StatoilHydro and India's ONGC team up for carbon capture & storage and CDM projects

The two companies have agreed to jointly screen possibilities for developing CCS and CDM projects within ONGC’s operations in India. The cooperation could result in CO2 emissions reduction projects as well as the promotion of energy efficiency and growing use of renewable energy under the mechanisms of the Kyoto Protocol.

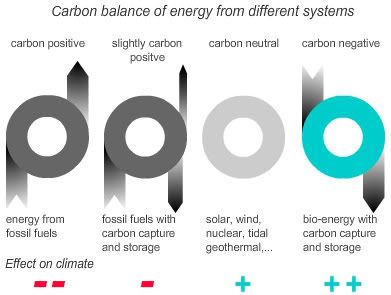

Biopact continues to track CCS developments (see references) because the technologies can be applied to bioenergy, in which case the most radically green energy system emerges: one that actively removes CO2 from the atmosphere to yield 'negative emissions'. When CCS is coupled to biomass-based electricity production or to biohydrogen production, each time consumers use the decarbonized energy, they would be cleaning up the atmosphere and be fighting climate change. Bioenergy coupled to CCS overcomes the senseless binary opposition often heard in clean energy debates, which pit fossil fuels with carbon capture versus renewables. "Bio-energy with carbon storage" (BECS) systems are both: renewable, and capturing carbon.

Nuclear power or renewables like wind, biomass and solar are called 'carbon neutral' because they do not add CO2 to the atmosphere, or only very small amounts over their lifecycle. But carbon-negative bioenergy goes much further: when CO2 from carbon-neutral bioenergy production is captured and then stored, a negative emissions energy system appears. This is so because during their growth, crops capture and store CO2 from the atmosphere. If, after extracting the energy from these energy crops, the greenhouse gas is geosequestered, the negative emissions balance is the result.

Nuclear power or renewables like wind, biomass and solar are called 'carbon neutral' because they do not add CO2 to the atmosphere, or only very small amounts over their lifecycle. But carbon-negative bioenergy goes much further: when CO2 from carbon-neutral bioenergy production is captured and then stored, a negative emissions energy system appears. This is so because during their growth, crops capture and store CO2 from the atmosphere. If, after extracting the energy from these energy crops, the greenhouse gas is geosequestered, the negative emissions balance is the result.Such radical BECS systems, using CCS technologies developed by the fossil fuel industry, can yield negative carbon emissions as large as minus 1000 grams per kWh of electricity. Ordinary renewables all result in net emissions (solar: +100gCO2eq/kWh, wind and non-BECS biomass: +30gCO2eq/kWh, nuclear: +15gCO2eq/kWh). In short, the difference between BECS and all other energy systems is very significant (graph, click to enlarge).

What is more, one of the major obstacles to the implementation of CCS projects when used on fossil fuels - the issue of CO2 leakage - would be absent in BECS systems, because the CO2 is biogenic in nature and would not result in net carbon emissions. Any leakage from BECS sequestration sites would be benign, in contrast to leakages from sequestered CO2 that originated from fossil fuels.

A Biopact member was recently interviewed by Mongabay, a leading environmental news organisation, about the potential and risks of BECS systems in developing countries. Laurens Rademakers explained biomass can be produced efficiently in many of these countries, some of who already have oil & gas infrastructures in place (which could coupled to CCS), and where suitable geosequestration sites are present. India would be one such country and could benefit greatly from BECS systems, as it is set to become the world's third largest carbon emitter in the mid term future.

For the time being, CCS is not included in any formal emissions reduction scheme - neither in the EU's plans and mechanisms nor in the Kyoto Protocol's CMD. But if CCS were to be included, the radical negative emissions BECS systems could be appearing first in developing countries, because they have a large and sustainable potential for the production of biomass:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon capture and storage :: carbon emissions :: carbon-neutral :: carbon-negative :: negative emissions :: bio-energy with carbon storage :: India ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon capture and storage :: carbon emissions :: carbon-neutral :: carbon-negative :: negative emissions :: bio-energy with carbon storage :: India :: The signing between StatoilHYdro took place at a special event organised by TERI (The Energy and Resources Institute) and the Norwegian Embassy prior to the Delhi Sustainable Development Summit (DSDS) in New Delhi, 7-9 February.

