Researchers present new microbial pathways to bioenergy production

The American Society for Microbiology Press also released a new book titled Bioenergy, which in 30 chapters explores all kinds of microorganisms and conversion pathways to make renewable bioenergy out of a vast range of feedstocks. The book also compiles the latest information on microbial fuel cells and the potential of microbial electricity production, as well as numerous areas for new research in biofuel production.

Biodiesel from ethanol's CO2

A group of researchers is looking at alternative types of biomass as food for microorganisms to ferment into ethanol. The most attractive feedstocks are known as lignocellulosic biomass and include wood residues (including sawmill and paper mill discards), municipal paper waste, agricultural residues (including sugarcane bagasse) and dedicated energy crops (like switchgrass). The problem is, unlike sugar cane juice or corn, the sugars necessary for fermentation are trapped inside the lignocellulose.

Govind Nadathur and his colleagues at the University of Puerto Rico have been looking at unusual ecosystems and unusual organisms to find enzymes to help extract these sugars.

"Wood falls into the ocean. It disappears. What's eating this biomass? We found mollusks that eat the wood, with the help of bacteria in their stomachs that produce enzymes that break down the cellulose. We found something similar in termites," says Nadathur. They plan on using these enzymes as a key step in a closed, integrated system that would not only produce ethanol, but would also produce sugar, molasses, hibiscus flowers and biodiesel with a minimum of waste.

It all starts with sugar cane and hibiscus flowers, grown on local lands. These produce not only the obvious products such as refined sugar, molasses (which is used to make rum) and flowers, but also a large amount of waste in the form of biomass. Using the enzymes in their library, Nadathur and his colleagues could break down the biomass to sugars and ferment them to ethanol, trapping the carbon dioxide that is produced during fermentation. They then would feed the carbon dioxide to microalgae in ponds that would produce a polymer that could be refined into biodiesel or jet fuel. The spent microalgae could then be harvested and used as fertilizer for the next round of sugar cane and hibiscus, thereby closing the cycle.

There used to be a booming sugarcane industry in Puerto Rico, but in the mid-1990s it died. It could not survive economically. By creating a closed-loop system that utilizes the waste to create additional products and feeds back upon itself, suddenly growing sugar cane becomes economically feasible again. - Govind NadathurThey are currently working with a company called Sustainable Agrobiotech of Puerto Rico to build a pilot program which they hope to have running by early 2009. Should the pilot program prove successful, there is plenty of adjacent farmland to upscale.

Microbial biohydrogen: technical challenges

Another promising biofuel is hydrogen. Already many car manufacturers are producing hydrogen concept cars and pilot programs using hydrogen-powered buses already are gaining acceptance in Los Angeles, with Burbank announcing the addition of a hydrogen-powered bus to its fleet in the summer of 2008. As more buses come online, there will be a greater need for hydrogen. Unfortunately, current chemical manufacturing processes for hydrogen are not that efficient or use fossil fuels as a source.

Sergei Markov of Austin Peay State University has developed a prototype bioreactor that uses the purple bacterium Rubrivivax gelatinosus to produce enough hydrogen to power a small motor:

energy :: sustainability ::biomass :: bioenergy :: biofuels :: ethanol :: biodiesel :: biobutanol :: biohydrogen :: microbiology :: biochemistry :: synthetic biology ::

energy :: sustainability ::biomass :: bioenergy :: biofuels :: ethanol :: biodiesel :: biobutanol :: biohydrogen :: microbiology :: biochemistry :: synthetic biology :: Certain purple bacteria, which usually grow in the mud of various ponds and lakes, have the ability to convert water and carbon monoxide into hydrogen gas (note: only a certain set could use CO). The problem was how to effectively supply each bacterial cell in a liquid bacterial soup with gaseous carbon monoxide. - Sergei MarkovThe answer was attaching the bacteria to numerous tiny hollow fibers inside an artificial kidney cartridge. Water and gasses can freely diffuse through the fibers, but bacteria, due to their large size, cannot. The hydrogen gas from a small fifty milliliter "artificial kidney bioreactor" has been directly injected into fuel cells and has produced enough electricity to power small motors and lamps. The only drawback is that carbon monoxide is not readily available , but Markov says it can be easily produced from biomass using a specific thermochemical process. There are also other bacteria that produce carbon monoxide.

Hydrogen from water and sunlight

One researcher and her lab, though, are investigating what could perhaps be considered the holy grail of hydrogen production: pure hydrogen from only water and sunlight, with a little bacterial help. Using renewable energy like wind or solar power to power electrolysis is inefficient and costly. Microbial pathways may be more promising.

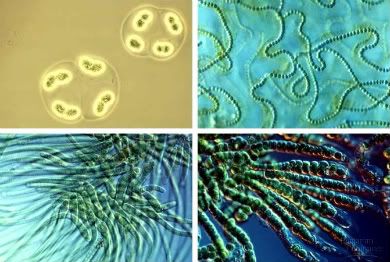

Pin Ching Maness of the National Renewable Energy Lab in Golden, Colorado, is researching cyanobacteria that harness the power of the sun to break the bonds in water, separating the hydrogen from the oxygen. There is a problem. One of the hydrogenase enzymes the cyanobacteria uses in this process is sensitive to O2, which makes sustained hydrogen production extremely difficult.

Luckily a certain purple bacterium use a similar hydrogenase, but one that is tolerant to O2. Maness and her colleagues have identified the genes that the purple bacterium uses to produce the tolerant hydrogenase. They have also identified the genes a particular model cyanobacterium uses to produce the sensitive hydrogenase and have knocked it out. They are currently in the process of cloning the genes for the tolerant enzyme into the model cyanobacterium. The next step is to verify that the genes have been successfully incorporated into the genome and are expressed. Over the next few years additional research will need to be done to ensure all the requirements are there for the construction of an active hydrogenase enzyme.

Methane from smoke stacks

Craig Venter for his part recently announced that his lab is working on the design of a bacterium that succeeds in utilizing the CO2 from coal plants and other industrial processes to make methane.

During his ocean expeditions which collected countless previously unknown microbes from the seas, Venter discovered several microorganisms that naturally metabolize CO2 and molecular hydrogen into CH4. He wants to boost their capacity to do so, and use CO2 captured from power plants to feed them (previous post).

Importantly, the microbes in question are not photosynthetic, which means they can be grown in reactiors that don't need a source of light. This is a major advantage over systems that use algae to capture CO2. These algae have to be grown in photobioreactors, which are expensive, or in open ponds, which limits their productivity and exposes them to competition with other algae.

References:

Eurekalert: Are microbes the answer to the energy crisis? - June 4, 2008.

ASM: New Text Highlights Role of Microorganisms in Alternative Energy Development - May 30, 2008.

Judy Wall, Caroline S. Harwood, Arnold L. Demain (eds.) Bioenergy, American Society for Microbiology Press, 2008, ISBN 978-1-55581-478-6, 454 pages.

Biopact: Venter speaks about synthetic life and alternative fuels - May 30, 2008

--------------

--------------

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

1 Comments:

Hello everyone,

This BioFuel seems to be taking off.

Algae fuel is very interesting.

Http://AlgaeFuel.ws

Post a Comment

Links to this post:

Create a Link

<< Home