New study shows stabilizing climate requires near-zero carbon emissions now - boosts case for carbon-negative bioenergy

This means carbon-negative bioenergy becomes the key technology, as it is the only energy system that allows societies to function normally while actively removing CO2 from the atmosphere. Carbon-negative bioenergy with its negative emissions is obtained by coupling carbon capture and storage (CCS) to bioenergy production - by either storing biogenic CO2 in geological formations or as biochar in soils.

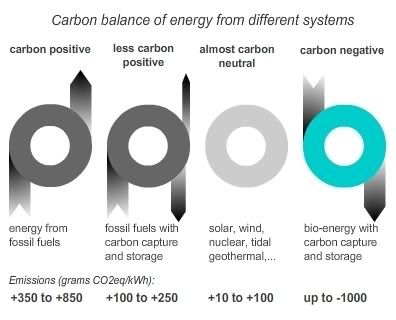

Ordinary renewables like wind, solar, or hydropower - which all add new CO2 to the atmosphere over their lifecycle - can play a role, but do not go far enough, especially given the enormity of the task of countering emissions from fossil fuels. Take photovoltaics: per kilowatthour of electricity produced, around 100 grams of CO2 equivalent is released over the entire lifecycle of the solar energy system. Wind power comes in at +30grams, as does biomass, while hydropower and nuclear add between 10 and 20 grams. Carbon-negative bioenergy on the contrary can yield up to -1000 grams (that is: minus a thousand grams per kWh). In short, the emissions generated by classic renewables and fossil fuels, must be counter-acted by carbon-negative bioenergy if we want to reach a level of near zero new emissions.

What if we were to discover tomorrow that a climate catastrophe was imminent if our planet warmed any further? To reduce emissions enough to avoid this catastrophe, we would have to cut them close to zero - and right away. - Ken Caldeira, Stanford University, Carnegie Institution, Department of Global EcologyIn the study, to be published in Geophysical Research Letters, climate scientists Ken Caldeira and Damon Matthews used an Earth system model at the Carnegie Institution's Department of Global Ecology to simulate the response of the Earth's climate to different levels of carbon dioxide emission over the next 500 years. The model, a sophisticated computer program developed at the University of Victoria, Canada, takes into account the flow of heat between the atmosphere and oceans, as well as other factors such as the uptake of carbon dioxide by land vegetation, in its calculations.

This is the first peer-reviewed study to investigate what level of carbon dioxide emission would be needed to prevent further warming of our planet.

Most scientific and policy discussions about avoiding climate change have centered on what emissions would be needed to stabilize greenhouse gases in the atmosphere. But stabilizing greenhouse gases does not equate to a stable climate. The scientists studied what emissions would be needed to stabilize climate in the foreseeable future.

They investigated how much climate changes as a result of each individual emission of carbon dioxide, and found that each increment of emission leads to another increment of warming. So, if we want to avoid additional warming, we need to avoid additional emissions. With emissions set to zero in the simulations, the level of carbon dioxide in the atmosphere slowly fell as carbon sinks such as the oceans and land vegetation absorbed the gas. Surprisingly, however, the model predicted that global temperatures would remain high for at least 500 years after carbon dioxide emissions ceased.

Just as an iron skillet will stay hot and keep cooking after the stove burner's turned off, heat held in the oceans will keep the climate warm even as the heating effect of greenhouse gases diminishes. Adding more greenhouse gases, even at a rate lower than today, would worsen the situation and the effects would persist for centuries.

Global carbon dioxide emissions and atmospheric carbon dioxide concentrations are both growing at record rates. Even if we could freeze emissions at today's levels, atmospheric carbon dioxide concentrations would continue to increase. If we could stabilize atmospheric carbon dioxide concentrations, which would require deep cuts in emissions, the Earth would continue heating up. Matthews and Caldeira found that to prevent the Earth from heating further, carbon dioxide emissions would, effectively, need to be eliminated:

energy :: sustainability :: biofuels :: biomass :: bioenergy :: renewables :: bio-energy with carbon capture :: carbon capture and storage :: geosequestration :: biochar :: carbon negative :: negative emissions :: climate change :: global warming ::

energy :: sustainability :: biofuels :: biomass :: bioenergy :: renewables :: bio-energy with carbon capture :: carbon capture and storage :: geosequestration :: biochar :: carbon negative :: negative emissions :: climate change :: global warming :: While eliminating carbon dioxide emissions may seem like a radical idea, Caldeira sees it as a feasible goal. It is just not that hard to solve the technological challenges, he says.

