CeBIT 2008: agro.Connect rlp creates an IT network for the agricultural domain

At this year’s CeBIT - the world's largest trade fair showcasing digital IT and telecom solutions -, Germany's Fraunhofer Institute for Experimentelles Software Engineering (IESE) and the University of Applied Sciences Bingen will jointly present state-of-the-art developments for simplifying business workflows in agriculture. The solution presented enables a farmer to create contract documents and transmit them to service providers and contract partners using the Internet. The agro.Connect rlp could cut administrative costs and time spent on bureaucratic tasks in agriculture.

At this year’s CeBIT - the world's largest trade fair showcasing digital IT and telecom solutions -, Germany's Fraunhofer Institute for Experimentelles Software Engineering (IESE) and the University of Applied Sciences Bingen will jointly present state-of-the-art developments for simplifying business workflows in agriculture. The solution presented enables a farmer to create contract documents and transmit them to service providers and contract partners using the Internet. The agro.Connect rlp could cut administrative costs and time spent on bureaucratic tasks in agriculture.Using agro.Connect rlp, it will be possible to include geographical data (aerial photographs, location and boundaries of cultivated areas) into agricultural documentation, administration, and business workflows, and exchange them. The crucial issue is the flexible usage of data that has been recorded once, and the avoidance of unnecessary multiple entries. To achieve this goal, the new technology dynamically combines geodata from the state government with user data from farm administration programs (schematic, click to enlarge).

The architecture is based on the principle of data sovereignty: Farm data worth protecting remain under the farmer’s control – a crucial prerequisite for the acceptance of this technology throughout the domain. agro.Connect rlp is being built on the basis of open standards (including XForms, ebXML, UBL, OGC, agroXML) and a service-oriented architecture (SOA); a prototype is being developed and a pilot project is taking place. First practical experiences have already been made; several software developing companies have already expressed their interest in agro.Connect rlp:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: agriculture :: administration :: IT :: e-business :: geodata :: Germany ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: agriculture :: administration :: IT :: e-business :: geodata :: Germany :: The project agro.Connect rlp is being carried out by Fraunhofer IESE and the Competence Center for Innovative Information Systems of the University of Applied Sciences Bingen together with the Service Center Rural Region Rheinhessen-Nahe-Hunsrück. It is funded by the Ministry for Economic Affairs, Transportation, Agriculture and Viniculture of the state of Rhineland-Palatinate. Other states will also be able to benefit from the developments initiated by the state of Rhineland-Palatinate.

Fraunhofer IESE is one of the worldwide leading research institutes in the area of software and systems development. A major portion of the products offered by its collaboration partners is defined by software. These products range from automotive and transportation systems to telecommunication and telematics equipment, from information systems and medical devices to software systems for the public sector.

Under the leadership of Prof. Dieter Rombach and Prof. Peter Liggesmeyer, the past decade has seen Fraunhofer IESE making major contributions to strengthening the emerging IT location Kaiserslautern. In the Fraunhofer Information and Communication Technology Group, it is cooperating with other Fraunhofer institutes on developing trend-setting key technologies for the future.

Fraunhofer IESE is one of 56 institutes of the Fraunhofer-Gesellschaft, Europe's leading fundamental science and research organisation.

References:

AlphaGalileo: CeBIT 2008:agro.Connect rlp Creates a Network for the Agricultural Domain - February 20, 2008.

agro.Connect rlp website.

CeBIT 2008.

Article continues

--------------

--------------

A bioethanol plant with a capacity of 150 thousand tons per annum is to be constructed in Kuybishev, in the Novosibirsk region. Construction is to begin in 2009 with investments into the project estimated at €200 million. A 'wet' method of production will be used to make, in addition to bioethanol, gluten, fodder yeast and carbon dioxide for industrial use. The complex was developed by the Solev consulting company.

A bioethanol plant with a capacity of 150 thousand tons per annum is to be constructed in Kuybishev, in the Novosibirsk region. Construction is to begin in 2009 with investments into the project estimated at €200 million. A 'wet' method of production will be used to make, in addition to bioethanol, gluten, fodder yeast and carbon dioxide for industrial use. The complex was developed by the Solev consulting company.

