Johnson Controls and Nexterra Energy form strategic alliance for biomass gasification projects

Johnson Controls, Inc., has formed a strategic alliance with Nexterra Energy Corp. to offer biomass gasification solutions to Johnson Controls customers, including higher education, health care, government facilities and industrial operations.

Johnson Controls, Inc., has formed a strategic alliance with Nexterra Energy Corp. to offer biomass gasification solutions to Johnson Controls customers, including higher education, health care, government facilities and industrial operations.Nexterra's patented gasification technology converts biomass into clean burning syngas that can be used to displace natural gas or fuel oil to generate heat and/or electricity. Under the strategic alliance agreement, the companies will jointly develop and implement biomass gasification projects that will enable customers to reduce energy costs, increase energy security, lower greenhouse gas emissions and become less reliant on fossil fuel by using locally sourced, renewable biomass fuel.

The gasification technology provides a clean, versatile and low cost means of converting wood and other solid fuels into syngas to produce heat and power at plant-scale applications. Nexterra has initially developed gasification systems to displace natural gas at sawmills, panelboard plants, pulp and paper mills, and institutional facilities using wood fuel. Future applications include systems that operate on coal and other low cost fuels.

The core of Nexterra’s technology is a fixed-bed, updraft gasifier (schematic, click to enlarge) whose operation can be described in four steps:

- Biomass, sized to 3 inches or less, is bottom-fed into the centre of a dome-shaped, refractory lined gasifier. The metering bin is designed to provide short term fuel storage and to deliver a steady rate of fuel to the gasifier. The metering bin out-feed augers have a variable speed drive that deposits fuel into a horizontal auger conveyor where it is transferred to a vertical conveyor. The vertical auger pushes fuel into the base of the fuel pile inside the gasifier. A constant fuel pile height is maintained in the gasifier over the entire operating range.

- Combustion air, steam and/or oxygen are introduced into the base of the fuel pile. Partial oxidation, pyrolysis and gasification occur at 1500 — 1800 °F, and the fuel is converted into “syngas” and non-combustible ash. As fuel enters the gasifier, it moves through progressive stages of drying, pyrolysis, gasification and reduction to ash. Combustion air (20 - 30% of stoichiometric), steam and/or oxygen are introduced through the inner and outer cone into the base of the fuel pile. The process is maintained by simultaneous control of combustion air and fuel feed rate. Combustion temperatures in the fuel pile are tightly controlled and kept below the ash melting temperatures to ensure that there is no formation of “clinker” and that the ash flows freely.

- The ash migrates to the base of the gasifier and is removed intermittently through an automated in-floor ash grate. As partially processed fuel passes to the outer cone, it is reduced to non-combustible ash. The ash migrates to the grate at the base of the gasifier where it is removed intermittently through a set of openings. The openings are normally covered by a rotating plate fabricated with the same pattern of openings. When hydraulically activated, the rotating plate aligns its openings with the fixed plate and the ash drops into two ash hoppers. Each ash hopper has two parallel augers to convey the ash to a collection conveyor and an enclosed ash bin.

- Syngas exits the gasifier at 500 — 700 °F. The syngas can then be combusted in a close coupled oxidizer with the resulting flue gas directed to heat recovery equipment such as boilers, thermal oil heaters, air-to-air heat exchangers and turbines. The syngas is thus used to produce useable heat, hot water, steam and/or electricity. Nexterra is also developing systems to directly fire syngas into industrial boilers, kilns, dryers and other equipment.

energy :: sustainability :: renewables :: bioenergy :: biofuels :: gasification :: syngas :: biomass ::

energy :: sustainability :: renewables :: bioenergy :: biofuels :: gasification :: syngas :: biomass :: Nexterra's capabilities add to a growing alliance of innovative energy technology partners that complement Johnson Control's existing renewable energy solutions and services.

Johnson Controls uses ingenious approaches to incorporate renewable technologies such as biomass, geothermal, solar and wind power with innovative energy efficiency strategies to provide customers long-term, sustainable solutions.

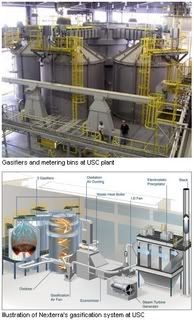

Most recently Johnson Controls partnered with Nexterra to provide a $20 million biomass gasification system for the University of South Carolina that is scheduled for start-up this fall (picture, click to enlarge). At peak capacity, the plant will generate 60,000 lbs/hr of steam which will be used to heat the campus, as well as 1.38 MW of electricity that will be sold to the grid. This gasification solution will now be replicated across a range of institutional and industrial markets throughout North America.

Most recently Johnson Controls partnered with Nexterra to provide a $20 million biomass gasification system for the University of South Carolina that is scheduled for start-up this fall (picture, click to enlarge). At peak capacity, the plant will generate 60,000 lbs/hr of steam which will be used to heat the campus, as well as 1.38 MW of electricity that will be sold to the grid. This gasification solution will now be replicated across a range of institutional and industrial markets throughout North America.Nexterra Energy is a developer and supplier of advanced biomass gasification systems that enable customers to self-generate clean, low cost heat and/or power using waste fuels "inside-the fence" at institutional and industrial facilities. Nexterra gasification systems provide a combination of attributes including design simplicity, reliability, versatility, ultra-low emissions, low cost and full automation.

References:

Johnson Controls: Johnson Controls and Nexterra Energy Form Strategic Alliance to Offer Biomass Gasification - October 11, 2007.

Nexterra: Nexterra Biomass Gasification System Nears Completion at Johnson Controls Cogeneration Plant for University of South Carolina - January 31, 2007.

--------------

--------------

Indian company Naturol Bioenergy Limited announced that it will soon start production from its biodiesel facility at Kakinada, in the state of Andhra Pradesh. The facility has an annual production capacity of 100,000 tons of biodiesel and 10,000 tons of pharmaceutical grade glycerin. The primary feedstock is crude palm oil, but the facility was designed to accomodate a variety of vegetable oil feedstocks.

Indian company Naturol Bioenergy Limited announced that it will soon start production from its biodiesel facility at Kakinada, in the state of Andhra Pradesh. The facility has an annual production capacity of 100,000 tons of biodiesel and 10,000 tons of pharmaceutical grade glycerin. The primary feedstock is crude palm oil, but the facility was designed to accomodate a variety of vegetable oil feedstocks.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home