UN's FAO: bright future for sustainable biofuels DR Congo

Biopact was originally founded by social scientists from Belgium, with working experience in the Democratic Republic of Congo, one of the poorest countries in the world. Several years ago they started looking at ways in which this large African country, coming out of the most gruesome and lethal war since WWII, could benefit from its vast natural resources which, up till now, have been the cause of multiple conflicts. They found that the emerging bioenergy market could offer unique chances for truly sustainable development, socio-economic stabilisation, rural development and mass poverty alleviation in this mainly rural country. Dr. Josef Schmidhuber, senior economist at the United Nations Food and Agriculture Organisation (FAO), now confirms this vision.

Biopact was originally founded by social scientists from Belgium, with working experience in the Democratic Republic of Congo, one of the poorest countries in the world. Several years ago they started looking at ways in which this large African country, coming out of the most gruesome and lethal war since WWII, could benefit from its vast natural resources which, up till now, have been the cause of multiple conflicts. They found that the emerging bioenergy market could offer unique chances for truly sustainable development, socio-economic stabilisation, rural development and mass poverty alleviation in this mainly rural country. Dr. Josef Schmidhuber, senior economist at the United Nations Food and Agriculture Organisation (FAO), now confirms this vision.Biopact often refers to the vast agricultural potential in Central Africa and especially in the DRC, a country the size of Western Europe, which contributes much to the estimates by researchers from the International Energy Agency's Bioenergy Taskforces, who put the entire continent's explicitly sustainable bioenergy potential at more than 350 Exajoules per year by 2050 (previous post). Sustainable, that is, without any deforestation and after meeting all food, fiber and fodder needs of growing populations.

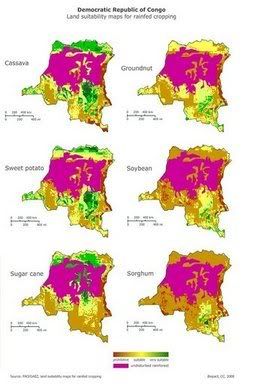

The UN's Food and Agriculture Organisation now says that, indeed, Congo is one of Africa's most promising biofuels producers due to its vast amount of farmland suited to a range of crops from palm oil to soybeans, from sugarcane to grasses. Better still, the fuels and bioenergy can be produced in a sustainable way, it says, without threatening the DRC's unique rainforests - so large is the non-forest land base (maps, click to enlarge).

Dr. Josef Schmidhuber, senior economist at the FAO, told Reuters the DRC had 80-115 million hectares of unused arable land, 4 million of which could be irrigated. All of the land in question is non-forest land. Congo currently utilizes less than 5 percent of all this potential arable land.

The DRC and many of the African countries have an enormous agri-ecological potential. They have production potential for more than (sugar) cane: palm oil, maize, jatropha, cassava even soybeans - whatever is suited to tropical and highland conditions. - Dr. Josef Schmidhuber, senior economist, FAOMany countries seeking to produce biofuels have run into problems over the use of land, and environmental campaigners have accused palm oil growers in Indonesia, for instance, of cutting down rain forests to make room for feedstock. Biopact has tried to show that this focus is too narrowminded and that it draws attention away from the vast potential for truly sustainable biofuels across Central Africa. Biofuel production there would have multiple environmental, social and economic benefits to some of the poorest nations on earth, such as the DRC.

Schmidhuber confirms that the environmental fears often raised against biofuels in the tropics need not be an issue in Congo, home to the world's second largest rainforest, given the enormous amount of arable land outside precious rain forest areas.

What is more, using land for energy crops does not come at the expense of food production and would even contribute to protecting the environment because it would allow farmers to become more efficient, instead of relying on destructive and inefficient slash and burn techniques that level rainforests. Producing bioenergy from domestic agriculture could boost productivity, as a lack of energy is a key factor holding back agricultural productivity and food production, Dr. Schmidhuber said.

This is a thesis Biopact has always stressed: without abundant, modern and affordable energy and fuels, food production itself and socio-economic development in general are threatened, with the environment being the first victim (we're not even talking about the environmental impacts of war and underdevelopment, which have wrecked all conservation efforts in Congo. The country's primates, for example, are being killed as a result of a lack of access to modern energy, which forces people into the forests to gather wood for charcoal). This type of energy poverty as well as catastrophically high oil prices can be tackled by efficient biofuel and bioenergy production:

energy :: biomass :: bioenergy :: biofuels :: sustainability :: energy poverty :: social conflict :: peace :: rural development :: poverty alleviation :: food security :: agriculture

energy :: biomass :: bioenergy :: biofuels :: sustainability :: energy poverty :: social conflict :: peace :: rural development :: poverty alleviation :: food security :: agriculture DRC, in central-eastern Africa, is rich in natural resources with a land area the size of western Europe but years of civil war have hindered economic growth and inward investment. Schmidhuber said it would currently be difficult to produce biofuels for export and Congo would benefit first by providing fuel for domestic consumption.