Ken Caldeira is a climate scientist in the Carnegie Institution Department of Global Ecology at Stanford University. Damon Matthews is a climate scientist in the Concordia University Department of Geography, Planning, and Environment in Montreal, Canada.

Going negative

In 2005, a group of scientists obtained a mandate from the G8 to study ways to drastically reduce and even eliminate carbon emissions on a global scale. This group, called the Abrupt Climate Change Strategy group (ACCS), found that carbon-negative bioenergy can be implemented on a global scale and would allow societies to function as normal. If implemented widely - replacing all fossil fueled power stations with biomass+CCS - we can even bring back atmospheric CO2 levels to pre-industrial levels by mid-century (2060), they found.

Carbon-negative bioenergy production is the only feasible geo-engineering type of intervention. Not only is it a very low risk strategy to eliminate emissions, it is commercially and economically manageable.

Negative emissions from bioenergy can be obtained both in electricity production as in biofuel production: in both cases, the biomass is decarbonised and the CO2 sequestered safely. Leaks from CO2 storage sites would not be problematic since the CO2 is biogenic in nature.

In power production, the biofuel is turned into hydrogen (a decarbonised fuel) in integrated gasification combined cycle (IGCC) power stations, after which the CO2 can be captured and stored. Other options exist, such as capturing emissions from existing power plants that have switched from coal to solid biomass or from natural gas to biogas. In biofuels for transport, the biomass is turned into hydrogen via gasification or biological fermentation, with the carbon dioxide again captured and sequestered.

Finally, negative emissions energy systems can be created by coupling bioenergy to biochar production. Part of the biomass is turned into an inert form of carbon (biochar or agrichar), which is then sequestered into soils (which boosts crop production). The rest of the energy is used for the production of power and heat. This way, energy can be generated while establishing a manageable carbon sink.

Only biomass-based systems can result in negative emissions energy that removes CO2 from the past and cleans up the atmosphere. In the event of "abrupt climate change" or when a radical transition to "zero emissions" is needed, which is the case according to Caldeira and Matthews, they are the key technology to achieve the goal.

References:

Matthews, H. D., and K. Caldeira (2008), "Stabilizing climate requires near-zero emissions", Geophysical Research Letters, doi:10.1029/2007GL032388, in press.

Eurekalerts: Stabilizing climate requires near-zero carbon emissions - February 14, 2008.

Scientific literature on negative emissions from biomass:

H. Audus and P. Freund, "Climate Change Mitigation by Biomass Gasificiation Combined with CO2 Capture and Storage", IEA Greenhouse Gas R&D Programme.

James S. Rhodesa and David W. Keithb, "Engineering economic analysis of biomass IGCC with carbon capture and storage", Biomass and Bioenergy, Volume 29, Issue 6, December 2005, Pages 440-450.

Noim Uddin and Leonardo Barreto, "Biomass-fired cogeneration systems with CO2 capture and storage", Renewable Energy, Volume 32, Issue 6, May 2007, Pages 1006-1019, doi:10.1016/j.renene.2006.04.009

Christian Azar, Kristian Lindgren, Eric Larson and Kenneth Möllersten, "Carbon Capture and Storage From Fossil Fuels and Biomass – Costs and Potential Role in Stabilizing the Atmosphere", Climatic Change, Volume 74, Numbers 1-3 / January, 2006, DOI 10.1007/s10584-005-3484-7

Further reading on negative emissions bioenergy and biofuels, and carbon capture techniques:

Peter Read and Jonathan Lermit, "Bio-Energy with Carbon Storage (BECS): a Sequential Decision Approach to the threat of Abrupt Climate Change", Energy, Volume 30, Issue 14, November 2005, Pages 2654-2671.

Stefan Grönkvist, Kenneth Möllersten, Kim Pingoud, "Equal Opportunity for Biomass in Greenhouse Gas Accounting of CO2 Capture and Storage: A Step Towards More Cost-Effective Climate Change Mitigation Regimes", Mitigation and Adaptation Strategies for Global Change, Volume 11, Numbers 5-6 / September, 2006, DOI 10.1007/s11027-006-9034-9

Biopact: Commission supports carbon capture & storage - negative emissions from bioenergy on the horizon - January 23, 2008

Biopact: The strange world of carbon-negative bioenergy: the more you drive your car, the more you tackle climate change - October 29, 2007