Norway’s Prime Minister Jens Stoltenberg and Nobel Peace Prize winner Dr Rajendra Pachauri were also present at the signing.

The agreement is an excellent start for developing environmental projects and technology transfers. India’s energy sector is growing fast and we’re excited to contribute with our CCS and CDM competence in the cooperation with ONGC. - Alexandra Bech Gjørv, Senior Vice President New Energy, StatoilHydroThe DSDS is an annual event that has matured into India’s most important gathering of international leaders concerned with global sustainable development. This year’s conference attracted the prime ministers of India, Norway, Denmark and Finland, as well as numerous ministers and government officials from several countries.

StatoilHydro has an agreement with ONGC that gives it access to exploration acreage off India, mostly in deep water. StatoilHydro will also enter block 98/2 in the KG basin on the Indian east coast with a 10% equity share. ONGC will receive technological support from StatoilHydro to increase the recovery of its Vasai East oil field. Furthermore, StatoilHydro will also provide ONGC with offshore operator know-how. Gas finds in the area The 98/2 block that is operated by ONGC is in the appraisal phase after a number of gas finds have been made in the block.

A CCS agreement between a European oil & gas company and a developing, emerging economy is not new. Recently, Total SA and Indonesia signed a similar deal. Indonesia is one of the leading candidates to implement CCS projects. It too has a large biofuel potential that could be coupled to carbon capture and storage (previous post).

References:

StatoilHydro: StatoilHydro and ONGC cooperate in India - February 6, 2008.

Biopact: Total and Indonesia sign a MOU on CO2 capture and storage: towards carbon negative bioenergy? - December 17, 2007

Mongabay: Carbon-negative bioenergy to cut global warming could drive deforestation:

An interview on BECS with Biopact's Laurens Rademakers - November 6, 2007

Scientific literature on negative emissions from biomass:

H. Audus and P. Freund, "Climate Change Mitigation by Biomass Gasificiation Combined with CO2 Capture and Storage", IEA Greenhouse Gas R&D Programme.

James S. Rhodesa and David W. Keithb, "Engineering economic analysis of biomass IGCC with carbon capture and storage", Biomass and Bioenergy, Volume 29, Issue 6, December 2005, Pages 440-450.

Noim Uddin and Leonardo Barreto, "Biomass-fired cogeneration systems with CO2 capture and storage", Renewable Energy, Volume 32, Issue 6, May 2007, Pages 1006-1019, doi:10.1016/j.renene.2006.04.009

Christian Azar, Kristian Lindgren, Eric Larson and Kenneth Möllersten, "Carbon Capture and Storage From Fossil Fuels and Biomass – Costs and Potential Role in Stabilizing the Atmosphere", Climatic Change, Volume 74, Numbers 1-3 / January, 2006, DOI 10.1007/s10584-005-3484-7

Further reading on negative emissions bioenergy and biofuels:

Peter Read and Jonathan Lermit, "Bio-Energy with Carbon Storage (BECS): a Sequential Decision Approach to the threat of Abrupt Climate Change", Energy, Volume 30, Issue 14, November 2005, Pages 2654-2671.

Stefan Grönkvist, Kenneth Möllersten, Kim Pingoud, "Equal Opportunity for Biomass in Greenhouse Gas Accounting of CO2 Capture and Storage: A Step Towards More Cost-Effective Climate Change Mitigation Regimes", Mitigation and Adaptation Strategies for Global Change, Volume 11, Numbers 5-6 / September, 2006, DOI 10.1007/s11027-006-9034-9

Biopact: Commission supports carbon capture & storage - negative emissions from bioenergy on the horizon - January 23, 2008

Biopact: The strange world of carbon-negative bioenergy: the more you drive your car, the more you tackle climate change - October 29, 2007

Biopact: "A closer look at the revolutionary coal+biomass-to-liquids with carbon storage project" - September 13, 2007

Biopact: New plastic-based, nano-engineered CO2 capturing membrane developed - September 19, 2007

Biopact: Plastic membrane to bring down cost of carbon capture - August 15, 2007

Biopact: Pre-combustion CO2 capture from biogas - the way forward? - March 31, 2007

Article continues

--------------

--------------

The Andersons, Inc. and Marathon Oil Corporation today jointly announced ethanol production has begun at their 110-million gallon ethanol plant located in Greenville, Ohio. Along with the 110 million gallons of ethanol, the plant annually will produce 350,000 tons of distillers dried grains, an animal feed ingredient.