You have to bear in mind barely 1 percent of the rural population has access to electricity ... There's a need for empowerment and to be sufficient in energy and not just food. - Dr. SchmidhuberHe said capital investment in the sector from abroad depended on the scale of demand, referring to China's well-established interest and investment activity in Congo.

Domestic support seems to be there, there is a government programme that essentially stresses that one should try to explore energy options with the objective to produce motor-fuel and electricity. - Dr. SchmidhuberLatest World Bank figures show $402 million of foreign direct investment went to Congo in 2005. Other countries with similar potential to supply themselves with biofuels are, amongst others, Zimbabwe, Mozambique and Malawi, he added.

Biopact has been studying the bioenergy potential in Congo for a long time and developed several scenarios for their development and impacts on the country's economy. Members of the organisation were also involved in the creation of a 'biomass action plan' to phase out nuclear power in Belgium, by replacing nuclear energy with biomass from the DRC. The plan was launched last year by the Flemish social-democrats (previous post).

Biopact is currently working on a large project that looks at developing a 'fuel corridor' alongside the Congo River and its tributaries, - the country's main transport routes - as a way to improve traffic on these waterways. Fuel shortages inland are frequent and keep millions of farmers in abject poverty, because they cannot bring their products to market, trade and develop. By building decentralised biofuel production units alongside the rivers, which provide local economic opportunities and employment, this situation could be improved upon in a dramatic way.

References:

Reuters: Bright future for biofuels in Congo, UN says - January 7, 2008.

FAO Terrastat: database on land resources.

FAO Land and Water Development Division: Land Suitability Maps for Rainfed Cropping, database and maps.

FAO/IIASA: Global Agro-Ecological Zones, showing the potential for a range of crops.

Wildlife Direct: Congo gorilla protection blog (showing how lack of access to modern bioenergy drives rainforest destructive charcoal production).

Biopact: A look at Africa's biofuels potential - July 30, 2006

Biopact: Biomass 'reserve' to reduce risk of uranium shortage - perspectives from Belgium - August 15, 2007

Article continues

--------------

--------------

BlueFire Ethanol Fuels Inc, which develops and operates carbohydrate-based transportation fuel production facilities, has secured capital liquidity for corporate overhead and continued project development in the value of US$15 million with Quercus, an environmentally focused trust.

BlueFire Ethanol Fuels Inc, which develops and operates carbohydrate-based transportation fuel production facilities, has secured capital liquidity for corporate overhead and continued project development in the value of US$15 million with Quercus, an environmentally focused trust.

A large scale five-year trial of switchgrass as a bioenergy crop on farmland in the Midwestern United States found that when the perennial is converted into cellulosic ethanol it yields 540% more renewable energy than the non-renewable energy put into producing the fuel. This is a considerbly higher yield than previous estimates which were based on small scale research plots (smaller than 5m²) and on

A large scale five-year trial of switchgrass as a bioenergy crop on farmland in the Midwestern United States found that when the perennial is converted into cellulosic ethanol it yields 540% more renewable energy than the non-renewable energy put into producing the fuel. This is a considerbly higher yield than previous estimates which were based on small scale research plots (smaller than 5m²) and on

Tuesday, January 08, 2008

Biofuel enzyme developer Verenium achieves technical milestone, receives $500,000 from Syngenta

The milestone deals with the development of 'third-generation' biofuel systems, based on crops that grow their own bioconversion enzymes - in this case, they turn corn starch into sugars. This eliminates the need for biorefineries to add separate liquid enzymes to process starch into ethanol, reducing costs (previous post).

A core component of the research effort utilized Verenium's DirectEvolution technology to engineer the properties of a key enzyme - alpha amylase - in the biosynthesis of starch.

The technology is based on the knowledge that proteins are large, complex molecules made up of a unique sequence of smaller subunits called amino acids. There are 20 different naturally occurring amino acids, each having unique chemical properties, which cause the protein to fold up into distinct three-dimensional structures that define their particular function. A change in just a single amino can greatly affect the function of a protein such as an enzyme or an antibody. It is a cell's genes that contain a specific DNA sequence that dictates the order and type of amino acids that make up each protein made by the cell.

Verenium possesses patented, state-of-the-art gene evolution technologies, which it calls its 'DirectEvolution' platform, that enable the optimization of proteins at the DNA level. Two complementary methods comprise Verenium's DirectEvolution platform: Gene Site Saturation Mutagenesis (GSSM) and Tunable GeneReassembly (TGR) technologies. The suite of DirectEvolution technologies provides potentially significant competitive advantages, including the ability to generate the broadest amount of genetic sequence diversity, the ability to make fine changes across an entire gene, and the freedom to use unrelated genes when recombining starting genes. Additionally, both GSSM and TGR technologies are able to modify codons to achieve increased protein expression for manufacturing without changing the fundamental amino acid sequence (schematic, click to enlarge).

