive to energy companies looking into co-firing.

Interesting data on the feasibility of torrefaction might come from a first commercial biomass torrefaction plant that is already under construction in the Netherlands (earlier post).

The process

Originally developed in the 1930s in France, torrefaction of biomass has been derived from a process traditionally used to dry and roast coffee beans, which makes them brittle and gives them their distinctive flavour. The process involves gently roasting the beans up to temperatures of 280°C. In its new and bioenergy-related form, biomass is 'cooked' in an oxygen-free environment of anywhere between 200 and 300°C. Synonyms for the process are 'mild pyrolysis', 'wood cooking', 'high T drying', 'wood browning' or simply 'roasting'.

British researchers professor Jenny Jones and PhD student Toby Bridgeman examined the combustion behaviour of crops grown specifically for energy creation when put through this mild thermal process. In each case the crop was heated in a nitrogen gas atmosphere, to a maximum temperature of 300°C. Throughout the process they carried out chemical analysis to examine the way in which the crops decomposed. Afterwards they measured the mass and energy content of the new fuel.

The study, published in Elsevier's journal Fuel - The Science and Technology of Fuel and Energy, examined some major energy crops that grow in the UK: willow, canary grass and agricultural residue wheat straw. So what happened when these different types of biomass went through the torrefaction process and how did they behave at a range of temperatures when they were heated to create the energy-enhanced fuel?

Results showed that the treated materials needed less time and energy to heat to burning point, and also that they offered increased energy yields upon burning. Willow emerged as having the most favourable properties, in that it retained more of its mass in the torrefaction process and also performed best in terms of its energy yield. As an example, willow was shown to have an 86 per cent energy yield, compared with 77 per cent for wheat straw and 78 per cent for reed canary grass:

energy :: sustainability :: biomass :: bioenergy :: energy crops :: biomass residues :: energy density :: logistics :: torrefaction ::

energy :: sustainability :: biomass :: bioenergy :: energy crops :: biomass residues :: energy density :: logistics :: torrefaction ::

The researchers say the torrefaction process is increasingly seen as a desirable intermediate treatment for biomass because it creates a solid product which is easier to store, transport and mill than raw biomass, which has a relatively high moisture content.

Dutch research

Meanwhile in the Netherlands, which hosts some of the world's leading bioenergy analysts because the country has been looking at large-scale biomass imports from very early on, researchers found that torrefaction makes long-distance trade of biomass more feasible than it already is today.

The Energy Center of the Netherlands (ECN), which has already partnered to build a commercial-scale torrefaction plant, found that its integrated torrefaction-and-pelletisation process makes the long-distance trade and logistics of biomass more economical by anywhere between 30 to 70%. It ran comparisons of imported feedstocks from different areas. One example: sawdust located in South Africa that underwent the torrefaction and pelletisation process, could be transported to the Netherlands and co-fired there in existing coal-fired power plants, 70% more cheaply than the same sawdust merely pelletized using conventional processes.

In other research, also sponsored by the ECN, Dutch chemical engineer Mark Prins looks beyond co-firing and zooms in on gasification instead. He has shown that gasifying torrefied biomass is an efficient means of producing sustainable energy and that the gas produced can be used for the production of electricity, but also for fuels and/or chemicals.

Prins followed a thermodynamic approach to investigate how biomass could be gasified as efficiently as possible. He developed a concept which combines the two techniques: torrefaction and gasification. Roasting increases the calorific value of the biomass and decreases its humidity content. This considerably improves the properties of the biomass for gasification. At practical gasification temperatures between 900 and 1200°C, roasted biomass becomes less 'over-oxidised' than untreated biomass, which is favourable for the efficiency of the process. Efficient processes of this type need to be further developed if sustainable energy is to become a feasible option.

Prins' experimental research into the torrefaction of biomass was carried out in cooperation with the Netherlands Energy Research Foundation (ECN) and Shell Global Solutions, with the support of the Sustainable Energy Foundation (SDE). The process is more suitable for hardwood (e.g. beech and willow) and straw, than for softwood (e.g. larch), due to the composition of the hemi-cellulose fraction in the wood. During his research, Prins developed a model to describe the weight loss of the wood and he also analysed the products formed.

First plant under construction

Finally, it is worth noting that the ECN, sustainable energy consultancy Econcern and engineering and industrial investor Chemfo recently announced they have agreed to build a first commercial scale biomass torrefaction plant that will produce second generation biomass-based pellets for multiple applications: BO2pellets.

The BO2-technology is considered a key technology that enables a broad range of biomass streams, such as wood chips and agricultural residues, to be converted in an upgraded sustainable solid biofuel with a high energy density.

Torrefaction by means of the ECN process leads to an energy dense fuel pellet with a typical bulk density of 750 to 850 kg/m3, a net calorific value of 19 to 22 MJ/kg (as received) and a volumetric density of 14 to 18.5 GJ/m3 (bulk).