The Andersons, Inc. and Marathon Oil Corporation today jointly announced ethanol production has begun at their 110-million gallon ethanol plant located in Greenville, Ohio. Along with the 110 million gallons of ethanol, the plant annually will produce 350,000 tons of distillers dried grains, an animal feed ingredient.

U.S. Energy Secretary Sam Bodman hinted last week the Bush administration might address cutting back the 54-cent-per-gallon import tariff on ethanol in its 2009 budget. But the budget has been sent to Congress and did not propose any changes to the tariff that is set to expire this year. Brazil is disappointed and says the tariff blocks U.S. consumers from using more efficient and environmentally friendly biofuels, such as ethanol based on sugarcane.

U.S. Energy Secretary Sam Bodman hinted last week the Bush administration might address cutting back the 54-cent-per-gallon import tariff on ethanol in its 2009 budget. But the budget has been sent to Congress and did not propose any changes to the tariff that is set to expire this year. Brazil is disappointed and says the tariff blocks U.S. consumers from using more efficient and environmentally friendly biofuels, such as ethanol based on sugarcane.

Wednesday, February 06, 2008

Ecologists find nitrogen pollution boosts plant growth in tropics by 20 percent - relevance for bioenergy

These findings could be significant to the bioenergy community, because they would imply that biochar based carbon-negative bioenergy systems ("slash-and-char") could be even more viable than estimated: their capacity to store atmospheric carbon dioxide into soils, via biochar obtained from regrown forests and energy crops, would be enhanced because of the increased plant growth resulting from atmospheric nitrogen fertilization.

Faster plant growth means the tropics will take in more carbon dioxide than previously thought, though long-term climate effects are unclear, the researchers say. Over the next century, nitrogen pollution is expected to steadily rise, with the most dramatic increases in rapidly developing tropical regions such as India, South America, Africa and Southeast Asia.

Major nitrogen sources are N fertilizer, applied to farmland to improve crop yield, which affects ecosystems downwind by seeping into runoff water and evaporating into the atmosphere. Industrial burning and forest clearing also pumps nitrogen into the air.

Surprisingly, tropical forests that were seasonally dry, located in mountainous regions or had regrown from slash-and-burn agriculture also responded to added nitrogen. Although these are not the tropical forests that typically come to mind, they collectively account for more than half of the world’s tropical forests.

Tropical grasslands responded too, but here the picture is more complex, as tropical grasslands are also limited by precipitation. The proportional increase in grassland productivity was constant across a rainfall gradient, but total growth increase was greatest at high levels of precipitation:

Scientists believed added nitrogen would have little effect in the tropics because plants there typically have ample nitrogen and are constrained by low levels of phosphorus. If one necessary plant nutrient is in short supply – in this case phosphorus – plant growth will be poor, even if other nutrients such as nitrogen are abundant. Experiments in the study added nitrogen at the high end of ambient nitrogen pollution to test the maximum potential response.

It is difficult to predict the long-term effects of nitrogen on global climate change. One factor will be the degree to which humans change natural ecosystems, for example by cutting down or burning the tropical forests. Further, climate change may determine whether these areas grow back as forests or if they are replaced by grasslands or deserts. It also is unknown how nitrogen will affect the fate of carbon once plants die and begin to decompose.

The scientists' work was supported by the National Science Foundation, the Department of Energy and a fellowship from the Kearney Foundation for Soil Science.

References:

LeBauer, David S., and Kathleen K. Treseder. 2008. "Nitrogen limitation of net primary productivity in terrestrial ecosystems is globally distributed", Ecology 89:371–379 (in press).

LeBauer, David: Nitrogen Limitation of Net Primary Productivity - research page at the UCI.

UC Irvine: Nitrogen pollution boosts plant growth in tropics by 20 percent - February 6, 2008.

Biopact: Biochar and carbon-negative bioenergy: boosts crop yields, fights climate change and reduces deforestation - January 28, 2008

Article continues

posted by Biopact team at 6:36 PM 0 comments links to this post