A global "Biofuels Biopact" between rich and poor countries can help alleviate poverty in the developing world while helping to solve the problems of global warming and energy security in the developed world, says a new

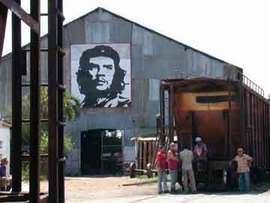

A global "Biofuels Biopact" between rich and poor countries can help alleviate poverty in the developing world while helping to solve the problems of global warming and energy security in the developed world, says a new  Cuba once was the world's largest sugar exporter, but since the collapse of the Soviet Union its output declined dramatically. Today, the island state is a shadow of its former self. Even though the emerging ethanol market holds major potential for the revival of Cuba's economy, Fidel Castro has spoken out against the fuel, claiming it endangers food security. This was mainly a rhetorical exercise, aimed at slamming the United States, because despite the criticism, Cuba has been quietly investing in its own ethanol infrastructure, striking deals with Venezuela and Nigeria.

Cuba once was the world's largest sugar exporter, but since the collapse of the Soviet Union its output declined dramatically. Today, the island state is a shadow of its former self. Even though the emerging ethanol market holds major potential for the revival of Cuba's economy, Fidel Castro has spoken out against the fuel, claiming it endangers food security. This was mainly a rhetorical exercise, aimed at slamming the United States, because despite the criticism, Cuba has been quietly investing in its own ethanol infrastructure, striking deals with Venezuela and Nigeria.

Wednesday, February 20, 2008

The bioeconomy at work: researchers develop remarkable self-healing biopolymer

The self-healing material is the fruit of research work conducted in the "Matière Molle et Chimie" Laboratory, a mixed research unit between the CNRS and ESPCI (Ecole Supérieure de Physique et de Chimie Industrielles) run by Professor Ludwik Leibler, a former colleague of Pierre Gilles de Gennes, 1991 Physics Nobel Prize.

The French researchers show that mass production of the rubber is near: they are already making kilogramme quantities in their Paris laboratories. Better still, the process is almost completely green, and could be entirely so with a few adjustments: an abundant renewable feedstock is used in a 'green chemistry' approach. The self-healing artificial rubber could have applications in anything from adhesives to self-repairing toys, shoes, gloves and bicycle tyres.

How it works

Conventional rubber is made of a single, continuous, stretchy molecule, held together with strong chemical links called covalent bonds. Once these bonds are cut by a break in the material the rubber can not be reassembled.

Leibler's approach was to use small molecular groups instead: the fatty acids from vegetable oil. Reacting these molecules with urea in a two-step process stuck nitrogen-containing chemical groups (amides and imidazolidones) onto the ends of the fatty acids. The fatty acids link to each other using hydrogen bonds — a strong attractive force between hydrogen and another atom, and the bond responsible for holding water molecules to each other.

The resulting molecular system is very non-uniform: some acids have three protruding groups and some have two. This means that the compound can't crystallize into a hard, shatterable material. Instead it can be stretched to five times its original size and then return to normal, albeit slower than an elastic band would — it takes around a minute.

If rubber is cut, the end groups on the acids become exposed, and the hydrogen bonds to neighbouring groups are broken. It is in the amide group's nature to seek out a partner to link up to, and this happens when the cut surfaces are brought back in contact — the hydrogen bonds can form again. The longer the cut ends are held together, the more of these partnerships are made, and the more completely healed the rubber is.

A freshly cut sample can heal enough that the re-stuck rubber can be stretched to twice its size again after just 15 minutes. The system isn't perfect yet — healed rubber that hasn't been left long enough will break again at the original 'wound' site. The broken rubbers will stick only to the other broken piece, and the rubber doesn’t have to be mended immediately — it can still efficiently reform up to 18 hours after being severed.

Other self-healing materials exist, but their bonds knit back together only when heated or a strong force is applied. Leibler’s material works at room temperature, and just requires the two broken bits to be held together gently.