Biopact: "A closer look at the revolutionary coal+biomass-to-liquids with carbon storage project" - September 13, 2007

Biopact: New plastic-based, nano-engineered CO2 capturing membrane developed - September 19, 2007

Biopact: Plastic membrane to bring down cost of carbon capture - August 15, 2007

Biopact: Pre-combustion CO2 capture from biogas - the way forward? - March 31, 2007

Biopact: Towards carbon-negative biofuels: US DOE awards $66.7 million for large-scale CO2 capture and storage from ethanol plant - December 19, 2007

Biopact: Biochar and carbon-negative bioenergy: boosts crop yields, fights climate change and reduces deforestation - January 28, 2008

Article continues

--------------

--------------

The Andersons, Inc. and Marathon Oil Corporation today jointly announced ethanol production has begun at their 110-million gallon ethanol plant located in Greenville, Ohio. Along with the 110 million gallons of ethanol, the plant annually will produce 350,000 tons of distillers dried grains, an animal feed ingredient.

The Andersons, Inc. and Marathon Oil Corporation today jointly announced ethanol production has begun at their 110-million gallon ethanol plant located in Greenville, Ohio. Along with the 110 million gallons of ethanol, the plant annually will produce 350,000 tons of distillers dried grains, an animal feed ingredient.

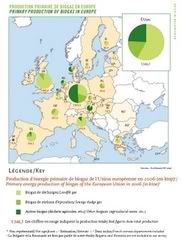

A growing number of remote sensing service companies is finding opportunities in the emerging bioenergy sector, by providing detailed data about the availability of biomass in a given region and the feasibility of harvesting it for commercial use. Similarly, several governments and international organisations are drawing on earth observation data that drive GIS-tools which allow policy makers and investors to assess biofuels potential, make investment and management decisions and allow for estimates of impacts on local economies, ecosystems and populations.

A growing number of remote sensing service companies is finding opportunities in the emerging bioenergy sector, by providing detailed data about the availability of biomass in a given region and the feasibility of harvesting it for commercial use. Similarly, several governments and international organisations are drawing on earth observation data that drive GIS-tools which allow policy makers and investors to assess biofuels potential, make investment and management decisions and allow for estimates of impacts on local economies, ecosystems and populations.

Friday, February 15, 2008

Syntec Biofuel achieves yield of 105 gallons of synthetic alcohol per ton of biomass

The Syntec B2A technology, initially developed at the University of British Columbia, is focused on second-generation cellulosic ethanol production via a process that parallels the low-pressure catalytic synthesis process used by methanol producers. The company has a specific focus on non-precious metal catalysts to synthesize specific alcohols (schematic, click to enlarge). High pressure catalytic synthesis requires substantial energy to operate and the risk associated with the high pressure is significant. Syntec Biofuels utilizes more energy efficient low pressure catalytic synthesis instead (previous post). Using this technology, it has now broken the 100 gallon per ton of biomass barrier for the first time.

Syntec’s synthetic biofuel technology uses any renewable waste biomass such as hard or soft wood, sawdust or bark, organic waste, agricultural waste (including sugar cane bagasse and corn stover), and switch-grass to produce syngas.

This syngas, comprised of carbon monoxide and hydrogen, is then scrubbed and passed through a fixed bed reactor containing the Syntec catalysts to produce ethanol, methanol and higher order alcohols. The Syntec technology can also produce alcohols from biogas ("biogas-to-liquids"), such as biogas sourced from anaerobic digestion of manure and effluent, landfill gas or stranded methane:

According to Syntec, the 105 gallon per ton yield marks a major milestone as it is equivalent to revenues in excess of $27 million per year for a 300 ton per day biomass processing facility.

In October 2007, Syntec calculated that the variable cost per gallon alcohol on then current yield (approximately 73 gallons per ton) was C$0.48 per gallon, which it expected to shrink to C$0.37 per gallon on reaching a targeted yield of 113 gallons per ton. Current dry mill production of corn ethanol yields approximately 100 gallons per ton of corn (2.8 gallons/bushel corn grain, 1 bushel = approximately 56 lbs).

Syntec is continuing to optimize its catalytic technology, and projects reaching the 113 gallon per ton yield this year.

References:

Syntec Biofuel: Syntec Biofuel achieves yield of 105 gallons of alcohol per ton of biomass - February 14, 2008.

Biopact: Syntec Biofuel acquires catalyst technology for biomass-to-liquids production - October 02, 2007

Article continues

posted by Biopact team at 5:51 PM 0 comments links to this post