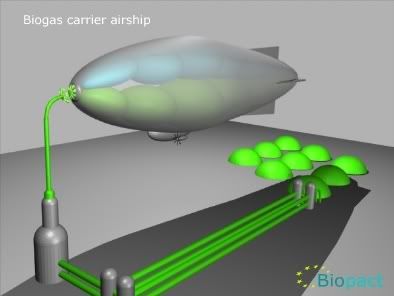

Biogas distribution via a biogas-powered airship?

In developing countries in the tropics and subtropics, distributing energy is extremely difficult because of a lack of adequate infrastructures. We are all familiar with images of trucks stuck on muddy roads during the rainy season, somewhere in a jungle in the South.

In developing countries in the tropics and subtropics, distributing energy is extremely difficult because of a lack of adequate infrastructures. We are all familiar with images of trucks stuck on muddy roads during the rainy season, somewhere in a jungle in the South.  Imagine driving a fuel or natural gas tank truck over those roads...

Imagine driving a fuel or natural gas tank truck over those roads...This infrastructural problem is a root cause of many other problems: rural areas remain in the dark and don't have energy access, farmers cannot export their agricultural products to cities or abroad, which keeps them even further in poverty; this poverty in turn results in huge internal migration patterns, where youngsters flee the countryside and enter the emerging mega-cities of the South (São Paulo, Mexico, Mumbai, Lagos, Kinshasa...), where they often end up in mega-slums.

Now a small Bolivian company called Reparando SA has come up with an innovative idea to overcome the problem. We want to take it even further, because the idea opens up a whole new perspective on the distribution of bioenergy, with the potential to 'airlift' many out of energy poverty and into becoming energy exporters (see below). But let us first look at Reparando's concept [cache]:

the idea is to deliver natural gas (NG) to remote areas by using an airship, rather than a pipeline or trucks. The company worked with Jesse Blenn, a US airship expert, on a preliminary design for a 150-meter airship capable of carrying about 35,000m³ of natural gas. The basic design is extensible up to a length of around 300m, which would result in a ship capable of carrying about 300,000m³. At 35,000 m³, the volume is approximately equivalent to the compressed gas carried by three natural gas tank trucks. But in many areas of Bolivia as in many parts of the developing world, roads are so bad that it could take a truck up to one week to go 500 miles.Now let us take this entire idea a few steps further. First, let us replace 'natural gas' with 'biogas' and 'diesel' with 'biodiesel'. We now have a biogas carrier airship that can overcome the infrastructural problems in the developing world. But instead of serving poor, rural communities in remote areas, we flip the idea on its head:

The ship as designed uses twelve internal inflatable gasbags: six for helium (the ship requires about 40% helium volume to lift the empty structure) and six for natural gas. The upper six bags hold the helium, the lower six the natural gas. This, Blenn points out, is very similar to the design of the system used by the Zeppelin Graf Zepplin I (LZ 127) in which the lower bags carried fuel gas which weighed nearly the same as air, and deflated as the fuel was used. The LZ 127 racked up nearly 1 million kilometers in flight.

With the natural gas on board, the ship has additional lift to carry diesel fuel, although the goal is to convert the airship engines to run primarily on natural gas. The diesel serves as ballast and backup. When running on natural gas, the four engines would consume about 3% of the natural gas payload in a round trip of 1,000 kilometers at a speed of 100 km/h. Discharge of the natural gas occurs through the mooring tower. The airship carries a normal operating pressure of about 35 mm water column, which will push the natural gas out within about 20 minutes through the twin NG valves. The twin nose engines supply the pressure and the 35,000 cubic meters of replacement internal air volume). (Four other natural gas engines provide propulsion.)

The mooring tower will include a proprietary automatic valve connection (purged with CO2), and a seal and bearing system which conduct the gas down to a duct where an auxiliary fan maintains the flow to storage. The reverse process handles the filling, but the inflation pressure is supplied from the tower base, not the engines. Blenn estimates that the airship could be built for around $US3 million (in South America). Airships, according to Blenn, have an operational life of about 10 years to first replacement of the outer fabric, and several decades for hard structures if refurbished.

biomass :: bioenergy :: sustainability :: rural :: developing world :: biogas :: biogas-to-liquids ::

biomass :: bioenergy :: sustainability :: rural :: developing world :: biogas :: biogas-to-liquids :: The concept then looks as follows:

Experts agree that remote communities in the rural areas of the tropics could potentially produce vast amounts of biomass, for which there is a world market. They are, as some have it, "the Saudi's of green energy". The only problem is that they lack the infrastructure to export these biofuels to the world market. It would be prohibitive to build a railroad or an asphalted road to a village in the heart of nowhere. But at the same time, this 'village in the heart of nowhere' is sitting on a resource that could make them potentially wealthy: favorable climatic conditions, vast stretches of very cheap and unused arable land, tropical crops that yield much more biomass than any crop in the North.