New materials like this one are based on the concept of supramolecular chemistry, a promising branch of chemistry that offers a major improvement potential for everyday applications. From this technique, we can expect materials like ultra-tough bio-based bitumen laid at 140°C instead of 180°C, easily-molded bioplastics with superior mechanical strength and chemical stability, hotmelt glues from vegetable origin, or indeed, biobased self-healing rubber.

Supramolecular chemistry

For over two centuries traditional molecular chemistry has focused on transforming matter by creating permanent bonds linking up atoms within molecules. Polymer chemistry, derived from this traditional chemistry, has developed considerably in the last century, the objective being to produce large molecular chains that combine sturdiness with light weight.

Supramolecular chemistry – a scientific field that has come to the fore in recent years in particular thanks to the Chemistry Nobel Prize presented to Jean-Marie Lehn, Donald Cram and Charles Pedersen in 1987 – consists in building complex assemblies of molecules joined by non-permanent or "reversible" bonds; these assemblies of molecules with a "reversible" structure are called "supramolecular":

The same assembly principles can by and large be observed in biological systems (e.g. DNA). It is precisely the application of these concepts with the ultimate aim of developing materials with innovative properties that the "Matière Molle et Chimie" Laboratory has been focusing on since 2000. Over the last few years, the Laboratory has developed various supramolecular materials from molecules of different nature (small molecules derived from vegetable oils, large molecular chains in existing polymers) by creating hydrogen bonds between these molecules whose particularity, unlike conventional chemical bonds, is to be "reversible" under the effect of temperature.

From concept to everyday applications

This new approach to the chemistry of materials is opening up the way to wide-ranging innovations and developments. Materials can indeed be developed from small molecules derived from vegetable oils, and be processed or applied at low temperature, with a behavior in the solid state that is typical of a polymer with large molecular chains, e.g. sturdiness and strength.

Another typical application is the example of an existing conventional polymer which is modified by integrating these temporary bonds, and so will be able to combine excellent fluidity at processing temperature with outstanding properties in the solid state, which are identical to, if not better than, those of an existing non-modified polymer.

Yet another highly promising application can already be envisaged for bitumens laid on high-traffic carriageways: these specialty bitumens are modified with polymers which make them more hard-wearing, albeit to the detriment of their viscosity; they then have to be heated at high temperature (180°C) for a long period of time for their preparation and application, which are highly energy-intensive operations. By adding to the bitumen an additive of vegetable origin derived from supramolecular chemistry, it is possible to lower to 140°C the temperature needed to heat up these bitumens prior to application while keeping their mechanical strength, and facilitate their recycling.

For the self-healing rubber, Leibler has a deal with French chemical company Arkema to develop and commercialize the material. Arkema was a key industrial partner in this research, in particular through its expertise in nanostructured materials, and is entering the phase of commercial development for several materials derived from this research. Leibler would like to see the new rubber used in toys: "children like to break things, if you could heal them it would be very nice."

Arkema is one of the first chemicals producers to develop products based on the supramolecular chemistry technology earmarked for industrial production. The company is also a global leader in the development of biopolymers with superior qualities (such as vegetable oil based bioplastic pipelines for use in the oil exploration and extraction industry, superior to petroleum based riser pipes - more here; or bioplastic fuel lines for aggresive biodiesel - see here).

References:

Cordier, P. , Tournilhac, F. , Soulié-Ziakovic, C. & Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly, Nature 451, 977–980 (2008), doi:10.1038/news.2008.611.

Nature: Self-healing rubber bounces back - February 20, 2008.

Nature: videos of the self-healing rubber.

Arkema: Supra-molecular chemistry yields new materials with outstanding properties - February 21, 2008.

Biopact: The bioeconomy at work: robust bioplastic used for off-shore oil riser pipes - April 18, 2007

Biopact: The bioeconomy at work: bioplastic fuel lines to handle aggressive biodiesel - December 13, 2006

Article continues

posted by Biopact team at 11:08 PM 0 comments links to this post