GSSM technology creates a family of related proteins that all differ from a parent protein by at least a single amino acid change at any defined position or at each position along the protein sequence. GSSM technology can produce all possible single amino acid substitutions at every position within a protein sequence, removing the need for prior knowledge about the protein structure and allowing all possibilities to be tested in an unbiased manner. The library of variants created using GSSM technology is then available to be expressed and screened for improved properties. The GSSM library can be screened for novel enzymes with characteristics such as increased ability to function at high temperature or a targeted pH range, increased reaction rate or resistance to deactivating chemicals:

Beneficial mutations identified from a GSSM screen can then be combined in a combinatorial fashion using the 'GeneReassembly' process to create a superior version of the parental protein. GeneReassembly technology allows blending of gene sequences independent of sequence homology. Multiple variations can be introduced at precise positions within the genes. The complexity of the variant library can be fine-tuned by the number of parental genes used and the average number of variations used in the reaction. Moreover, the number of variations can be modulated to reflect the resilience of the targeted gene family to mutations. In addition, any structural information available can be incorporated into the sequence design, and codon usage can be optimized during the reassembly process to maximize expression in the selected production host. Verenium’s GeneReassembly method represents the next generation of gene-blending evolution methods.

Verenium applied these DirectEvolution technologies to develop the key enzyme embedded into Syngenta's genetically modified strain of corn that grows the bioconversion enzyme. This corn strain expresses high levels of alpha amylase — a thermal-tolerant digestive enzyme developed by Verenium that turns the corn’s starch into sugar for ethanol. The engineered plants are designed to reduce costs by eliminating the need for mills to add liquid enzymes. The Corn Amylase (Amylase-T) seeds do not increase the yield, rather they make corn easier to process which translates into substantial savings for mill operators. Syngenta has announced that pilot trials have been successfully conducted and that it anticipates launch of this product in 2008.

The company earlier succeeded in utilizing its DirectEvolution suite to reassemble genes from microorganisms found in the deep sea to produce a high-performance enzyme for economical ethanol production - its first commercially available biofuel enzyme, Fuelzyme-LF.

Verenium Corporation is a leader in the development and commercialization of cellulosic ethanol, an environmentally-friendly and renewable transportation fuel, as well as high-performance specialty enzymes for applications within the biofuels, industrial, and health and nutrition markets. The Company possesses integrated, end-to-end capabilities in pre-treatment, novel enzyme development, fermentation, engineering, and project development and is moving rapidly to commercialize its proprietary technology for the production of ethanol from a wide array of feedstocks, including sugarcane bagasse, dedicated energy crops, agricultural waste, and wood products. In addition to the vast potential for biofuels, a multitude of large-scale industrial opportunities exist for the Company for products derived from the production of low-cost, biomass-derived sugars.

Verenium's Specialty Enzyme business harnesses the power of enzymes to create a broad range of specialty products to meet high-value commercial needs. Verenium's world class R&D organization is renowned for its capabilities in the rapid screening, identification, and expression of enzymes—proteins that act as the catalysts of biochemical reactions.

Verenium operates one of the nation's first cellulosic ethanol pilot plants, an R&D facility, in Jennings, Louisiana and expects to achieve mechanical completion of a 1.4 million gallon-per-year, demonstration-scale facility to produce cellulosic ethanol by the end of the first quarter of 2008. In addition, the Company's process technology has been licensed by Tokyo-based Marubeni Corp. and Tsukishima Kikai Co., Ltd. and has been incorporated into BioEthanol Japan's 1.4 million liter-per-year cellulosic ethanol plant in Osaka, Japan – the world's first commercial-scale plant to produce cellulosic ethanol from wood construction waste.

Schematic: suite of protein and enzyme discovery tools: mutating amino acids, screening improved proteins and combining detected changes to find the most promising protein. Credit: Verenium.

References:

Verenium Corporation: Verenium achieves financial milestone in research collaboration with Syngenta - January 8, 2007.

Verenium: DirectEvolution technology.

Biopact: Syngenta to trial third generation biofuel crop that grows its own bioconversion enzyme - November 12, 2007

Biopact: Diversa and Celunol merge to become Verenium - June 21, 2007

Biopact: Third generation biofuels: scientists patent corn variety with embedded cellulase enzymes - May 05, 2007

Biopact: Agrivida and Codon Devices to partner on third-generation biofuels - August 03, 2007

Article continues

posted by Biopact team at 10:45 PM 0 comments links to this post