The bioeconomy at work: Ford develops polyol foam based on soybeans

Earlier we reported about Toyota's initiative to produce bioplastics for car parts, about natural rubber flooring to be used in health care architecture and about the petroleum-free tire -- a range of bio-based product developments signaling the arrival of the bioeconomy. When such products will be mass-produced, the feedstock will likely come from the developing world, which is why developments in green chemistry are of interest to us. Now scientists at Ford's Research and Innovation Center are hailing a major breakthrough with soy-based polyurethane foams – the primary substance that makes up a vehicle's seat cushions, seat backs, armrests and head restraints.

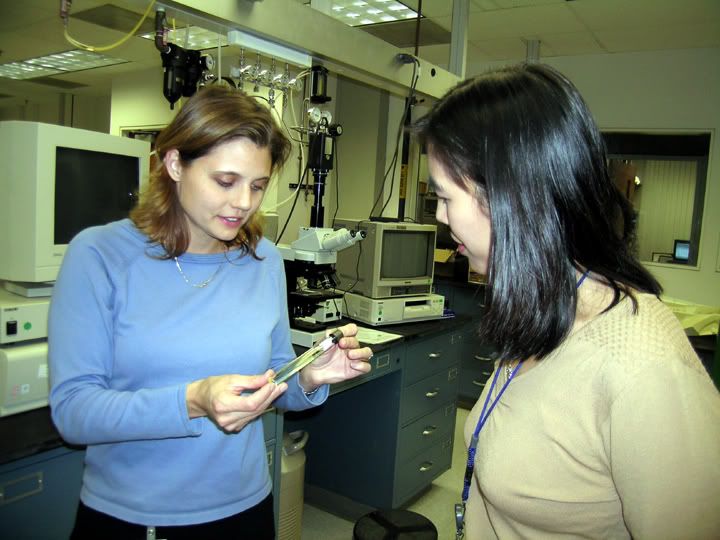

Earlier we reported about Toyota's initiative to produce bioplastics for car parts, about natural rubber flooring to be used in health care architecture and about the petroleum-free tire -- a range of bio-based product developments signaling the arrival of the bioeconomy. When such products will be mass-produced, the feedstock will likely come from the developing world, which is why developments in green chemistry are of interest to us. Now scientists at Ford's Research and Innovation Center are hailing a major breakthrough with soy-based polyurethane foams – the primary substance that makes up a vehicle's seat cushions, seat backs, armrests and head restraints.Picture: Dr. Cynthia Flanigan (left) shows colleague Dr. Ellen Lee the formula to a soy-based polyurethane used to make foam for seats and head restraints. This technology will someday replace petroleum-based foams and would help lessen the automaker's dependence on oil.

While many in the auto industry are experimenting with a 5% soy-based polyol – one of the many ingredients used to create the foam used in vehicles – Ford researchers have formulated the chemistry to replace a staggering 40% of the standard petroleum-based polyol with a soy-derived material. And they are doing it without compromising the durability, stiffness or performance of the foam.

"Five percent is relatively easy, a nice walk-before-you-run application, but there really isn't a solid business case to do it. We're talking about only 2% biomaterial for the total foam product. At 40%, which was formulated in our lab by our researchers, we have the ability to make a significant impact on the environment, while reducing our dependency on imported petroleum."Initial projections estimate that using a soy-based foam at high volumes could represent an annual material cost savings of as much as $26 million. As for the potential environmental benefit, according to the National Institute of Standards and Technology, soy polyols have only one-quarter the level of total environmental impact of petroleum-based ingredients:

Dr. Matthew Zaluzec, manager of Ford's Materials Research & Advanced Engineering Department.

biomass :: bioenergy :: biofuels :: energy :: sustainability :: green chemistry :: biopolymers :: polyol :: soybean :: bioeconomy ::

biomass :: bioenergy :: biofuels :: energy :: sustainability :: green chemistry :: biopolymers :: polyol :: soybean :: bioeconomy ::Ford first showcased its industry-leading work with soy foams in 2003 on the Model U concept, which featured soy-based seat cushions as well as a soy-based resin composite tailgate. Ford's research of possible applications for soybean products, however, actually dates back to the company's early years. The Model T, for example, once contained 60 pounds of soybeans in its paint and molded plastic parts.

"Soy is a very green, renewable resource," says Dr. Debbie Mielewski, technical leader for Ford's Materials Research & Advanced Engineering Department. "Using a soy-based foam gives us the opportunity to conserve natural resources and reduce our environmental footprint."

Most auto manufacturers today use a 100% petroleum-based polyol foam. Per year, the U.S. market for this material is 3 billion pounds; 9 billion pounds worldwide. According to Mielewski, an average of 30 pounds of petroleum-based foam is used in each vehicle produced, making a great case for auto manufacturers to consider and research other renewable, more environmentally friendly materials to produce the foam.

To protect its scientific advancements with soy-based foams, Ford has applied for two patents, one for high-content soy foam formulations and the other for a novel, low-odor process to synthesize polyols.

For some time, Ford researchers had been hitting a road block with the 40% soy-based foam because of its odd odor, reminiscent of vegetable oil. According to Formulation Chemist Christine Perry, that issue is now resolved thanks to a new synthesis method for soy polyol developed and tested at Ford's Research and Innovation Center. The new process utilizes room temperature UV light instead of high heat and catalysts to make the soy polyol. "Using high temperatures for the chemical reaction can cause numerous side products, which produce the rancid odor. It also requires a metal catalyst and more energy," says Perry. "With our breakthrough UV process, we have a simple reaction that is readily controlled by time of exposure, is inexpensive, and reduces the odor."

The actual foam is created by combining the 40/60 blend of soy- and petro-based polyol with an isocyanate cross-linking agent and nine other additives in precise combinations. "We have done a lot of work on the formulation," says Dr. Cynthia Flanigan, a technical specialist with Ford's Materials Research & Advanced Engineering. "Because none of the additives are independent of one another, when you make a change to one, it affects all the others." Extensive testing of high and low soy percentages revealed that a 40% to 50% soy substitution produced a product with properties most similar to the 100% petroleum-based polyol foam.

For Ford, the end product is a soy-based foam that exhibits the desired automotive properties for seating applications such as seat cushions, seat backs, armrests and head restraints. The foam's chemistry can also be altered as needed depending on factors such as the geometry of a part or required hardness of the foam.

Ford is working in conjunction with other organizations and suppliers to bring these innovative technologies to the mainstream as quickly as possible –several companies have already expressed interest in licensing them. Auto parts supplier Lear Corporation has conducted head restraint trials with the 40% soy foam, measuring how it performs with a variety of production head restraint tools used for Ford vehicles. Bayer MaterialScience LLC has made significant contributions to the foam's formulation development.

For the past three years, the project has received funding from the United Soybean Board (USB), a group of farmers/leaders that oversees investments in soy-based technologies. To date, Ford is the only auto manufacturer financially supported by the USB.

"We are certain that many of Ford's competitors are watching the company's efforts very closely with the idea of emulating any success Ford has with soy-based cushioning," says Todd Allen, chair of the USB's New Uses Committee. "We believe that when the first soy foams are introduced on Ford vehicles it will have a snowball effect on the usage of soy polyols by other industries such as agriculture equipment, recreational vehicles, office furniture cushioning and other automotive components."

-------------------

-------------------

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home