Typically, the torrefaction process has a thermal efficiency of 96% and the total production costs amount to €40-50 per ton of pellets. Importantly, with this process, the logistics costs can be reduced to 50%-66% of the costs involved for first generation wood pellets.

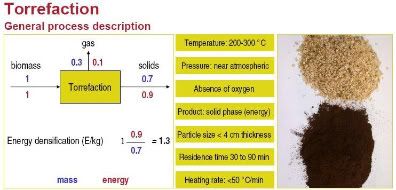

Schematic: general description of biomass torrefaction. Source: ECN.

References:

T.G. Bridgeman, J.M. Jones, I. Shield and P.T. Williams. "Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties", Fuel, Volume 87, Issue 6, Pages 605-1006 (May 2008), doi:10.1016/j.fuel.2007.05.041

University of Leeds: Energy crops take a roasting - 20 May 2008

Environmental Research Web: Coffee bean process could boost biomass power - June 25, 2008.

Biopact: Dutch partners agree to build commercial scale biomass torrefaction plant - Monday, November 12, 2007

Harold Boerrigter, Jaap Kiel, Patrick Bergman, Energy research Centre of the Netherlands (ECN), ECN Biomass, Coal & Environmental Research, "Biomass Pre-treatment by Torrefaction" [*.pdf], Third ThermalNET Meeting, 3-5 April 2006, Lille, France.

Energy research Centre of the Netherlands: Econcern, ECN and Chemfo agree to build commercial scale biomass torrefaction plant - November 8, 2007.

Patrick C.A. Bergman, Jacob H.A. Kiel, "Torrefaction for biomass upgrading" [*.pdf], ECN, Published at 14th European Biomass Conference & Exhibition, Paris, France, 17-21 October 2005

Patrick C.A. Bergman, "Combined torrefaction and pelletisation: The TOP process" [*.pdf], ECN Biomass, July 2005.

Biopact: Belgian-Dutch partnership to develop 5MW biocoal project - August 10, 2007

Biopact: Coal prices hit records too - time for biomass? - October 03, 2007

Interesting data on the feasibility of torrefaction might come from a first commercial biomass torrefaction plant that is already under construction in the Netherlands (earlier post).

The process

Originally developed in the 1930s in France, torrefaction of biomass has been derived from a process traditionally used to dry and roast coffee beans, which makes them brittle and gives them their distinctive flavour. The process involves gently roasting the beans up to temperatures of 280°C. In its new and bioenergy-related form, biomass is 'cooked' in an oxygen-free environment of anywhere between 200 and 300°C. Synonyms for the process are 'mild pyrolysis', 'wood cooking', 'high T drying', 'wood browning' or simply 'roasting'.

British researchers professor Jenny Jones and PhD student Toby Bridgeman examined the combustion behaviour of crops grown specifically for energy creation when put through this mild thermal process. In each case the crop was heated in a nitrogen gas atmosphere, to a maximum temperature of 300°C. Throughout the process they carried out chemical analysis to examine the way in which the crops decomposed. Afterwards they measured the mass and energy content of the new fuel.

The study, published in Elsevier's journal Fuel - The Science and Technology of Fuel and Energy, examined some major energy crops that grow in the UK: willow, canary grass and agricultural residue wheat straw. So what happened when these different types of biomass went through the torrefaction process and how did they behave at a range of temperatures when they were heated to create the energy-enhanced fuel?

Results showed that the treated materials needed less time and energy to heat to burning point, and also that they offered increased energy yields upon burning. Willow emerged as having the most favourable properties, in that it retained more of its mass in the torrefaction process and also performed best in terms of its energy yield. As an example, willow was shown to have an 86 per cent energy yield, compared with 77 per cent for wheat straw and 78 per cent for reed canary grass:

energy :: sustainability :: biomass :: bioenergy :: energy crops :: biomass residues :: energy density :: logistics :: torrefaction ::

energy :: sustainability :: biomass :: bioenergy :: energy crops :: biomass residues :: energy density :: logistics :: torrefaction :: The researchers say the torrefaction process is increasingly seen as a desirable intermediate treatment for biomass because it creates a solid product which is easier to store, transport and mill than raw biomass, which has a relatively high moisture content.

Raw biomass takes up a lot of space and has a low energy density which makes it costly - environmentally and economically - to transport. Plus you need more of it than say, coal, to produce energy efficiently. - Professor Jenny Jones

Torrefaction is not currently used in the UK in either the agricultural or the energy sectors. But our paper shows that it has a lot of benefits, besides those to do with fuel handling, so we feel it's definitely something we'd like to explore further. - PhD student Toby Bridgeman.Perhaps most exciting of all, the torrefaction process also made the fuels more friable, making it easier to grind. This might mean that milled biomass could be used in ordinary coal-fired power stations, burned alongside the pulverised coal, greening the fossil fuel's act.