The situation really amounts to a catch-22: as long as there is no infrastructure, the resource will not be used. And as long as the resource is not used, no income comes from it, the community remains poor, and the State is not interested in building infrastructures serving the poor.

Now suppose a road was built to villages far away from the market. Immediately another hurdle would emerge: the raw biomass they produce is bulky and has a relatively low energy content, making it uneconomic to transport it in trucks over long distances. The trick is to densify it locally and then to transport it. Several companies are exactly working on this concept, by building modular bioconversion plants that can be placed near the producing community. Fast-pyrolisis plants would convert raw biomass into a bio-oil with a high energy content that would then be transported to more centralised refineries where the oil is processed into useable fuels (see earlier post). But this concept does not structurally solve the logistical problem in the South (bad roads, rainy season, no rail...).

Why this might be feasible

The option we are looking at with the airship offers another solution, potentially more feasible. Biomass could first be turned into biogas, instead of bio-oil. Several crops can be planted in a dedicated manner as biogas crops that yield high levels of methane in mono-feedstock anaerobic digester systems. Now this biogas is bulky too but compared to solid biomass, its energy content is much higher even though its density is much lower. This means: it can be airlifted, unlike raw biomass.

Producing biogas is rather straightforward and many rural communities in the developing world are already doing it. The technology is simple and can be scaled up easily. The idea is to create biomass-conversion centres around villages 'in the middle of nowhere', which would produce and store vast amounts of the renewable gas, that can be shipped out to market in the biogas carrier blimp. This concept provides a shortcut: no more waiting until a road arrives. Start exporting energy at once, and lift yourself out of poverty.

Biogas-to-liquids

Once the biogas arrives in the mega-cities of the South, it can be either used directly, by feeding it in the natural gas grid (after purification) and used for electricity generation or as biogas for cars. Alternatively it can be turned into a liquid fuel for cars - synthetic biofuel from biogas. This biogas-to-liquids technology already exists.

There's even the possibility of shipping the gas abroad to be sold on the world market (compressed natural gas carrier ships have meanwhile been approved - they can transport biogas too).

Obviously, the idea looks far-fetched and the beginning of a feasibility study by experts would quickly shed more light on it. But we presented it here, to illustrate some of the problems faced by the developing world, where biofuels can be produced competitively, but where infrastructural barriers are great.

Feel free to let us know what you think.

More information:

NGV global: Floating airship concept to deliver gas to remote locations [cache] - May 09, 2006

GreenCarCongress: Concept: Natural Gas Delivery Via a NG-Powered Airship -

14 May 2006

Original article: El Deber: Un “gasoducto” que viaja por el aire - March 2006

OilOnline: First CNG carrier ready for construction to ABS Class - September 19, 2006

Thomas Amon, Vitaliy Kryvoruchko, Barbara Amon, Werner Zollitsch, Erich Pötsch: Biogas production from maize and clover grass estimated with the methane energy value system - [*.pdf] Department of Sustainable Agricultural Systems, Division of Agricultural Engineering, University of Natural Resources and Applied Life Sciences, University of Vienna.

Pia Mähnert, Monika Heiermann, and Bernd Linke: Batch- and Semi-continuous Biogas Production from Different Grass Species,[*.pdf] Leibniz-Institute of Agricultural Engineering Potsdam-Bornim, Agricultural Engineering International: the CIGR Ejournal. Manuscript EE 05 010. Vol. VII. December, 2005.

Annimari Lehtomaki: Biogas production from energy crops and crop residues [*.pdf], Dissertation, Jyvaskyla Studies in Biological and Environmental Science (163), Faculty of Mathematics and Science, University of Jyvaskyla, 2006.

-------------------

-------------------

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home