In its normal state biomass is very hard to mill. After torrefaction it becomes much easier and raises the possibility of co-firing energy crops with coal using existing milling facilities. - PhD student Toby BridgemanBridgeman and Jones' research was supported by the Supergen Bioenergy Consortium, an initiative created by the Engineering and Physical Sciences Research Council as part of its commitment to funding research which will help the UK reach EU targets for the reduction of CO2 emissions and increased use of renewable energy.

Dutch research

Meanwhile in the Netherlands, which hosts some of the world's leading bioenergy analysts because the country has been looking at large-scale biomass imports from very early on, researchers found that torrefaction makes long-distance trade of biomass more feasible than it already is today.

The Energy Center of the Netherlands (ECN), which has already partnered to build a commercial-scale torrefaction plant, found that its integrated torrefaction-and-pelletisation process makes the long-distance trade and logistics of biomass more economical by anywhere between 30 to 70%. It ran comparisons of imported feedstocks from different areas. One example: sawdust located in South Africa that underwent the torrefaction and pelletisation process, could be transported to the Netherlands and co-fired there in existing coal-fired power plants, 70% more cheaply than the same sawdust merely pelletized using conventional processes.

In other research, also sponsored by the ECN, Dutch chemical engineer Mark Prins looks beyond co-firing and zooms in on gasification instead. He has shown that gasifying torrefied biomass is an efficient means of producing sustainable energy and that the gas produced can be used for the production of electricity, but also for fuels and/or chemicals.

Prins followed a thermodynamic approach to investigate how biomass could be gasified as efficiently as possible. He developed a concept which combines the two techniques: torrefaction and gasification. Roasting increases the calorific value of the biomass and decreases its humidity content. This considerably improves the properties of the biomass for gasification. At practical gasification temperatures between 900 and 1200°C, roasted biomass becomes less 'over-oxidised' than untreated biomass, which is favourable for the efficiency of the process. Efficient processes of this type need to be further developed if sustainable energy is to become a feasible option.

Prins' experimental research into the torrefaction of biomass was carried out in cooperation with the Netherlands Energy Research Foundation (ECN) and Shell Global Solutions, with the support of the Sustainable Energy Foundation (SDE). The process is more suitable for hardwood (e.g. beech and willow) and straw, than for softwood (e.g. larch), due to the composition of the hemi-cellulose fraction in the wood. During his research, Prins developed a model to describe the weight loss of the wood and he also analysed the products formed.

First plant under construction

Finally, it is worth noting that the ECN, sustainable energy consultancy Econcern and engineering and industrial investor Chemfo recently announced they have agreed to build a first commercial scale biomass torrefaction plant that will produce second generation biomass-based pellets for multiple applications: BO2pellets.

The BO2-technology is considered a key technology that enables a broad range of biomass streams, such as wood chips and agricultural residues, to be converted in an upgraded sustainable solid biofuel with a high energy density.

Torrefaction by means of the ECN process leads to an energy dense fuel pellet with a typical bulk density of 750 to 850 kg/m3, a net calorific value of 19 to 22 MJ/kg (as received) and a volumetric density of 14 to 18.5 GJ/m3 (bulk).

Typically, the torrefaction process has a thermal efficiency of 96% and the total production costs amount to €40-50 per ton of pellets. Importantly, with this process, the logistics costs can be reduced to 50%-66% of the costs involved for first generation wood pellets.

Schematic: general description of biomass torrefaction. Source: ECN.

References:

T.G. Bridgeman, J.M. Jones, I. Shield and P.T. Williams. "Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties", Fuel, Volume 87, Issue 6, Pages 605-1006 (May 2008), doi:10.1016/j.fuel.2007.05.041

University of Leeds: Energy crops take a roasting - 20 May 2008

Environmental Research Web: Coffee bean process could boost biomass power - June 25, 2008.

Biopact: Dutch partners agree to build commercial scale biomass torrefaction plant - Monday, November 12, 2007

Harold Boerrigter, Jaap Kiel, Patrick Bergman, Energy research Centre of the Netherlands (ECN), ECN Biomass, Coal & Environmental Research, "Biomass Pre-treatment by Torrefaction" [*.pdf], Third ThermalNET Meeting, 3-5 April 2006, Lille, France.

Energy research Centre of the Netherlands: Econcern, ECN and Chemfo agree to build commercial scale biomass torrefaction plant - November 8, 2007.

Patrick C.A. Bergman, Jacob H.A. Kiel, "Torrefaction for biomass upgrading" [*.pdf], ECN, Published at 14th European Biomass Conference & Exhibition, Paris, France, 17-21 October 2005

Patrick C.A. Bergman, "Combined torrefaction and pelletisation: The TOP process" [*.pdf], ECN Biomass, July 2005.

Biopact: Belgian-Dutch partnership to develop 5MW biocoal project - August 10, 2007

Biopact: Coal prices hit records too - time for biomass? - October 03, 2007

--------------

--------------

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home